铬盐生产工艺中除铝方法的研究进展

来源期刊:中国有色金属学报2013年第6期

论文作者:魏广叶 曲景奎 齐 涛 郑裕东 郭 强

文章页码:1712 - 1722

关键词:铬盐;氢氧化铝;固相法;液相法

Key words:chromium compound; aluminium hydroxide; solid phase method; liquid phase method

摘 要:主要从固相法和液相法两个方面介绍铬盐生产工艺中铝杂质的脱除方法,固相法重点介绍无钙焙烧法,无钙焙烧熟料中含铝固相产物有铁镁矿(Mg(Fe,Al)2O4)、铝硅酸钠(NaAlSiO4)和铝硅酸镁钠(Na4MgAl2Si3O12)。同时,根据铬矿成分的不同,添加含硅或含铝原料,控制SiO2和Al2O3摩尔比,使铬铁矿中的铝和硅在无钙焙烧过程中转化成为铝硅酸钠和铝硅酸镁钠。铬酸盐熟料浸出过程中,液相中铝化合物主要是铝酸盐。液相法脱除铝杂质与体系的碱浓度密切相关。低碱浓度时,碳分法有利于得到铬酸盐夹带少、易过滤的氢氧化铝;高碱浓度时,首先进行萃取脱碱,降低溶液中碱/铝比例,然后采用种分法得到氢氧化铝沉淀。综述了各种除铝方法的特点,并探讨了除铝方法的发展方向。

Abstract: The solid phase method and liquid phase method for aluminum removal in the chromium compound production were reviewed. The special emphasis was placed on lime free roasting process. Magnesioferrite (Mg(Fe,Al)2O4), sodium aluminosilicate (NaAlSiO4), silicic acid, aluminum magnesium sodium salt(Na4MgAl2Si3O12) are the major phases of aluminum containing compound. Certain amounts of silica dioxide or aluminum oxide and such additives, depending on the chromium containing material, are added to control the molar ratio of SiO2 and Al2O3 in order to form aluminum containing compound. The liquid phase methods is relative to the alkali concentration. For decomposition of aluminates in low alkali solution, carbonate process benefit for the production of easy filterable aluminum hydroxide with little content of chromate. For decomposition of aluminates in high alkali solution, aluminum hydroxide is obtained by seed composition following by extraction of great amount of alkali metal hydroxide and decrease of alkali/aluminum ratio. Finally, the problems and development of aluminum removal process were pointed out and analyzed.

文章编号:1004-0609(2013)06-1712-11

魏广叶1,曲景奎2, 3,齐 涛2, 3,郑裕东1,郭 强2, 3

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 中国科学院 过程工程研究所 湿法冶金清洁生产技术国家工程实验室,北京 100190;

3. 中国科学院 过程工程研究所 绿色过程与工程院重点实验室,北京 100190)

摘 要:主要从固相法和液相法两个方面介绍铬盐生产工艺中铝杂质的脱除方法,固相法重点介绍无钙焙烧法,无钙焙烧熟料中含铝固相产物有铁镁矿(Mg(Fe,Al)2O4)、铝硅酸钠(NaAlSiO4)和铝硅酸镁钠(Na4MgAl2Si3O12)。同时,根据铬矿成分的不同,添加含硅或含铝原料,控制SiO2和Al2O3摩尔比,使铬铁矿中的铝和硅在无钙焙烧过程中转化成为铝硅酸钠和铝硅酸镁钠。铬酸盐熟料浸出过程中,液相中铝化合物主要是铝酸盐。液相法脱除铝杂质与体系的碱浓度密切相关。低碱浓度时,碳分法有利于得到铬酸盐夹带少、易过滤的氢氧化铝;高碱浓度时,首先进行萃取脱碱,降低溶液中碱/铝比例,然后采用种分法得到氢氧化铝沉淀。综述了各种除铝方法的特点,并探讨了除铝方法的发展方向。

关键词:铬盐;氢氧化铝;固相法;液相法

中图分类号:TF111.3 文献标志码:A

WEI Guang-ye1, QU Jing-kui2, 3, QI Tao2, 3, ZHENG Yu-dong1, GUO Qiang2, 3

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,

Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China;

3. Key Laboratory of Green Process and Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100190, China)

Abstract: The solid phase method and liquid phase method for aluminum removal in the chromium compound production were reviewed. The special emphasis was placed on lime free roasting process. Magnesioferrite (Mg(Fe,Al)2O4), sodium aluminosilicate (NaAlSiO4), silicic acid, aluminum magnesium sodium salt(Na4MgAl2Si3O12) are the major phases of aluminum containing compound. Certain amounts of silica dioxide or aluminum oxide and such additives, depending on the chromium containing material, are added to control the molar ratio of SiO2 and Al2O3 in order to form aluminum containing compound. The liquid phase methods is relative to the alkali concentration. For decomposition of aluminates in low alkali solution, carbonate process benefit for the production of easy filterable aluminum hydroxide with little content of chromate. For decomposition of aluminates in high alkali solution, aluminum hydroxide is obtained by seed composition following by extraction of great amount of alkali metal hydroxide and decrease of alkali/aluminum ratio. Finally, the problems and development of aluminum removal process were pointed out and analyzed.

Key words: chromium compound; aluminium hydroxide; solid phase method; liquid phase method

铬盐是无机盐的主要品种之一,主要包括红矾钠、铬酸酐、重铬酸钾、重铬酸铵、碱式硫酸铬、氧化铬等[1]。目前,中国铬化合物产量已占全球的40%[2]。铬盐生产的主要方法是铬铁矿氧化焙烧法。最早实现工业化的是有钙焙烧法,已经实施和正在进行试验的新技术[3],包括无钙焙烧法[4-7]、钾碱液相氧化法[8-10]、碳素铬铁-铬酸钠联合法[11-12]、铬酸钠-碳素铬铁联合法[13]、熔盐法[14]等。

随着研究的深入,脱除浸出液中的铝、硅等杂质,成为提高铬酸盐浸出液的纯度的关键。因此,降低铬酸盐浸出液的杂质含量,对于提高产品质量和促进产业发展具有重要意义。为降低铬酸盐碱性液中的铝酸盐含量,主要方式有:一是固相法,即在焙烧熟料过程中,生成铝酸盐或者铝的复盐,从而将铝固定在渣相中;二是液相法,即针对不同的焙烧技术下得到的铬酸钠浸出液,可采取加入钙/硅化合物等生成复盐沉淀法,或者水解生成氢氧化铝沉淀法等方法脱除溶液中的铝。

1 固相法

1.1 有钙焙烧

有钙焙烧法的主要原理是加入填料钙质填料进行氧化焙烧,即将铬铁矿同纯碱、含钙填料(石灰石、白云石等)、返渣(循环铬渣)混合均匀后,在回转窑内通空气氧化焙烧,熟料经浸滤、中和、酸化、蒸发、结晶制得重铬酸钠。添加钙质填料可以稀释炉料,提高氧的扩散速度,提高转化率;防止Na2CO3-Na2CrO4低共熔物在窑壁的结圈。同时,铬铁矿中的氧化铝、氧化硅和氧化铁等与氧化钙形成化合物,降低碱耗,避免或者减少了熟料浸出液中NaAlO2或者Na2SiO3的含量。其中,焙烧熟料中的铝化合物,主要包括铝酸钙、铝硅酸钠、铝硅酸钙、铁铝酸钙等。CaO与 Fe2O3、Al2O3首先生成亚铁酸钙和铝酸钙;达到熔化温度后,生成4CaO×Al2O3×Fe2O3和6CaO×2Al2O3×Fe2O3。当氧化铝与氧化铁的比值大于某个值时,主要产物为5CaO×3Al2O3。CaO与SiO2、Al2O3可形成2CaO×SiO2、3CaO×SiO2和CaO×SiO2×Al2O3等[15]。

1.2 少钙焙烧

少钙焙烧法通过提高铬矿和碱用量,增加返渣用量,提高转化率;减少填充剂如白云石和石灰石的用量,从而减少了渣中铝酸钙、硅酸钙等的生成,降低了渣量。同时,为了尽可能提高碱利用率,可选择入窑料,控制SiO2和Al2O3摩尔比,生成不溶于水的铝硅酸盐。也可以将铬矿、碱、返渣和少量消石灰混合后造粒焙烧,熟料铬转化率高,不结窑[16]。锦州铁合金集团有限公司[17]采用少钙高碱法,在焙烧窑中进行氧化焙烧。相对于有钙焙烧,少钙焙烧过程中,碱耗增加,熟料浸出液中NaOH含量由14.7 g/L增加至19.2 g/L,同时Al2O3含量由1.8 g/L增加至3.1 g/L。

采取有钙焙烧法和少钙焙烧法,有利于降低溶液中铝酸盐的含量。但是,有钙焙烧法产生大量铬渣,平均每吨红矾钠产生2~3 t铬渣;少钙焙烧可将每吨红矾钠铬渣排放量降至1.5 t[1]。铬渣含六价铬高达1%~1.5%(以Cr2O3计),特别是含有以固溶体存在的 酸溶性六价铬。铬渣长期堆放,占用大量的土地资源,所含的六价铬受雨雪淋浸而溶出,造成严重的环境污染。无钙焙烧排放铬渣量小(0.8 t每吨红矾钠)[1],将逐渐取代有钙和少钙焙烧。

1.3 无钙焙烧

1.3.1 少碱多步焙烧法

在无填料情况下,多步焙烧有利于提高碱利用率,降低碱耗。同时在焙烧过程中,由于每一步的碱量相对较少,氧化铝易于生成铝硅酸钠,进入渣相;仅有少量铝酸盐进入液相。少碱无钙焙烧的反应过程中,铬铁矿中Al2O3和SiO2首先生成NaAlO2和Na2SiO3,进一步反应生成铝硅酸钠,少碱焙烧生成钠霞石NaAlSiO4(式(1)~(3)) [4]。

Na2SiO3+SiO2+Al2O3 2NaAlSiO4 (1)

2NaAlSiO4 (1)

NaAlO2+SiO2 NaAlSiO4 (2)

NaAlSiO4 (2)

2NaAlO2+2Na2SiO3+MgCrO4+3/2O2 2NaAlSiO4+Na2CrO4+MgO (3)

2NaAlSiO4+Na2CrO4+MgO (3)

多步焙烧法主要是通过控制加入碳酸钠的化学计量百分比、焙烧温度和时间、浸出熟料所用溶液的pH值,使铝相化合物基本上都进入渣相中,从而控制浸出液中的铝酸盐含量。多步焙烧法在一定程度上降低了碱耗,如德国拜耳公司的三烧三浸法[18],碱耗降至理论量的50%左右;国内的企业如重庆民丰化工的两段焙烧法[19],碱耗量略高于理论量;新疆沈宏集团的少碱三烧三浸法[20],碱耗降至理论用量的80%。但多步焙烧使焙烧工序的时间延长,降低了单位时间的铬铁矿处理量,增加了焙烧工序的能耗。多步焙烧法可有效除铝,但是成本较高。

1.3.2 添加无钙填料

无钙焙烧可能会形成铬酸钠-碳酸钠的低共熔物,以及较低熔点的硅酸钠等,高温熔体粘附在铬矿颗粒表面,阻止铬矿的进一步氧化,并引起结圈。因此,添加适当的无钙填料有利于避免回转窑结圈。

熟料浸出后的铬渣经分选后,可作为填料返回焙烧工序。铬渣中的成分有未反应的铬铁矿Mg(Cr,Fe,Al)2O4)、镁铁矿Mg(Fe,Al)2O4)、方镁石MgO、铝硅酸镁钠和无定形物质。铬渣通过分选,除去熔点较低的无定形物质,粗渣如镁铁矿和方镁石返回焙烧以充当填料。甘肃锦世化工[21-22]以返渣为填料,加入量为铬铁矿质量的2倍,炉料不结圈。

除返渣外,镁质矿物也可单独作为无钙填料,包括菱苦土、菱铁矿、方镁石矿、水镁石或合成的氧化镁、氢氧化镁及碳酸镁[23]。镁质填料熔点高、化学惰性和易回收反复利用。镁质填料在高温下分解生成氧化镁,部分氧化镁与铝和硅等发生反应,足碱焙烧时生成铝硅酸镁钠Na4MgAl2Si3O12(式(4)~(6))[4],另外,还可能生成镁铁矿Mg(Fe, Al)2O4,将铝固溶在晶格内,减少了可溶性铝/硅酸盐的生成量,降低碱耗;同时,生成物以及游离存在的方镁石熔点较高,可避免结圈。

2Na2SiO3+Al2O3+SiO2+MgO Na4MgAl2Si3O12 (4)

Na4MgAl2Si3O12 (4)

2NaAlO2+Na2SiO3+2SiO2+MgO Na4MgAl2Si3O12 (5)

Na4MgAl2Si3O12 (5)

3Na2SiO3+2NaAlO2+MgCr2O4+3/2O2 Na4MgAl2Si3O12+2Na2CrO4 (6)

Na4MgAl2Si3O12+2Na2CrO4 (6)

另外,无填料焙烧时,铬渣主要成分为钠霞石NaAlSiO4。而钠霞石NaAlSiO4分子中SiO2和A12O3的摩尔比为2。控制熟料中可溶性铝、硅酸盐的含量,则需控制焙烧过程中SiO2和Al2O3的摩尔比。由于铬矿中铝硅成分存在较大差异,难以直接通过选择不同矿源控制SiO2和Al2O3达到目的。因此,可采取适当添加含硅或者铝物质的方式,调整焙烧过程中SiO2和Al2O3摩尔比,尽可能地使铝硅生成不溶的铝硅酸钠和铝硅酸镁钠。添加含硅原料,可选用各种含硅物质,硅砂、石英岩、硅藻土、硅胶、蛇纹岩、橄榄岩、粘土等,控制无钙焙烧熟料中SiO2和Al2O3摩尔比在1.5~2.0之间。针对高硅的铬铁矿,可选用氢氧化铝、水合氧化铝、活性氧化铝、低硅铝土矿或者铝酸钠等,以控制n(SiO2)/n(Al2O3)在1.5~2.5之间,生成不溶的铝硅酸盐[24]。

铬铁矿、碱与含铝或者硅物质共同焙烧,需要严格控制碱加入量。碱量提高,有利于提高铬的转化率,但比值过高,矿中杂质Al2O3、SiO2同苛性钠的反应也增加使碱利用率明显下降。因此,德国拜耳公司提出添加铝硅预烧法[25]。在铬铁矿与碱混合之前,根据铬铁矿成分的差异,选择性添加铝或者硅化合物,并控制n(SiO2)/n(Al2O3)在1.5~2.0之间,于800~1 000 ℃进行预烧,然后再进行氧化焙烧,铬转化率高,液相铝含量低。

添加无钙填料可有效避免窑炉结圈,有利于降低碱耗;采用添加含铝硅原料和返渣的方法,调整n(SiO2)/n(Al2O3)比值[24-25],熟料浸出液中的铝含量铝低于1%。但是返渣和填料的总量均在铬铁矿质量的的2倍以上[21-25],焙烧能耗较高。同时,铬的氧化率略低,排放的铬渣的氧化铬含量在10%以上。

1.3.3 造粒焙烧

铬铁矿添加碱化合物或者粘土等进行造粒,可提高铬铁矿的成球效果,增强球团的强度[26-27],可用于制备铬铁的预处理工序。

将铬铁矿或者铬铁精矿与碱及部分铬渣混合后,添加促进剂如硝酸钠、氢氧化钠等造粒、烘干,在回转窑中进行氧化焙烧,可有效地提高铬酸钠的转化率,并防止炉料在回转窑中结圈[28-29]。如天津化工设计院的造粒焙烧工艺[30],焙烧温度为1 050 ℃,反应时间仅为10~20 min,铬转化率达到95%以上,无结圈现象。

无钙焙烧造粒法专利中并没有明确铝相化合物的生成以及滤液中铝相化合物的含量。然而,造粒法中使用了过量的碱,并加入NaOH等,在提高焙烧过程中铬转化率的同时,可能会提高可溶性NaAlO2生成量,其具体含量与铬铁矿造粒的配碱量以及焙烧温度等相关。

1.4 冶金-化学联合法

冶金-化学联合法,即碳素铬铁-铬酸钠联合法,是一种新兴的技术。传统的方法原料为铬铁矿,而联合法则以碳素铬铁为原料,属于间接制备铬盐的技术。其原理是在火法冶炼碳素铬铁过程中使铝硅等杂质进入冶炼渣中,抑制后续反应过程中铝杂质的浸出。

传统方法是将碳素铬铁和烧碱混合后氧化焙烧,铬的转化率达到90%[11]。高温高压碱浸法[31-32]可得到含铝杂质较少的铬酸盐或者重铬酸盐溶液,同时存在的水合氧化铁或水合氧化铁、氧化铬的混合物。另外,碳素铬铁也可采用酸溶法[33-35]。以杂质量低于1%高碳铬铁为原料,经硫酸溶解、酸化,溶液中仅有微量的铝离子,调节pH值可制备氢氧化铬。

碳素铬铁法中,后续溶液中的杂质含量与铬铁的杂质成分密切相关。铬铁杂质较高时,焙烧熟料浸出后,碱性液中铝含量接近10 g/L[11]。同时,溶液中的杂质含量与后续工艺的处理方式相关。碳素铬铁碱熔法与铬铁矿的直接碱熔法相似,浸出液中铝杂质含量仍然取决于碱熔的方式包括配碱量、温度及附加剂的添加等。酸溶法处理量小,溶液中三价铬浓度高于12 g/L,调节pH值后形成氢氧化铬胶体,难以过滤和洗涤。而高温高压碱浸法流程短,成本低廉,已经中试成功,有望实现工业化应用[32]。

1.5 熔盐法

熔盐法是用大量的烧碱配以硝酸钠与铬铁矿焙烧的方法。1份铬矿配以1.8~5.0份的烧碱,0.32~0.6份的硝酸钠,在500~600 ℃进行焙烧。焙烧料在高温下呈熔融状,使高温物流入水中,降温并溶解。提高铬的转化率达99%,渣量减少至有钙焙烧工艺的17%[14]。熔盐法的缺点是碱耗高;同时,大量碱与杂质反应生成铝酸盐和硅酸盐,进入熟料浸出液中。

1.6 钾碱液相氧化法

中国科学院过程工程研究所ZHANG等[8-10]发明了钾碱亚熔盐液相氧化工艺生产氧化铬,在流动性良好的亚熔盐介质中强化气-液-固反应,可大大降低反应温度,铬渣的排放量仅为传统工艺的1/5,同时,铬的回收率可提高至99%。为强化氧化过程,采用引入硝酸钠[36]、加压浸出[37]等方式,液相氧化过程转化率高,反应温度比传统工艺低。

在亚熔盐溶出过程中,部分铝和硅会形成铝硅酸盐,进人渣相,同时,由于大量的氢氧化钠介质的存在,导致浸出液中的杂质含量急剧上升,碱性液中的铝(以Al2O3计)达到约20 g/L[38-39]。所以,高碱浓度下如何脱除液相中的铝杂质是液相氧化法的重要的步骤。

铬酸盐的制备方法还有很多,如电解氧化法、水热浸煮法和次氯酸钠法等,但是,均为正在实验室进行的技术,要实现工业化试验,还有很多未解决的问题。

2 液相法

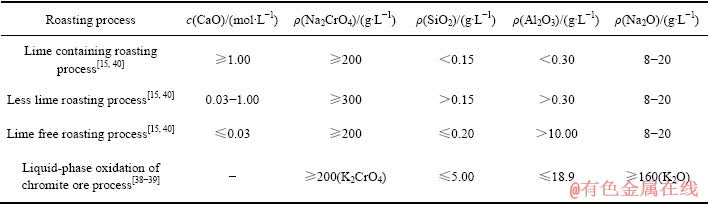

液相法指碱熔法熟料浸出液中的铝杂质地脱除,脱铝方法与溶液的碱含量和铝酸盐含量密切相关。对于传统工艺来说,有钙焙烧浸出液杂质含量很低;少钙焙烧控制条件,也可得到只含微量杂质的浸出液;无钙焙烧碱介质为碳酸盐,杂质含量相对较高,尤其是铝含量在10 g/L左右[40],如表1所列。而化工-冶金法的碳素铬铁碱法焙烧与无钙焙烧的杂质含量接近。在钾碱液相氧化法中,碱介质为烧碱且浓度较高,碱性浸出液中的铝可达20 g/L。熔盐法浸出液中亦含有大量烧碱,铝杂质浓度高,可以参考液相氧化法的除杂质方法。因此,溶液法主要针对无钙焙烧得到的熟料浸出液和液相氧化法的浸出液进行讨论,即分为碳酸盐介质-低碱浓度脱除铝和氢氧化钾(氢氧化钠)-高碱浓度脱除铝两个部分。

2.1 碳酸盐介质-低碱浓度脱除铝

2.1.1 加入硅化合物脱铝

在铬酸盐碱性液中加入可溶性的硅化合物(水玻璃、正硅酸盐、偏硅酸盐、硅酸等),硅酸根离子和铝酸根离子结合生成难溶解的铝硅复杂络合离子(式(7)),经过滤以钠硅渣的形式除去。

(7)

(7)

美国联合化学公司[41]在含有杂质铝酸盐和硅酸盐的铬酸钠水溶液中连续加入过量的、可溶性的硅化合物,可将杂质与铬酸钠溶液分离。在常压下,控制温度在95~112 ℃(沸点温度附近),调节合适pH,一般在0.25~5 h内可将溶液中铝全部脱除。此沉淀物易于过滤,脱除铬后可用于制造沸石或者高温氧化的催化剂等。

表1 不同焙烧工艺所得浸出液中各种成分及含量

Table 1 Composition of leaching liquor from different roasting processes

此方法简单可行,缺点是硅化合物的加入会增加溶液黏度,铝含量较高时,易导致铝硅酸盐的过滤速度变慢;同时控制沉淀条件在沸点附近,高浓度的铬酸盐溶液蒸发可能产生大量含铬水蒸汽,会造成环境污染。

2.1.2 氢氧化铝沉淀法

水解生成氢氧化铝沉淀法,主要原理是降低浸出液的pH值,促使铝酸钠发生水解作用析出氢氧化铝沉淀,经保温熟化彻底脱除铝。中和除铝的主要方式有:

1) 加入酸中和

(8)

(8)

2) 加入铬酸盐中和

(9)

(9)

3) 加入重铬酸盐中和

(10)

(10)

4) 通入二氧化碳除铝

(11)

(11)

直接采用加酸中和沉铝,铝泥颗粒细小,难以过滤,铬的带损也较高,逐渐被其他沉铝方式所代替。徐红彬等[42]通过计算在25 ℃时,混合溶液中[Al(Ⅲ)]和[H+]、 之间的对应关系,控制加压碳酸化反应的PH值为6.0左右,将溶液中Al(Ⅲ)以氢氧化铝形式全部脱除。为了克服在无钙或者添加少量含钙物质(氧化钙或者白云石等)焙烧条件下的铝泥难分离问题,在铁渣未过滤前,加入硫酸或者碱金属重铬酸盐调节pH值在6~9之间,使铝泥和铁渣一起沉淀,渣易于过滤[43]。此方法工艺简单、可操作性强,但是进入铁渣中的铝泥,不能有效地重新利用。

之间的对应关系,控制加压碳酸化反应的PH值为6.0左右,将溶液中Al(Ⅲ)以氢氧化铝形式全部脱除。为了克服在无钙或者添加少量含钙物质(氧化钙或者白云石等)焙烧条件下的铝泥难分离问题,在铁渣未过滤前,加入硫酸或者碱金属重铬酸盐调节pH值在6~9之间,使铝泥和铁渣一起沉淀,渣易于过滤[43]。此方法工艺简单、可操作性强,但是进入铁渣中的铝泥,不能有效地重新利用。

铬酸钠碱性液的pH值在10以上,溶液中的 主要以

主要以 形式存在[44],铝酸盐水解生成氢氧化铝有种分分解和碳酸化分解两种方式。美国联合化学公司[45](Allied Chemical Corporation)采用种分方式,以三水铝石作为晶种,在碱性液中缓慢的加入重铬酸钠进行中和,反应可生成三水铝石、拜耳铝石和一水软铝石的混合物,铝泥易于过滤,但是中和、保温熟化的时间长达9~12 h。

形式存在[44],铝酸盐水解生成氢氧化铝有种分分解和碳酸化分解两种方式。美国联合化学公司[45](Allied Chemical Corporation)采用种分方式,以三水铝石作为晶种,在碱性液中缓慢的加入重铬酸钠进行中和,反应可生成三水铝石、拜耳铝石和一水软铝石的混合物,铝泥易于过滤,但是中和、保温熟化的时间长达9~12 h。

相对于种分氢氧化铝,碳分法可在较短时间获得晶粒粗大,容易过滤的氢氧化铝[46]。因此,可在铬酸钠碱性液中通入二氧化碳,促使铝酸钠溶液分解得到氢氧化铝沉淀(公式(15))。

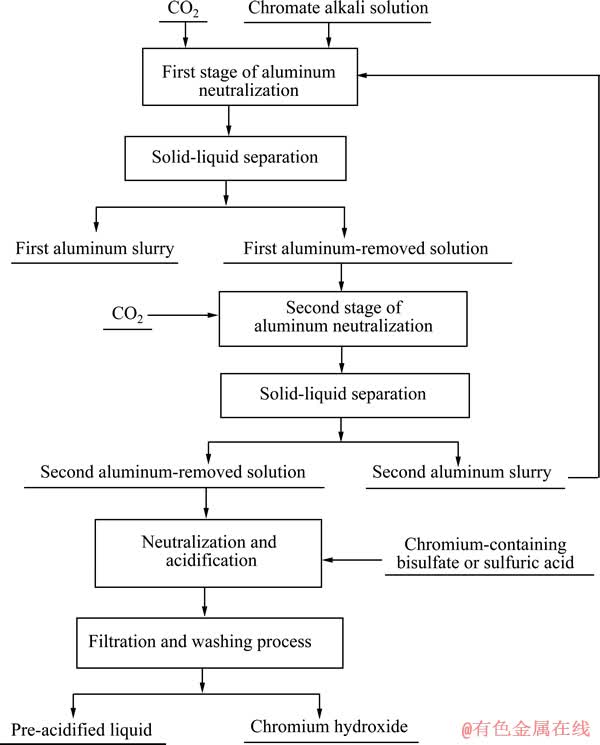

德国的SPECKETER[47]将铝矾土和铬铁矿与碱混合后焙烧,得到含有大量铝酸钠的浸出液。铬酸钠浸出液先经高压蒸煮脱除铝硅酸钠,然后在搅拌的同时引入二氧化碳,碳酸化分解、过滤、洗涤,制得纯度较高的氢氧化铝产品。滤液中的碳酸盐经过蒸发结晶,可返回用于铬铁矿焙烧,工艺流程示意图如图1所示。李先荣等[48]将铬酸钠碱性液碳化脱钒,得到钒酸镁沉淀。然后调节pH值,控制合适的碳化压力(0.01~5 MPa)、温度、保温时间等,使铝、硅、铁等杂质生成沉淀,得到杂质小于5×10-6的料液。李小斌等[49]采用碳酸化分解,经两段分解脱除杂质铝(图2),首先在碱性液中通入二氧化碳,第一段碳酸化分解;固液分离后,进行二段碳酸化分解,细颗粒氢氧化铝作为一段分解的晶种,产物氢氧化铝颗粒较大。

低碱体系中,硅化合物黏度较高,加入硅化合物脱铝适用于铝含量较低体系;水解氢氧化铝法工艺简单,易于操作。传统的酸中和法成本高,胶状铝泥的过滤性和铬带损难以解决;种分分解时间长;碳分分解时间短,颗粒粗大,铝泥含水仅23%~40%;铬带损降至(以NaCr2O7·2H2O计)0.05%~0.1%。有效地实现了铬铝分离,并有利于铝泥的综合回收利用。同时二氧化碳来源丰富,可利用工业窑气等,有利于降低成本,该技术已初步实现工业化生产。

2.2 氢氧化钾(钠)介质-高碱浓度脱除铝

2.2.1 加入钙化合物脱除铝

加入钙化合物可有效地脱除溶液中的铝杂质。同时得到的沉淀物颗粒较为粗大;易于过滤和洗涤;操作简单,成本也较为低廉。首先是钙与铝酸钠溶液反应生成铝酸三钙,然后有硅存在的条件下可能与硅结合形成水化石榴石。加入氧化钙或氢氧化钙主要反应方程式为

CaO+H2O Ca(OH)2 (12)

Ca(OH)2 (12)

(13)

(13)

以含碱(以K2O计)160 g/L液相氧化法浸出液为原料,添加氧化钙[38, 50]可除去溶液中的铝和硅。在KOH-K2CO3-Al2O3-H2O系统中,添加CaO,主要产物为3CaO·Al2O3·6H2O。系统中引入硅后,有铁渣存在时,脱铝硅产物为Ca3AlFe(SiO4)(OH)8;无铁渣存在时,生成固相Ca2.93Al1.97Si0.64O2.56(OH)9.44。控制条件溶液中Al2O3浓度可降至1.89 g/L以下。在50%的氢氧化钾浓度下,曲景奎等[51]进一步证实了氢氧化钙具有更好的脱铝效果。郭为等[52]添加钙预脱除硅和部分铝,证实3CaO×Al2O3×6H2O产物的存在,同时,硅存在时可生成水化石榴石3CaO×Al2O3×xSiO2×(6-2x)H2O。

图1 US1760788中除铝流程示意图

Fig. 1 Flow diagram of aluminum removal process in US1760788

图2 CN101723461A中两段脱铝流程示意图

Fig. 2 Flow diagram of two-stage aluminum removal process in CN101723461A

加入钙易于脱除铝,形成易过滤的产物。同时为保证脱除杂质反应的充分进行,必须添加过量的钙,文献中控制合适的CaO添加量为理论值的1.2倍[38]。沉淀物3CaO·Al2O3·6H2O部分分解,生成碳酸钙或微溶于水的氢氧化钙,可能会在溶液中引入钙杂质[50]。溶液中铝硅共存时,沉淀产物中w(Cr)<0.7%,铬带损相对较少,但是与低碱溶液水解得到的氢氧化铝相比较,铬含量仍然较高。

2.2.2 铝酸钠结晶-种分氢氧化铝

钾碱亚熔盐液相氧化法中,为避免杂质对铬酸钾分离效率的影响,实现体系中铬铝的分离,WANG等[53]计算了KOH-K2CrO4-KAlO2-H2O和NaOH- Na2CrO4-NaAlO2-H2O体系的相图,并测定了40 ℃和80 ℃时,K2CrO4和KAlO2在KOH中的溶解度。杜春华等[54-55]研究了K2O浓度低于50 g/L的条件下,KOH- K2CO3-K2CrO4-Al2O3-SiO2-H2O体系中铝酸钾、碳酸钾混合盐的结晶行为,证实在线性冷却条件下,搅拌速率160 r/min,晶种浓度1.12%,转速270 r/min,亚熔盐介质中Al的浓度可降至0.98%,亚熔盐介质的有效净化。

针对钠碱亚熔盐体系[56],高碱浓度下,邹兴等[57-58]将铬酸钠浸出液进行冷却,得到含NaOH、NaAlO2和Na2CrO4的粗晶,粗晶采用含铬酸钠溶液洗涤,得到较纯的铬酸钠晶体。洗涤液调节碱浓度在400~600 g/L之间,得到铝酸钠体;晶体溶解后,种分并陈化50 h以上,可获得氢氧化铝晶体,从而实现铬酸钠和铝酸钠的完全分离。李莉等[59]借鉴此工艺,在红土矿碱熔后得到的NaOH-NaAlO2-Na2CrO4-Na2CO3-H2O体系中,经结晶、纯化并溶解,采用二氧化碳强化种分结晶过程,可获得氢氧化铝产品。

2.2.3 萃取氢氧化钾-种分氢氧化铝

由于在钾碱亚熔盐液相氧化清洁生产工艺中,溶液中碱/铝摩尔比(n(K2O)/n(Al2O3))较高,直接采用种分方式很难使碱性液中氢氧化铝沉淀析出。而且,对于碱体系,碳分沉铝生成的大量碳酸盐还需要苛化,才可重新返回反应工序利用,增加了苛化工序的成本。因此,张盈等[39]和ZHANG等[60]研究了K2O-Al2O3- H2O-CH3OH体系中氢氧化钾的萃取热力学平衡。将体系中氢氧化钾进行萃取,降低溶液碱、铝的摩尔比,然后利用种分脱除铝。在此基础上,针对现场物料成分,采取非连续两级逆流萃取工艺,完成了百升级现场试验验证,结果表明:铝酸钾液经萃取分离氢氧化钾后,碱、铝的摩尔比可从3.43下降至1.9左右。然后,可利用种分分解脱除铝杂质,并得到产品氢氧化铝。

铝酸钠结晶-种分法和萃取氢氧化钾-种分法两种工艺主要用于高碱体系如亚熔盐液相氧化法的熟料浸出液。前者工艺流程较长,主要是冷却结晶过程,且种分时间长,能耗及成本相对较高。后者与萃取相结合,降低分子比,溶液可在较短时间内水解得到氢氧化铝沉淀;氢氧化钾经反萃后,返回亚熔盐浸出工序重新利用。若能进一步提高萃取剂的利用率,降低成本,应用于碱度较高的体系有很大的优势。

3 展望

进入21世纪以来,德国、日本、英国相继退出铬盐生产行业,美国也缩小铬盐的生产规模,中国已发展成为全球铬化合物产量最大的国家。铬盐行业的发展,促使铬盐企业不断的进行技术革新,企业开始拥有自主知识产权的新技术。铬盐工艺的进步,促使生产过程中除铝方法不断发展,同时,除铝方法还有一些问题需要进一步探讨。

1) 铬盐生产工艺与脱铝方法

铝的脱除方法的选择是建立在铬盐生产工艺基础上的。研究的重点是有效地降低固相除铝过程的能耗,并避免结窑。碳素铬铁-铬酸钠联合法,可在冶炼工序过程中使铝杂质进入渣中,但是能耗相对较高;有钙焙烧法可有效地降低进入液相中的可溶性铝的含量,但是有钙焙烧排放铬渣中含有致癌物质铬酸钙,难以处理。针对现有的工业化的工艺,无钙焙烧和液相氧化法排渣量小[8, 61],从经济指标和环境指标考虑,都拥有较大优势。同时,我国工信部在《铬盐行业清洁生产实施计划》中也指出,将在2013年底前淘汰有钙焙烧工艺,推广铬盐生产工艺包括无钙焙烧法和液相氧化法。

为避免窑炉结圈,提高碱利用率,无钙焙烧中少碱多步焙烧法和添加无钙填料的方法具有较大优势,但是焙烧工序能耗较高;液相氧化法能耗低,溶液碱和铝含量高,除铝工艺较为复杂。如果能进一步降低能耗,减少环境污染,将非常有利于铬盐的技术路线调整。

2) 铝相化合物的生成及综合利用

固相法除铝研究较多,渣中铝主要以铝硅酸钠和铝硅酸镁钠存在,部分铝固溶在镁铁矿晶格中,主要用于返渣焙烧,不能单独回收利用。对于铬盐熟料浸出液的脱铝方法,主要研究重点是从溶液中得到易于分离的铝相杂质;减少铬酸盐夹损,避免产品的二次污染。相对而言,利用碳酸化方式,获得氢氧化铝沉淀,易于实现产物的分离和铝泥的综合回收利用。同时,为更好地对铬酸钠浸出溶液中铝杂质进行脱除,许多问题还需要进一步研究,如晶种的粒度范围选择与产品中铬酸钠的夹带;大量铬酸钠的存在对铝酸盐水解生成Al(OH)3的动力学的影响;大量铬酸盐存在对铝酸盐的水解生成的氢氧化铝的晶型、晶粒生长的影响等。对水解过程进行详细研究,将有助于拓展铬盐副产品的应用,提高铬盐生产过程中的综合效益。

REFERENCES

[1] 纪 柱. 中国铬盐近五十年发展概况[J]. 无机盐工业, 2010, 42(12): 1-5.

JI Zhu. Development status of China’s chromium salts in recent 50 years[J]. Inorganic Chemicals Industry, 2010, 42(12): 1-5.

[2] 丁 翼. 中国铬盐生产状况与展望[J]. 化工进展, 2004, 23(4): 345-348.

DING Yi. Present status and prospect of chromate production in China[J]. Chemical Industry and Engineering Progress, 2004, 23(4): 345-348.

[3] 纪 柱. 开发实施中的中国铬酸钠新工艺(Ⅰ)[J]. 无机盐工业, 2010, 42(1): 1-4.

JI Zhu. New technologies for sodium chromate being developed and implemented in China(Ⅰ)[J]. Inorganic Chemicals Industry, 2010, 42(1): 1-4.

[4] 纪 柱. 铬铁矿无钙焙烧的反应机理[J]. 无机盐工业, 1997(1): 18-21.

JI Zhu. Reaction mechanism of chromite non-calcium roasting method[J]. Inorganic Chemicals Industry, 1997(1): 18-21.

[5] 张天平, 张天成. 热混无钙铬酸钠制备工艺: 中国, CN 101066779[P]. 2010-09-08.

ZHANG Tian-ping, ZHANG Tian-cheng. Lime free roasting method for producing sodium chromate using hot alkali: China, CN 101066779[P]. 2010-09-08.

[6] 李景冠, 张林进, 陈川辉, 叶旭初. 铬铁矿无钙焙烧过程中氧含量对氧化率的影响[J]. 无机盐工业, 2011, 43(10): 36-38.

LI Jing-guan, ZHANG Lin-jin, CHEN Chuan-hui, YE Xu-chu. Effect of oxygen content on oxidation ratio of chromium in lime free roasting process[J]. Inorganic Chemicals Industry, 2011, 43(10): 36-38.

[7] 李小斌, 齐天贵, 彭志宏, 刘桂华, 周秋生. 铬铁矿氧化焙烧动力学[J]. 中国有色金属学报, 2010, 20(9): 1822-1828.

LI Xiao-bin, QI Tian-gui, PENG Zhi-hong, LIU Gui-hua, ZHOU Qiu-sheng. Kinetics of chromite ore in oxidation roasting process[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1822-1828.

[8] ZHANG Y, LI Z H, QI T, ZHENG S L, LI H Q, XU H B. Green manufacturing process of chromium compounds[J]. Environmental Progress, 2005, 24(1): 44-50.

[9] ZHENG S L, ZHANG Y, LI Z H, QI T, LI H Q, XU H B. Green metallurgical processing of chromite[J]. Hydrometallurgy, 2006, 82(3/4): 157-163.

[10] XU H B, ZHANG Y, LI Z H, ZHENG S L, WANG Z K, QI T, LI H Q. Development of a new cleaner production process for producing chromic oxide from chromite ore[J]. Journal of Cleaner Production, 2006, 14(2): 211-219.

[11] ARSLAN C, ORHAN G. Investigation of chrome (Ⅵ) oxide production from chromite concentrate by alkali fusion[J]. International Journal of Mineral Processing, 1997, 50(1/2): 87-96.

[12] 彭忠东. 胡国华. 一种由碳素铬铁碱性焙烧制取铬酸盐的方法: 中国, CN 102040245A[P]. 2011-05-04.

PENG Zhong-dong, HU Guo-hua. Alkali roasting method for production of chromate using carbon ferrochrome: China, CN 102040245A[P]. 2011-05-04.

[13] 董 达, 关振波, 刘 顺, 孙久赫, 柳宏伟, 戈宝武. 一种焙烧湿法-火法联产生产铬盐、铬铁合金的方法: 中国, CN 101709369A[P]. 2010-05-19.

DONG Da, GUAN Zhen-bo, LIU Shun, SUN Jiu-he, LIU Hong-wei, GE Bao-wu. Hydrometallurgy-pyrometallurgy method for production of chromate and ferrochrome alloys: China, CN 101709369A[P]. 2010-05-19.

[14] 张志理, 马贵宦, 韩惠田. 一种铬酸钠的制造方法: 中国, CN 1181353[P]. 2000-09-22.

ZHANG Zhi-li, MA Gui-huan, HAN Gui-tian. Method for production of sodium chromates: China, CN 1181353[P]. 2000-09-22.

[15] 丁 翼, 纪 柱. 铬化合物生产与应用[M]. 北京: 化学工业出版社, 2003: 48-55.

DING Yi, JI Zhu. Production and application of chromium compounds[M]. Beijing: Chemical Industry Press, 2003: 48-55.

[16] 黄焯枢, 王康海, 杨昌林, 杨 智. 制备铬酸钠熟料的方法: 中国, CN 1153142[P]. 2000-02-02.

HUANG Chao-shu, WANG Kang-hai, YANG Chang-lin, YANG Zhi. Method for production of sodium chromates: China, CN 1153142[P]. 2000-02-02.

[17] 王志义, 李玉锁. 铬铁矿少钙焙烧的工业应用[J]. 铁合金, 2000, 31(3): 27-30.

WANG Zhi-yi, LI Yu-suo. Commercial application of chromite roasting with few calcic additives[J]. Ferroalloys, 2000, 31(3): 27-30.

[18]  H, FLITTARD C. Alkali treatment of chromium ores: United States, US 3510256[P]. 1970-05-05.

H, FLITTARD C. Alkali treatment of chromium ores: United States, US 3510256[P]. 1970-05-05.

[19] 袁代建, 张金聪, 李小利, 刘清华. 铬铁矿两段焙烧法: 中国, CN102275992A[P]. 2011-12-14.

YUAN Dai-jian, ZHANG Jin-cong, LI Xiao-li, LIU Qing-hua. Two stage roasting method of chromite ore: China, CN 102275992A[P]. 2011-12-14.

[20] 董 达, 关振波, 刘 顺, 杨 海, 郭新亮, 柳宏伟. 铬矿少碱焙烧生产铬酸钠的方法: 中国, CN 101717119A[P]. 2012-06-06.

DONG Da, GUAN Zhen-bo, LIU shun, YANG Hai, GUO Xin-liang, LIU Hong-wei. Manufacture of sodium chromate: China, CN 101717119A[P]. 2012-06-06.

[21] 韩登仑, 张忠元, 李元魁, 杨 海, 何喜善, 邓珍兰, 张红军, 杨昆山. 无钙焙烧生产铬酸钠工艺: 中国, CN 1579947[P]. 2005-02-16.

HAN Deng-lun, ZHANG Zhong-yuan, LI Yuan-kui, YANG Hai, HE Xi-shan, DENG Zhen-lan, ZHANG Hong-jun, YANG Kun-shan. Lime-free roasting method for production of sodium chromates: China, CN 1579947[P]. 2005-02-16.

[22] 韩登仑, 张忠元, 张天仁, 张宏军. 由铬铁矿经无钙焙烧生产铬酸钠的方法: 中国, CN 100462308C[P]. 2009-02-18.

HAN Deng-lun, ZHANG Zhong-yuan, ZHANG Tian-ren, ZHANG Hong-jun. Non-calcium roasting chromite to produce sodium chromate: China, CN 100462308C[P]. 2009-02-18.

[23] 杨振祥. 铬铁矿制备铬酸钠的焙烧方法: 中国, CN 1218879C[P]. 2005-09-14.

YANG Zhen-xiang. Roasting method for production of sodium chromate: China, CN 1218879C[P]. 2005-09-14.

[24] HANS N, MEUSSDOERFFER J N, HAS-GEORG N V, BOCKEHNANN W. Disintegration of silica-rich chromite: United States, US 4112046[P]. 1978-12-05.

[25] MEUSSDOERFFER J N, HANS N, HAS-GEORG N V, BOCKEHNANN W. Disintegration of chromites: United States, US 4500350[P]. 1985-02-19.

[26] 朱德庆, 熊守安, 仉宏亮, 潘 建. 铬铁精矿球团烧结工艺与机理[J]. 中南大学学报: 自然科学版, 2010, 41(5): 1658-1667.

ZHU De-qing, XIONG Shou-an, ZHANG Hong-liang, PAN Jian. Pellets sintering process of chromite concentrate and mechanism of consolidation[J]. Journal of Central South University: Science and Technology, 2010, 41(5): 1658-1667.

[27] DWARAPUDI B S, RAO S M. Method to improve properties of green and fired chromite pellets by using alkaline compound: India, IN 200701157[P]. 2010-04-30.

[28] KORLYKHANOV A A, NIZOV V A. Alkali metal chromate production comprises oxidizing burning of chromites by preliminary granulation of two-component mixtures with initiating additives: Russia, RU 2349552C[P]. 2009-03-20.

[29] SHALABI M E H, EL-HUSSINY N A, EL-AFIFI S Y, EL-EBIARY N N, ZAHER F M S. Kinetics of formation of sodium chromate from El-Baramiya chromite ore concentrate with soda ash pellets[C]//OZBAYOGLU G, HOSTEN C, ATALAY M U, HICYILMAZ C, AROL A I. Mineral Processing on the Verge of the 21st Century. Schipholweg, Netherlands: A A Balkema Publishers, 2000: 549-552.

[30] 张登亮, 宋 锋, 石硕年, 梅海军. 无钙造粒焙烧加工铬铁矿工艺方法: 中国, CN 85102681[P]. 1998-12-09.

ZHANG Deng-liang, SONG Feng, SHI Shuo-nian, MEI Hai-jun. Lime free roasting of chromites balls method for production of chromates: China, CN 85102681[P]. 1998-12-09.

[31] 梅海军, 王劲松, 宋卫国, 尹新建, 杨永飚, 王爱山, 张 忠. 铬酸盐的高效、节能、清洁的制造方法: 中国, CN 101508466[P]. 2011-03-23.

MEI Hai-jun, WANG Jin-song, SONG Wei-guo, YIN Xin-jian, YANG Yong-biao, WANG Ai-shan, ZHANG Zhong. Efficient, green and low cost method for production of chromates: China, CN 101508466[P]. 2011-03-23.

[32] 纪 柱. 碳素铬铁水热法制红矾钠[J]. 无机盐工业, 2012, 44(2): 44-47.

JI Zhu. Preparation of sodium bichromate dihydrate by hydrothermal oxidizing reaction[J]. Inorganic Chemicals Industry, 2012, 44(2): 44-47.

[33] 胡国华. 一种从碳素铬铁中生产三氧化二铬和草酸亚铁的方法: 中国, CN 101041466[P]. 2007-09-26.

HU Guo-hua. Method for production of chromium oxide and ferrous oxalate using carbon ferrochrome: China, CN 101041466[P]. 2007-09-26.

[34] 胡国荣, 王亲猛, 彭忠东, 杜 柯, 王 飞, 蒋庆来. 高碳铬铁制备氢氧化铬的研究[J]. 无机盐工业, 2010, 42(11): 30-32.

HU Guo-rong, WANG Qin-meng, PENG Zhong-dong, DU Ke, WANG Fei, JIANG Qing-lai. Research on preparation of chromium hydroxide from high-carbon ferrochrome[J]. Inorganic Chemicals Industry, 2010, 42(11): 30-32.

[35] 王 飞. 以高碳铬铁合金粉为原料制备三氧化二铬[D]. 长沙: 中南大学, 2009: 18-22.

WANG Fei. Chromium oxide was produced from high-carbon ferrochrome alloy powder[D]. Changsha: Central South University, 2009: 18-22.

[36] 郑诗礼, 张 洋, 徐红彬, 肖清贵, 张 懿. 一种铬铁矿液相氧化生产铬酸钠的清洁生产方法: 中国, CN 102001708A[P]. 2011-04-06.

ZHENG Shi-li, ZHANG Yang, XU Hong-bin, XIAO Qing-gui, ZHANG Yi. Green method for production of chromates by liquid oxidative reactions from chromites: China, CN 102001708A[P]. 2011-04-06.

[37] 徐红彬, 石义朗, 张 懿, 蔡再华, 李佐虎, 程西川, 张小飞, 陈小红, 张 洋, 刘静文. 一种铬铁矿加压浸出清洁生产铬酸钠的方法: 中国, CN 101817561[P]. 2012-05-30.

XU Hong-bin, SHI Yi-lang, ZHANG Yi, CAI Zai-hua, LI Zuo-hu, CHENG Xi-chuan, ZHANG Xiao-fei, CHEN Xiao-hong, ZHANG Yang, LIU Jing-wen. High pressure leaching method for production of chromates from chromites: China, CN 101817561[P]. 2012-05-30.

[38] 王少娜, 郑诗礼, 张 懿. 铬盐清洁生产工艺中铝硅的脱除[J]. 中国有色金属学报, 2007, 17(7): 1188-1194.

WANG Shao-na, ZHENG Shi-li, ZHANG Yi. Separation of aluminum and silicon in clean production process for potassium dichromate[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1188-1194.

[39] 张 盈, 郑诗礼, 王晓辉, 张 懿. 钾碱体系中碱铝高效萃取分离研究与应用[C]// 中国有色金属学会第八届学术年会论文集. 北京: 中国有色金属学会, 2010: 156-161.

ZHANG Ying, ZHENG Shi-li, WANG Xiao-hui, ZHANG Yi. The study and application of extraction separation of potassium and aluminum in potash solutions[C]// The 8th Council Symposium the Nonferrous Metals Society of China. Beijing: The Nonferrous Metals Society of China, 2010: 156-161.

[40] 刘长河. 铬铁矿氧化焙烧工艺的判定和评价[J]. 无机盐工业, 2012, 44(3): 44-46.

LIU Chang-he. Determination and evaluation on oxidizing-roasting process of chromite[J]. Inorganic Chemicals Industry, 2012, 44(3): 44-46.

[41] HOLTZ W J. Process for removal of alumina from aqueous alkali metal chromate solutions: United States, US 4173618[P]. 1979-09-06.

[42] 徐红彬, 张 懿, 李佐虎, 李会泉. 铬盐清洁生产工艺中铝的脱除[J]. 化工进展, 2003, 22(1): 46-48.

XU Hong-bin, ZHANG Yi, LI Zuo-hu, LI Hui-quan. Separation of aluminum(Ⅲ) in the clean production process for potassium dichromate[J]. Chemical Industry and Engineering Progress, 2003, 22(1): 46-48.

[43] ZAHN, GMBH. Process for preparing alkali metal chromate solutions: Great Britain, GB 1057678[P]. 1963-10-02.

[44] PANIAS D, KRESTOU A. Effect of synthesis parameters on precipitation of nanocrystalline boehmite from aluminate solutions[J]. Powder Technology, 2007, 175(3): 163-173.

[45] DOUGLAS G F, THOMAS R M, TERRY L S. Alumina removal from chromate leach liquors: Unites States, US 3899568[P]. 1975-08-12.

[46] WANG Z, BI S W, YANG Y H, YUAN Z F. Evolution of particle size and strength of hydrargillite from carbonization in seeded sodium aluminate liquors[J]. Journal of Crystal Growth, 2005, 274(1/2): 218-225.

[47] SPECKETER H, HENSCHEL G. Production of chromates with simultaneous recovery of alumina: Unites States, US 1760788[P]. 1930-05-27.

[48] 李先荣, 张国庆, 马顺友, 陈 宁, 秦 龙. 一种铬酸钠碱性液的除杂方法: 中国, CN 101693555A[P]. 2010-04-14.

LI Xian-rong, ZHANG Guo-qing, MA Shun-You, CHEN Ning, QIN Long. Separation of impurities from caustic sodium chromate solution: China, CN 101693555A[P]. 2010-04-14.

[49] 李小斌, 齐天贵, 彭志宏, 刘桂华, 周秋生. 一种铬酸钠碱性液中和除铝方法: 中国, CN 101723461A[P]. 2010-06-09.

LI Xiao-bin, QI Tian-gui, PENG Zhi-hong, LIU Gui-hua, ZHOU Qiu-sheng. Neutralization and separation of aluminum from caustic sodium chromate solution: China, CN 101723461A[P]. 2010-06-09.

[50] WANG S N, ZHENG S L, ZHANG Y. Stability of 3CaO·Al2O3·6H2O in KOH+K2CO3+H2O system for chromate production[J]. Hydrometallurgy, 2008, 90(2/4): 201-206.

[51] 曲景奎, 郑诗礼, 徐红彬, 齐 涛, 张 懿. 铬铁矿液相氧化产物的杂质分离及钾碱循环[J]. 湿法冶金, 2007, 26(4): 193-197.

QU Jing-kui, ZHENG Shi-li, XU Hong-bin, QI Tao, ZHANG Yi. Separation of impurities from liquid phase oxidation product of chromite and recycle of caustic potash solution[J]. Hydrometallurgy of China, 2007, 26(4): 193-197.

[52] 郭 为, 余志辉, 王京刚, 曲景奎, 齐 涛, 韩晓英. 铬酸钠溶液中微量铝硅杂质的脱除[J]. 过程工程学报, 2011, 11(4): 590-594.

GUO Wei, YU Zhi-hui, WANG Jing-gang, QU Jing-kui, QI Tao, HAN Xiao-ying. Removal of trace al and Si impurities in sodium chromate solution[J]. The Chinese Journal of Process Engineering, 2011, 11(4): 590-594.

[53] WANG X D, CUI J L, GE X L, ZHENG S L, ZHANG M, ZHANG Y. Thermo-dynamic study of K2CrO4-KAlO2-KOH- H2O and Na2CrO4-NaAlO2-NaOH-H2O systems[J]. International Journal of Minerals, Metallurgy and Materials, 2004, 11(6): 500-504.

[54] 杜春华, 张 懿, 郑诗礼, 洪 涛. 铬酸钾-碳酸钾高效分离研究 Ⅰ. 相图分析与溶解度计算[J]. 化工科技, 2007, 15(5): 1-5.

DU Chun-hua, ZHANG Yi, ZHENG Shi-li, HONG Tao. Study on the effective separation of potassium chromate and potassium carbonate Ⅰ. Phase diagram analysis and solubility calculation[J]. Science & Technology Chemical Industry, 2007, 15(5): 1-5.

[55] 杜春华, 张 懿, 郑诗礼, 洪 涛. 铬酸钾-碳酸钾高效分离研究Ⅱ. 结晶工艺实验研究[J]. 化工科技, 2007, 15(6): 5-8.

DU Chun-hua, ZHANG Yi, ZHENG Shi-li, HONG Tao. Study on the effective separation of potassium chromate and potassium carbonate Ⅱ. Experimental investigation on the crystallization process[J]. Science & Technology Chemical Industry, 2007, 15(6): 5-8.

[56] 郑诗礼, 张 懿. 铬铁矿熔盐液相氧化新反应系统的热力学分析[J]. 中国有色金属学报, 1999, 9(4): 800-804.

ZHENG Shi-li, ZHANG Yi. Thermodynamic analysis on new reaction system oxidation of chromite in molten salt[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 800-804.

[57] 邹 兴, 张 懿, 李佐虎, 韩其勇. NaOH-NaAlO2- Na2CrO4-H2O四元水盐体系相平衡[J]. 化工冶金, 1998, 19(2): 118-121.

ZOU Xing, ZHANG Yi, LI Zuo-hu, HAN Qi-yong. Phase equilibra of NaOH-NaAlO2-Na2CrO4-H2O saline system[J]. Engineering Chemistry & Metallurgy, 1998, 19(2): 118-121.

[58] 张 懿, 李佐虎, 王志宽, 徐 霞, 刘嘉澍, 齐 涛, 邹 兴. 铬酸钠的清洁生产方法: 中国, CN 1062528C[P]. 2001-02-28.

ZHANG Yi, LI Zuo-hu, WANG Zhi-kuan, XU Xia, LIU Jia-shu, QI Tao, ZOU Xing. Cleaner method for production of chromates: China, CN 1062528C[P]. 2001-02-28.

[59] 李 莉, 曲景奎, 齐 涛, 王京刚, 李 洁. 熔盐法活化处理含铬红土镍矿浸出液的铬铝分离及碱液循环[J]. 过程工程学报, 2010, 10(4): 667-672.

LI Li, QU Jing-kui, QI Tao, WANG Jing-gang, LI Jie. Separation of chromium and aluminum alkali recirculation in treatment of laterite nickel ore containing chromium with NaOH solution[J]. The Chinese Journal of Process Engineering, 2010, 10(4): 667-672.

[60] ZHANG Y, ZHENG S L, DU H, WANG S N and ZHANG Y. Solubility of Al2O3 in the Na2O-Al2O3-H2O-CH3OH system at (30 and 60) ℃[J]. Journal of Chemical Engineering Data, 2010, 55(3): 1237-1240.

[61] 梅海军, 李 霞, 张大威, 马光辉, 韩登仑, 张忠元. 浅析铬盐清洁生产技术“无钙焙烧法”的优势[J]. 无机盐工业, 2005, 37(3): 5-13.

MEI Hai-jun, LI Xia, ZHANG Da-wei, MA Guang-hui, HAN Deng-lun, ZHANG Zhong-yuan. The advantages of cleaning production technology “non-calcium roasting method” for chromium salt[J]. Inorganic Chemicals Industry, 2005, 37(3): 5-13.

(编辑 李艳红)

基金项目:国家杰出青年科学基金资助项目(51125018 );国家“十二五”科技支撑计划课题(2011BAC06B07);国家高技术研究发展计划资助项目(2011AA060704)

收稿日期:2012-08-18;修订日期:2012-02-20

通信作者:齐 涛,研究员,博士;电话/传真:010-62631710;E-mail: tqgreen@home.ipe.ac.cn