文章编号:1004-0609(2014)11-2711-07

AZ31镁合金连续挤压扩展成形流动速度分布规律

杨俊英,高 飞,万萌萌,宋宝韫

(大连交通大学 连续挤压教育部工程研究中心,大连 116028)

摘 要:为了解镁合金连续挤压扩展流动规律与工艺条件的关系,基于DEFORM-3D软件,建立镁合金的刚塑性有限元模型,通过数值模拟分析连续挤压过程坯料沿纵向对称面上的速度演变规律,探讨挤压轮转速对坯料各层面速度分布的影响机制。结果表明,在连续挤压过程中,金属流动速度在各变形区呈不同变化趋势。轮槽区的速度呈现由轮槽底面向封料面逐渐降低的分布形态;直角弯曲区的流道底部速度最高;扩展区由中心向两侧流动速度逐渐减小;在阻流区和模具区,流动速度的差别减小。随着挤压轮转速的增大,直角弯曲区和扩展区各层面金属的速度差值增大,流动的不均匀程度增加。连续挤压过程中金属的这种流动分布特点缘于轮槽面的摩擦驱动力与型腔壁摩擦阻力的相互作用。

关键词:AZ31镁合金;连续挤压;数值模拟;流动速度

中图分类号:TG379 文献标志码:A

Flow velocity distribution rule of AZ31 magnesium alloy during continuous extrusion expansion forming

YANG Jun-ying, GAO Fei, WAN Meng-meng, SONG Bao-yun

(Engineering Research Center of Continuous Extrusion, Ministry of Education,

Dalian Jiaotong University, Dalian 116028, China)

Abstract: For understanding the relationship between the expansion flow and process conditions, based on the DEFORM-3D software, the model of rigid-plastic FEM was established. The velocity evolution rule on the longitudinal symmetry plane was analyzed during the forming process through numerical simulation. The effect of extrusion wheel velocity on the metal velocity distributions of all surfaces was investigated. The results show that the metal velocity presents various changing forms in different deformation regions. In the groove region, the velocity gradually decreases from groove bottom to enclosing surface. In the rectangular bending region, the velocity at the channel bottom is the highest. In the expansion region, the velocity gradually decreases from the center to the two sides. In the choked flow and die regions, the flow velocity differences are smaller than those of other regions. With the increase of wheel velocities, in the rectangular bending and expansion regions, the differences of the highest and lowest velocities and the non-uniformity of flow increase for all surfaces. The flow distribution characteristics of the continuous extrusion are induced by the interaction between the driving force of the wheel groove and the friction resistance of the cavity wall.

Key words: AZ31 magnesium alloy; continuous extrusion; numerical simulation; flow velocity

连续挤压扩展成形是一种利用摩擦力驱动小截面杆坯进入扩展型腔内,经过扩展流动形成大截面产品的变形过程[1-4]。它具有流程短、节能、环保和高效等优点。近年来,连续挤压在扩展成形技术方面取得了很大的进步,推动了连续挤压技术在更大范围的推广应用[5-8]。由于镁合金为密排六方结构,成形条件苛刻,因此,将连续挤压技术应用到镁合金加工领域,会对镁合金加工技术的发展起到推动作用。

采用连续挤压扩展成形方法加工镁合金,需要研究连续挤压扩展流动对镁合金成形性的影响。连续挤压扩展成形的特点决定了它在轮槽区和扩展型腔区均存在流动的不均匀性,这种流动不均匀性影响着产品的制造工艺和产品质量,一些学者针对扩展成形中存在的问题展开了相关研究。代娜娜[9]采用塑性泥通过1:1物理模拟方法研究了扩展挤压过程,发现型腔中心区域纵向流动速度最快,并逐渐向两侧减小。运新兵等[10-12]通过数值模拟方法探讨了金属在型腔内的流动过程,分析了模口处流速均方差的变化,认为具有促流角的圆鼓形阻流模可使金属流动速度差减小。吴鹏越等[13-14]针对大宽厚比铜扁线,研究了型腔宽度和阻流模的阻碍角对模口处流速均方差、模具载荷、等效应变场和应力场的影响规律。这些工作主要考虑了坯料在扩展腔内沿横向的速度场分布形态,对于金属沿纵向方向的流动规律,仍缺少探讨。实际上,在金属的变形流动中,沿纵向和横向的流动是相互协调的,认识连续挤压扩展成形过程沿纵向的速度分布规律,可以更好地掌握连续挤压的扩展成形特点,从而对解决流动不均匀问题、提高组织和性能均匀性具有重要意义。

在此,本文作者以AZ31镁合金为研究对象,建立连续挤压扩展成形有限元模型,采用分区和分层的方法,探讨在连续挤压过程中坯料沿纵向对称面上的速度演变规律,并研究挤压轮转速对AZ31镁合金上表面、中层面和下表面层速度分布的影响机制。

1 镁合金连续挤压有限元模拟

1.1 有限元模型的建立

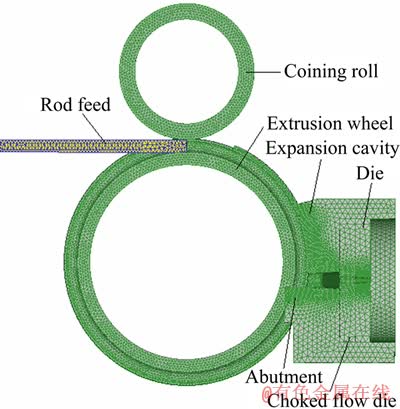

图1所示为采用Deform3D软件建立的镁合金连续挤压扩展成形的有限元模型。考虑到成形部件结构的对称性,计算取实际结构的1/2,同时忽略溢料对流动过程的影响,以提高模拟效率。

1.2 模拟参数的设置

图1 连续挤压有限元模型示意图

Fig. 1 Schematic diagram of continuous extrusion FEM model

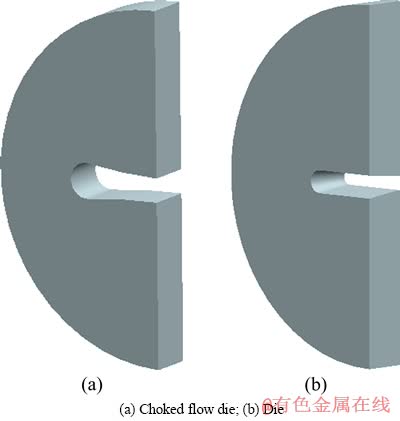

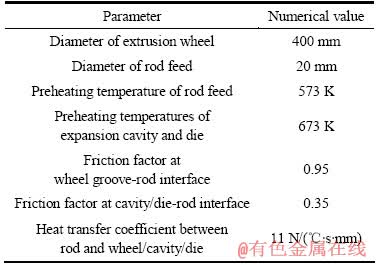

在有限元模拟中,将AZ31镁合金杆坯作为塑性体,采用四面体单元划分网格,其初始单元数为22504。挤压轮、压实轮、腔体等采用H13钢材料,并作为刚性体处理。考虑到板材扩展成形时,型腔中部金属流动较快,而两侧较慢,为减小这种差异性,在型腔内设置阻流模,阻流模中部流道适当减窄,两侧流道加宽,阻流模和模具的结构如图2所示。坯料与工模具的接触面上采用剪切摩擦模型处理,数值模拟相关输入参数见表1[15-16]。

对于AZ31镁合金,采用的本构方程为[17]

(1)

(1)

式中: 为应变速率;

为应变速率; 为应力;R为摩尔气体常数;T为温度。

为应力;R为摩尔气体常数;T为温度。

图2 连续挤压型腔内的阻流模和模具结构示意图

Fig. 2 Schematic diagrams showing die structure of continuous extrusion chamber

表1 数值模拟的初始参数

Table 1 Initial parameters of numerical simulation

2 分析与讨论

2.1 连续挤压过程坯料在纵向对称面上的速度演变规律

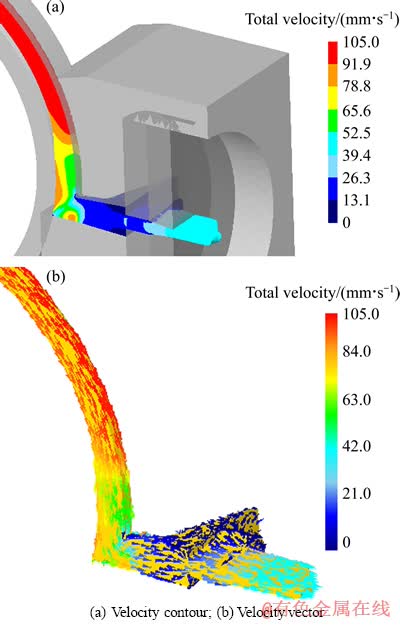

图3 连续挤压扩展成形过程坯料在对称面上的速度场分布

Fig. 3 Velocity field distribution on symmetry plane during continuous extrusion expansion forming

数值模拟挤压轮转速为5 r/min,挤出产品尺寸为80 mm×8 mm的连续挤压过程,其速度分布云图和矢量图如图3所示。可见,坯料沿纵向对称面的速度存在一定的差异。由速度分布云图可见,速度存在3个明显的区间,高速区、过渡区和低速区。在坯料未完全充满轮槽的区域,其速度处于100 mm/s左右,构成高速区;在坯料充满轮槽与扩展型腔封料面构成的区域,形成过渡区。封料面对坯料的摩擦阻力作用改变了坯料的流动形态,使坯料在此区域流动速度呈现不均匀分布,尤其在阻挡块附近;阻挡块限制了金属的流动,使金属流动方向发生改变,造成速度的变化范围大,速度差增加,速度变化范围在40~90 mm/s;在扩展型腔区,由于型腔的横截面积增加,允许金属实现横向扩展流动,形成低速区,速度约为20 mm/s。由速度矢量图可见,在不同的区域,金属的流动方向有所区别。在高速区,坯料在挤压轮驱动下沿轮槽周向流动;在过渡区,沿圆周的运动受到阻挡块阻碍,流动方向由沿轮周方向转动到沿轮的径向方向,发生约90°的转变;在低速区,由于允许金属发生横向扩展,导致流动向纵向和横向两个方向进行,金属进入阻流区和模具区,横向尺寸不再变化,金属流动速度演变为沿纵向的流动。

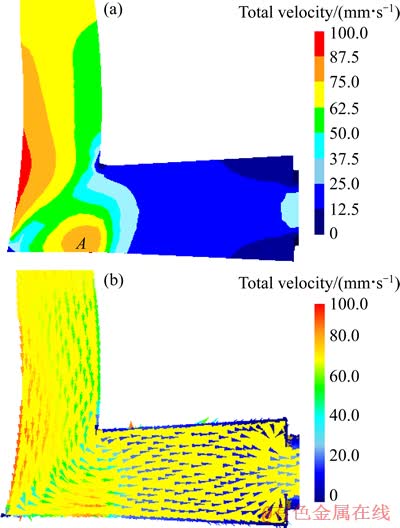

图4 轮槽区、直角弯曲区坯料在对称面上的速度分布

Fig. 4 Velocity field distribution on symmetry plane in regions of wheel groove (a) and rectangular bending (b)

图4所示为轮槽区和直角弯曲区的速度分布云图及矢量图。可见,从速度分布上看,在轮槽区,挤压轮轮槽底侧的坯料速度最大,封料面侧的速度最小,表现为由轮槽底面向封料面,速度逐渐降低的分布形态。在直角弯曲区,角部附近区域的速度最小,随与角部距离的增加,速度增加,但在靠近流道底部区域的速度大,流道上部的速度小,表现为由流道底部向上部速度逐渐降低的分布形态。与轮槽区相比,型腔通道区坯料的整体速度减小,沿流道高度方向的速度差也减小。从坯料各点的流动方向分布看,从轮槽到型腔通道,坯料各点速度发生了等于或大于90°的转向。由于各区域速度的相互制约作用,使区域A处形成了一个速度相对较高的区域。

由图4可知,连续挤压过程中,坯料的流动形态与轮槽和型腔结构密切相关。在轮槽区,坯料的3个面受到旋转挤压轮摩擦驱动力的作用,牵动其流动,另一个面则受到封料面摩擦阻力的作用,阻止其流动,这种方向相反的摩擦力的相互作用致使坯料的流动模式呈现出由槽底区域的坯料拉动其他区域坯料流动的形式,从而表现出速度是由槽底向封料面速度逐渐降低的形态。在坯料发生转弯区域,尽管靠近轮槽底部区域的坯料的流动路径大于其他区域的流动路径,但由于这部分坯料处于轮槽摩擦驱动力作用大的区域,因而,仍比通道上部区域坯料的流动速度大,表现为由流道底部向上部,速度逐渐降低的分布形态。在型腔通道区,坯料的4个面均受到型腔壁的摩擦阻力作用,作用力的方向一致,这有助于降低坯料各点的速度差,相对而言,中部坯料受到型腔壁的摩擦力作用小,从而表现出速度高于边部区域。

图5所示为坯料由轮槽到挤出模口的流动全过程的速度分布情况。结合图4可知,在这个过程中,坯料由轮槽区经型腔通道充填到型腔中。在型腔中,根据流动特征,将坯料的流动划分为3个区域:扩展区、阻流区和模具区。可见,在扩展区,坯料流动是一个由小截面变为大截面的过程,从而表现出坯料的速度整体减小;同时,在此区域,中心区域的流动速度大,由中心向两侧,流动速度逐渐减小,并且随着与型腔入口距离的增加,中间与两侧的速度差增大。在阻流区,坯料的流动方向一致,使速度趋于均匀。在模具区,随与模具出口距离的减小,由于流动断面减小,导致速度逐渐增大。

坯料在扩展型腔中的速度分布特点缘于连续挤压这种特殊的变形形式,坯料充填到扩展区后,边部区域的坯料受到型腔壁摩擦阻力的作用,流动速度处于较低值,而型腔壁摩擦力的作用程度随与型腔壁的距离增加而降低,从而造成芯部区域与两侧的速度差增大。从扩展区进入阻流区,流动通道的高度尺寸从28 mm减小为13 mm,尺寸减小了2倍多。型腔高度尺寸减小,型腔壁摩擦力的作用程度大,从而使芯部区域的坯料受到的阻碍作用叠加,起到了减小边部与中间的速度差的作用;在模具区,随与模具出口距离的减小,金属流动通道的横截面积减小,导致流动速度逐渐增大。同时由于型腔壁的摩擦作用,使中心与边部形成一定的速度差。

图5 扩展区、阻流区和模具区坯料在对称面上的速度分布

Fig. 5 Velocity field distribution on symmetry plane in regions of expansion, choked flow and die

2.2 挤压轮转速对坯料各层面速度分布的影响

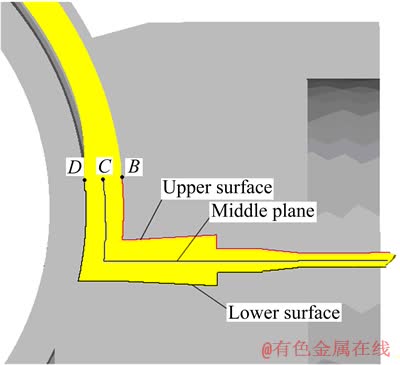

挤压轮转速是决定连续挤压工艺条件和坯料流动均匀性的重要参数,为了研究转速对坯料不同层面上速度分布的影响,如图6所示,将型腔封料面-型腔通道上侧-扩展区上侧-阻流区上侧-模具区上侧定义为研究的上表面,将轮槽底侧-型腔通道下侧-扩展区下侧-阻流区下侧-模具区下侧定义为研究的下表面,取上下表面之间区域的中心作为中层面。针对定义的这3个层面,从数值模拟结果中提取速度值。上表面、中层面和下表面提取数据的起点位置分别为B、C和D点。

图6 上表面、中层面和下表面位置示意图

Fig. 6 Schematic diagram of sampling point locations on upper surface, middle plane and lower surface

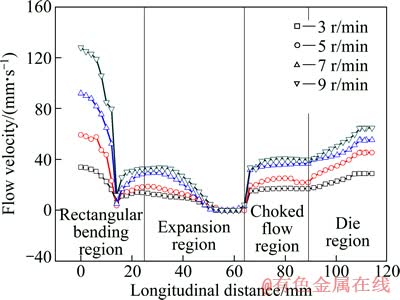

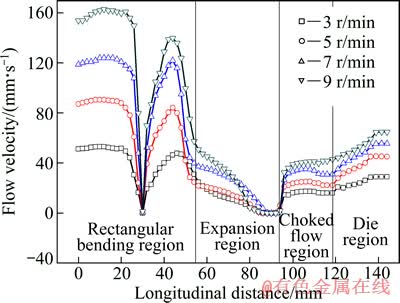

图7所示为挤压轮转速对上表面层流动速度的影响。横轴为以直角弯曲区的B点为零点沿上表面展开的纵向距离(见图6)。可见,上表面层从直角弯曲区到模具区,流动速度呈现明显的波动状况。在直角弯曲区,挤压轮转速分别为3、5、7和9 r/min时,对应的流动速度从约35、60、92和128 mm/s斜线下降到速度波谷(13 mm处),转速越大,下降斜率越大。在直角弯曲区和扩展区之间(13~64 mm范围),速度呈单峰状分布,波峰的位置基本相同,转速越大,峰值越高,波谷与波峰速度的差值从10 mm/s增大到30 mm/s。在扩展区(51~64 mm范围)形成一个速度接近零值的流动死区。在阻流区,流动速度变化较小。在模具区,不同转速下随纵向距离的增加,流速均逐渐增大。

图7 挤压轮转速对上表面层金属流动速度的影响

Fig. 7 Effect of extrusion wheel velocity on flow velocities of upper surface

图8 挤压轮转速对中层面金属流动速度的影响

Fig. 8 Effect of extrusion wheel velocity on flow velocities of middle plane

图8所示为挤压轮转速对中层面流动速度的影响。可见,从直角弯曲区到扩展区,流动速度呈现明显的下降趋势,从阻流区到模具区,流动速度又呈增加趋势。在直角弯曲区,对应挤压轮转速3、5、7和9 r/min,C点的流动速度分别约为40、67、101和135 mm/s,但随纵向距离的增加,流动速度呈波动性下降的状态。在扩展区,速度继续沿斜线下降,转速越大,下降斜率越大。在直角弯曲区和扩展区,最高与最低速度的差值从30 mm/s增大到110 mm/s。在阻流区,流速变化不明显。在模具区,流速逐渐增大到稳定值。

图9所示为挤压轮转速对下表面层流动速度的影响。可见,从直角弯曲区到模具区,流动速度呈现大幅波动状况,其波动程度随挤压轮转速的增加而增加。在直角弯曲区,与轮槽底部接触的区域(0~20 mm范围),流动速度最大,对应挤压轮转速3、5、7和9 r/min,流动速度分别为52、87、120和155 mm/s,在直角转弯处(30 mm处)形成速度波谷,各转速下的流动速度均直线下降到接近零值,表明在这个区域存在流动死区。坯料在流过死区后,流动速度直线上升,在位于阻挡块附近的A处(见图4)形成速度峰值,转速越大,峰值越高,波谷与波峰速度的差值从50 mm/s增大到140 mm/s。在扩展区,流动速度呈降低趋势,在84~94 mm区域,形成一个速度接近零值的流动死区。在阻流区,流动速度变化较小。在模具区,随纵向距离增加,流动速度逐渐增大。

图7、8和9表明,挤压轮转速对各层面流动速度的影响程度是不同的。对于中层面,由于金属的流动受型腔壁阻力的影响较小,流动的均匀性较好,随挤压轮转速的增加,各区域的流动速度呈均匀增加状态。对于上下表面层而言,在直角弯曲区和扩展区形成两个死区,一个死区是由于流动方向改变导致的坯料流动不畅形成,另一个是由于扩展区的通道高度大于阻流区造成的。随挤压轮转速的增加,并未能改变流动死区的状态,但明显增加了其他区域的流动速度,表现出流动速度的波动随挤压轮转速的增加而增加。可见,增加挤压轮转速加剧了流动速度的不均匀分布形态,这可能会影响到各区域金属的变形和再结晶的不均匀程度,造成微观组织和性能有所不同。

图9 挤压轮转速对下表面层金属流动速度的影响

Fig. 9 Effect of extrusion wheel velocity on flow velocities of lower surface

3 结论

1) 在连续挤压过程中,金属流动速度在各变形区呈不同形态。轮槽区的速度呈现由轮槽底面向封料面逐渐降低的分布形态;直角弯曲区的流道底部速度最高;扩展区由中心向两侧流动速度逐渐减小;阻流区和模具区的流动速度变化较小。

2) 随着挤压轮转速的增大,直角弯曲区和扩展区各层面金属的速度差值增大,流动的不均匀程度增加。

3) 连续挤压过程中金属的流动分布特点缘于轮槽面的摩擦驱动力与型腔壁摩擦阻力的相互作用,导致坯料上下表层与中间层的流动速度偏差明显。

REFERENCES

[1] MITCHELL K J. Production of wire and allied products by the conform process[J]. Metallurgia, 1982, 8(11): 584-589.

[2] ETHERINGTON C, SLATER H K. The extrusion of aluminum and its alloys by the CONFORM process[C]//Proceedings of the Third International Aluminum Extrusion Technology Seminar. Atlanta: Aluminum Association, 1984: 31-38.

[3] MADDOCK B. Aluminum rod and other products by CONFORM[J]. Wire Industry, 1987, 54(12): 728-731.

[4] LANGERWEGER J, MADDOCK B. Recent developments in CONFORM and CASTEX continuous extrusion technology[J]. Light Metal Age, 1988(8): 23-28.

[5] GREEN D. Continuous extrusion forming of wire sections[J]. Journal of the Institute of Metals, 1972, 100: 295-300.

[6] 谢玲玲, 宋宝韫. 铜母线连续挤压扩展成形过程的三维有限元数值模拟[J]. 锻压技术, 2005(3): 72-75.

XIE Ling-ling, SONG Bao-yun. 3D-FEM mathematical simulation of CONFORM extending-forming process for copper busbar[J]. Forging & Stamping Technology, 2005(3): 72-75.

[7] YUN X B, YOU W, ZHAO Y, LI B, FAN Z X. Continuous extrusion and rolling forming velocity of copper strip[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1108-1113.

[8] CAO J R, WEN J L, DING H, WANG Z D, LI Y L, GUAN R G, HOU H. Force analysis and experimental study of pure aluminum and Al-5%Ti-1%B alloy continuous expansion extrusion forming process[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 201-207.

[9] 代娜娜. 大宽厚比铜排连续挤压物理模拟与生产实践[D]. 昆明: 昆明理工大学, 2012: 21-25.

DAI Na-na. Study on physical modeling and production practice of continuous extrusion high width-thickness ratio product[D]. Kunming: Kunming University of Science and Technology, 2012: 21-25.

[10] 陈 旭, 运新兵, 赵 颖, 樊志新, 宋宝韫. 分流模结构对连续挤压扩展成形的影响[J]. 塑性工程学报, 2010, 17(2): 68-72.

CHEN Xu, YUN Xin-bing, ZHAO Ying, FAN Zhi-xin, SONG Bao-yun. Effect of the porthole structure on extending forming of copper during continuous extrusion[J]. Journal of Plasticity Engineering, 2010, 17(2): 68-72.

[11] YUN X B, YAO M L, WU Y, SONG B Y. Numerical simulation of continuous extrusion extending forming under the large expansion ratio for copper strip[J]. Applied Mechanics and Materials, 2011, 80/81: 91-95.

[12] 运新兵, 姚明亮, 赵 颖, 杨俊英, 李 冰, 宋宝韫. 阻流环及模具结构对大扩展比连续挤压成形的影响[J]. 塑性工程学报, 2011, 18(4): 1-5.

YUN Xin-bing, YAO Ming-liang, ZHAO Ying, YANG Jun-ying, LI Bing, SONG Bao-yun. Effect of the preventing mould and die structure on continuous extrusion deforming under large expansion ratio[J]. Journal of Plasticity Engineering, 2011, 18(4): 1-5.

[13] 吴鹏越, 谢水生, 吴予才, 程 磊, 黄国杰, 和优锋. 不同靴座扩展出口宽度下大宽厚比铜扁线连续挤压过程的数值模拟[J]. 机械科学与技术, 2008, 27(2): 260-263.

WU Peng-yue, XIE Shui-sheng, WU Yu-cai, CHENG Lei, HUANG Guo-jie, HE You-feng. Numerical simulation of the continuous extrusion forming of big flakiness ratio copper flat wire under different spread outlets of shoes[J]. Mechanical Science and Technology for Aerospace Engineering, 2008, 27(2): 260-263.

[14] 吴鹏越, 谢水生, 程 磊. 不同阻碍角下大宽厚比铜扁线连续挤压过程数值模拟[J]. 有色金属, 2009, 61(3): 37-40.

WU Peng-yue, XIE Shui-sheng, CHENG Lei. Numerical simulation of big flakiness ratio copper flat wire continuous extrusion forming for different hindrance angles[J]. Nonferrous Metals, 2009, 61(3): 37-40.

[15] LI L, ZHANG H, ZHOU J, DUSZCZYK J, LI G Y, ZHONG Z H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials and Design, 2008, 29: 1190-1198.

[16] KIM Y H, CHO J R, KIM K S, JEONG H S, YOON S S. A study of the application of upper bound method to the CONFORM process[J]. Journal of Materials Technology, 2000, 97(1/3): 153-157.

[17] 郭 强, 张 辉, 陈振华, 严红革, 夏伟军, 傅定发. AZ31镁合金的高温热压缩流变应力行为的研究[J]. 湘潭大学自然科学学报, 2004, 26(3): 108-111.

GUO Qiang, ZHANG Hui, CHEN Zhen-hua, YAN Hong-ge, XIA Wei-jun, FU Ding-fa. Flow stress behavior of AZ31 magnesium alloy during hot compression deformation at elevated temperature[J]. Natural Science Journal of Xiangtan University, 2004, 26(3): 108-111.

(编辑 龙怀中)

基金项目:辽宁省自然科学基金资助项目(2013020135);辽宁省教育厅资助项目(L2013186)

收稿日期:2013-12-09;修订日期:2014-08-20

通信作者:杨俊英,副教授,博士;电话:0411-84109425;E-mail:yangjy@djtu.edu.cn