Trans. Nonferrous Met. Soc. China 22(2012) 2512-2516

Damping capacity of BaTiO3/Al composites fabricated by hot extrusion

FAN Gen-lian, LI Zhi-qiang, ZHANG Di

State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China

Received 9 July 2012; accepted 2 August 2012

Abstract: To develop new type of high damping metal matrix composites, large grain size barium titanate (BaTiO3) ceramic was sintered and added into Al powder to fabricate BaTiO3/Al composites through the powder metallurgy method and hot extrusion. The damping properties of BaTiO3 ceramic, Al matrix and BaTiO3/Al composites were examined by dynamic mechanical analysis in the temperature range from 273 K to 573 K. The results show that although BaTiO3 exhibits high damping (tan δ=0.12) below 400 K, the damping capacity of 10%BaTiO3/Al (mass fraction) composites below 400 K is not increased as compared to the Al matrix. On the other hand, the damping capacity above 450 K is greatly enhanced due to the motion of dislocations at the interfaces between ceramic particles and Al matrix. The failure of exerting the intrinsic damping of BaTiO3 particles in the composites is attributed to the poor interface bonding between the particles and the matrix. The tensile strength of the composite is 42% higher than that of the Al matrix, which indicates the possibility of obtaining high strength and high damping composites via interface improvement and the addition of high volume fraction of large grain BaTiO3 particles.

Key words: high damping materials; metal matrix composites; barium titanate; mechanical properties; interface

1 Introduction

Material’s damping capacity is the ability to dissipate vibration energy through the internal motion of various defects under stress [1]. With the increasing need for high speed and high precision devices, the developing of high damping materials becomes more and more important in the modern world, in order to suppress noises, and to avoid vibrations in transportation vehicles and precision machines, etc [2-4].

Aluminum alloys and composites are one of the most important and widely used engineering materials. Due to their low density, the damping capacity becomes an essential parameter that should be considered during applications. Reinforcing Al with high performance particles, such as Al2O3, SiC, can greatly increase its strength and stiffness. But the damping capacity of these composites is not satisfying. Since the reinforcements are stiff and low damping, the damping capacity of composites mainly comes from the interface damping, which usually occurs at above 450 K. The damping capacity of composites between room temperature and 450 K is usually very low, even lower than that of the matrix due to the strengthening of the matrix [5-7]. Some researchers tried to reinforce Al with the graphite, which is soft and has high intrinsic damping capacity. The damping capacity of graphite reinforced composites did increase efficiently [8], however, the mechanical strength and stiffness were largely reduced. Thus, searching for a new kind of reinforcement that could increase both the damping capacity and mechanical properties is key issue in developing high damping metal matrix composites.

Some piezoelectric crystals, such as PZT [Pb(Zr0.52Ti0.48)O3] and barium titanate (BaTiO3), have been considered new kinds of reinforcements for developing high damping composites and have attracted attention in recent years [9-13]. YOSHIDA et al [10] demonstrated the possibility of increasing damping capacity by reinforcing PZT into Cu matrix. They also proved that BaTiO3 has better damping capacity than PZT. The damping capacity of BaTiO3 ceramic can reach more than 0.1, about 5 times higher than that of Al alloys, while the elastic modulus is about 15 times higher than that of Al [9,14]. Therefore, reinforcing Al with BaTiO3 particles could be an efficient way to get Al-based composites with both high strength and high damping capacity. In the present study, the feasibility of fabricating BaTiO3/Al composite by hot extrusion is firstly examined and the damping capacity and mechanical properties of the composites are evaluated.

2 Experimental

The fabrication of BaTiO3/Al composite samples involved three steps. Firstly, BaTiO3 raw powder (purity of 99.5%) was first cold pressed into disc plates (diameter of 20 mm) and sintered at 1673 K for 10 h in order to get large grain size ceramic plates. Secondly, the ceramic plates were broken into small pieces and mixed with Al powder (average diameter of 45 μm) in a planetary miller at a speed of 200 r/min for 0.5 h. Finally, the mixture was cold pressed into rods and hot extruded at 693 K under an extrusion ratio of 25:1. For a comparison, Al matrix sample was made by the same method.

The grain size of high temperature sintered BaTiO3 ceramic was observed with a VHX-1000E digital microscope. X-ray diffraction (XRD) was conducted to check the phase of BaTiO3 in the composites by using a Rigaku D/max-2550 instrument (Cu Kα). The fracture surfaces of the composites were analyzed by scanning electron microscope (SEM, FEI Quanta FEG 250) at 20 kV. To evaluate the tensile strength, the extruded rods were machined into pieces with 5 mm in diameter in accordance with ICS 59.100.01. The tensile strength was measured by a universal testing machine at an initial strain rate of 5×10-4 s-1 at room temperature (AUTOGRAPH AG-I 50 kN, Shimadzu Co. Ltd., Japan). Dynamic mechanical analysis (DMA Q800, TA Instruments) was used to characterize the damping capacity of different samples. BaTiO3 ceramic plate with the size of 15 mm×2 mm×0.8 mm was tested in three- point bending mode under a small alternating force (force amplitude: 1 N) when the temperature was changed continuously with cooling rate of 3 K/min. The BaTiO3/Al and Al matrix samples were tested in single cantilever mode at the constrained vibration amplitude of 30 μm. The testing frequency was in the range from 0.2 to 20 Hz.

3 Results and discussion

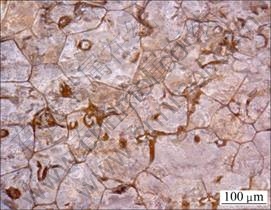

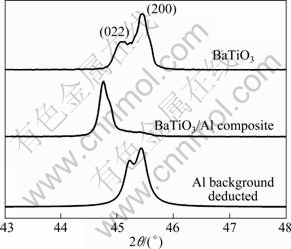

Figure 1 shows the optical microstructure of BaTiO3 ceramic after sintering at 1673 K for 10 h. High density BaTiO3 ceramics with large grain size have been obtained. The grain size of BaTiO3 is estimated to be 50-100 μm. Figure 2 shows the XRD patterns for the BaTiO3 ceramic and 10%BaTiO3/Al composite (mass fraction) tested at room temperature. The intensity ratio of peak (002) to peak (200) is 1:2 for BaTiO3 sample, which indicates that the BaTiO3 is in tetragonal phase at room temperature [11,15]. For the composite sample, the peaks for Al (200) and BaTiO3 are overlapped at around 45°. To confirm the state of BaTiO3 phase in the composite, the Al (200) peak is subtracted as a background peak. After deducting Al (200) peak, the intensity ratio of peak (002) to peak (200) is close to 1:2. This proves that the crystal structure of BaTiO3 is not destroyed during the composite preparation process. The fracture surface of the composite sample is shown in Fig. 3(a). Most BaTiO3 particles in the final composite are 1-2 μm, uniformly distributed in Al matrix. Some large particles with the size of 10 μm can also be found. From the magnified image in Fig. 3(b), it can be seen that the edge of these large BaTiO3 particles is broken to some degree and some small particles can be found between the large particle and matrix. The dimples in Al matrix indicate it is ductile fracture of Al matrix.

Fig. 1 Optical microstructure of BaTiO3 ceramic after sintering at 1673 K for 10 h

Fig. 2 XRD profiles of BaTiO3 ceramic and 10%BaTiO3/Al composites

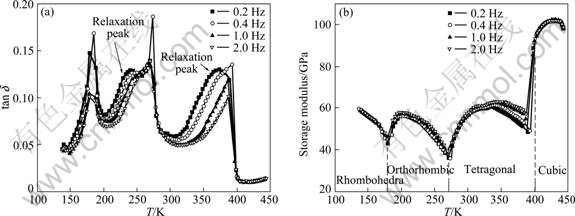

The damping capacity (tan δ) and storage modulus of BaTiO3 ceramic sample sintered at 1673 K for 10 h are shown in Fig. 4. Cooling from 450 K, three transitions from cubic to tetragonal, then to orthorhombic, and finally to rhombohedra phase can be clearly seen from the sudden increase of tan δ and the corresponding sharp modulus dip at peak temperatures [14,15]. Right below each transition temperature, broad and frequency dependent peaks (as indicated by arrows) can be found in tetragonal phase and orthorhombic phase. These relaxation-type damping peaks are usually attributed to the interaction between oxygen vacancies and domain walls [14,16,17], since they occur right below the ferroelectric phase transition temperatures, in which high density domain walls are formed in the material. These domain walls can move under external stress or electric fields [18]. The motion of domain walls and its interaction with point defect (oxygen vacancies) result in energy dissipation. According to the above damping mechanism, BaTiO3 with large grain size should have better damping capacity since the domain walls can move more easily in large grain size samples. From the tan δ curve in Fig. 4, we can see tan δ value of BaTiO3 ceramic sample is higher than 0.05 in the whole temperature below 400 K, 5 times higher than that of Al matrix. Thus, using BaTiO3 particles as reinforcement of Al matrix shall be expected to improve the damping capacity at temperatures below 400 K.

Fig. 3 Morphologies of fracture surfaces of 10%BaTiO3/Al composites

Fig. 4 Damping capacity (tan δ) and storage modulus as function of temperature during cooling (3 K/min) test by DMA for BaTiO3 ceramic sample sintered at 1673 K for 10 h

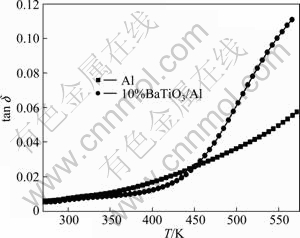

Figure 5 shows the damping capacity (tan δ) and storage modulus of 10%BaTiO3/Al composite sample. The tan δ value increases gradually from 273 K to 400 K, and no obvious peaks or steps can be detected at phase transition temperature. While above 400 K, the damping value increases quickly with the temperature rising and the test frequency decreasing. This is a typical damping curve that is usually observed in stiff particle reinforced composites, e.g. SiC/Al composite [5]. The failure of observing damping trace of BaTiO3 ceramic particles in the composites is probably due to the insufficient BaTiO3 content (volume fraction of 4.7%), and more likely to the poor interface bonding, since the applied stress can not be effectively transferred to ceramic particles without strong interface. Therefore, the domain wall motion in ceramic particles cannot be triggered, resulting in very low damping below 400 K. In the temperature range of 350-450 K, the damping value of 10%BaTiO3/Al composite is even lower than that of the Al matrix, as seen from the comparison in Fig. 6. While above 450 K, the damping capacity is higher than that of the matrix, due to the increased density of dislocations in the composites [6], mostly from the mismatch of coefficient of thermal expansion (CTE) between BaTiO3 (16×10-6 K-1) and Al matrix (23×10-6 K-1).

Fig. 5 Damping capacity (tan δ) and storage modulus as function of temperature during heating (3 K/min) test by DMA for 10%BaTiO3/Al composite extruded at 693 K

Fig. 6 Damping capacity of Al matrix and 10%BaTiO3/Al composite measured by DMA at vibration amplitude of 30 μm and frequency of 1 Hz

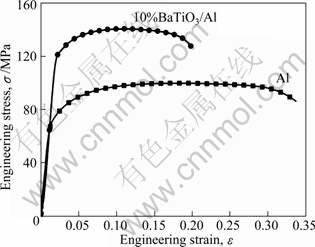

The tensile test result for 10%BaTiO3/Al composite and Al matrix is shown in Fig. 7. It can be seen that with the addition of 10%BaTiO3, the tensile strength increases to 140.5 MPa, about 42% higher than that of Al matrix (only 99 MPa). The yield stress also increases from 70 to 120 MPa. Although the elongation at break of the composite is only half of the matrix, it is still far beyond the requirement for engineering applications (5%).

Fig. 7 Tensile properties of Al matrix and 10%BaTiO3/Al composite

From the above primary experiment result, it can be seen that the BaTiO3 particles are good reinforcements for Al matrix. To fully exert their damping capacity, two aspects should be considered. Firstly, the interface bonding should be improved. ASARE [11] tried to coat a thin Cu film on the surface of BaTiO3 particles in their BaTiO3/Cu composites, and found that the porosity in the copper-coated Cu- BaTiO3 composite was less than that of the composites with uncoated particles. Thus, it will be encouraging to coat a suitable material on the surface of BaTiO3 to improve the interface bonding with Al in the future studies. Secondly, higher volume fraction of BaTiO3 is favorable for the purpose of achieving high damping. However, high volume fraction may result in poor ductility of the composite. One compromised method is to use larger size particles. The strengthening effect of large size particles may be not as good as the small ones, but for the composites with difficulty in interface matching, large size particles could be an optimized choice. Future studies shall be carried out along this direction.

4 Conclusions

1) BaTiO3 ceramic with large grain size exhibits high damping capacity below the Curie temperature, due to the motion of domain walls or the domain wall-point defect interaction.

2) Reinforcing Al with BaTiO3 ceramic by powder metallurgy and hot extrusion route can increase the tensile strength effectively. The tensile strength of the 10%BaTiO3/Al composite is 42% higher than that of the Al matrix.

3) The damping capacity of the 10%BaTiO3/Al composite fabricated by hot extrusion is not obviously increased below 450 K due to the poor interface bonding between BaTiO3 particle and the matrix, while above 450 K the damping capacity is higher than that of the matrix, owing to the increased density of dislocations in the composites.

4) To bring the high damping capacity of BaTiO3 into the composites, future studies should put effort to improve the interface bonding and the fabrication of composites with higher volume fraction of BaTiO3.

References

[1] BATIST R D. High damping materials: Mechanisms and applications [J]. Journal de Physique, 1983, 44 (C9): C9-39.

[2] YIN F X. Damping behavior and relevant physical mechanisms of high damping alloys [J]. Recent Res Devel Mat Sci, 2003, 4: 213-233.

[3] RAO S S. Mechanical vibrations [M]. New York: Addison-Wesley Publishing Company, 2000:1-50.

[4] ZHAO J X. Developing of military functional materials [J]. Journal of Materials Engineering, 1995, 3: 3-11. (in Chinese)

[5] KANG C S, MAEDA K, WANG K J, WAKASHIMA K. Dynamic Young's modulus and internal friction in particulate SiC/Al composites [J]. Acta Materialia, 1998, 46(4): 1209-1220.

[6] ZHANG X N, WU R J, LI X C, GUO Z X. Research on the interface damping in metal matrix composites [J]. Science in China: Series E, 2002, 32 (1): 14-17. (in Chinese)

[7] GU J H, ZHANG X Z, GU M Y. Effect of interphase on the damping capacity of particulate-reinforced metal matrix composites [J]. Journal of Alloys and Compounds, 2004, 381(1-2): 182-187.

[8] PEREZ R J, ZHANG J, GUNGOR M N, LAVERNIA E J. Damping behavior of 6061Al/Gr metal matrix composites [J]. Metallurgical Transactions A, 1993, 24(3): 701-712.

[9] FANTOZZI G, BOURIM E M, KAZEMI S. High damping in ferroelectric and ferrimagnetic ceramics [J]. Key Engineering Materials, 2006, 319: 157-165.

[10] YOSHIDA I, YOKOSUKA M, MONMA D, ONO T, SAKURAI M. Damping properties of metal–piezoelectric composites [J]. Journal of Alloys and Compounds, 2003, 355: 136-141.

[11] ASARE T A. Fabrication and damping behavior of particle BaTiO3 ceramic reinforced copper matrix composite [D]. Blacksburg: Virginia Polytechnic Institute and State University, 2004: 1-81.

[12] POQUETTE B. Damping behavior in ferroelectric reinforced metal matrix composites [D]. Blacksburg: Virginia Polytechnic Institute and State University, 2005: 1-121.

[13] GE Z H. Study on preparation and property of piezoelectric ceramic/metal matrix composites [D]. Harbin: Harbin Institute of Technology, 2007: 1-67. (in Chinese)

[14] CHEN L, XIONG X M, MENG H, LV P, ZHANG J X. Migration and redistribution of oxygen vacancy in barium titanate ceramics [J]. Applied Physics Letters, 2006, 89(7): 071916.

[15] HIPPEL A V. Ferroelectricity, domain structure, and phase transitions of barium titanate [J]. Reviews of Modern Physics, 1950, 22, 221-237.

[16] CHENG B L, GABBAY M, MAGLIONE M, FANTOZZI G. Relaxation motion and possible memory of domain structures in barium titanate ceramics studied by mechanical and dielectric losses [J]. Journal of Electroceramics, 2003, 10: 5-18.

[17] CHENG B L, GABBAY M, FANTOZZI G. Effect of oxygen vacancies on the motion of domain walls in BaTiO3 ceramics [J]. Defects and Diffusion in Ceramics: An Annual Retrospective IV, 2002, 206-207: 143-146.

[18] ZHANG L X, REN X. In situ observation of reversible domain switching in aged Mn-doped BaTiO3 single crystals [J]. Physical Review B, 2005, 71(17): 174108.

热挤压制备BaTiO3/Al复合材料的阻尼性能

范根莲,李志强,张 荻

上海交通大学 金属基复合材料国家重点实验室,上海 200240

摘 要:为了开发新型高阻尼金属基复合材料,以高温烧结后的大晶粒钛酸钡(BaTiO3)陶瓷作为增强体,通过粉末冶金和热挤压方法制备钛酸钡颗粒增强铝基复合材料,并研究其阻尼特性和力学特性。动态力学分析结果表明,大晶粒钛酸钡陶瓷本身具有很好的阻尼性能,阻尼值可达0.12。但在纯铝基体中加入质量分数为10%BaTiO3制备的BaTiO3/Al复合材料的室温阻尼性能和铝基体相比并无明显改善,而450 K以上的阻尼性能由于界面附近的位错运动而大幅度提高。钛酸钡增强体的本征阻尼性能未能充分发挥的原因在于钛酸钡颗粒与铝基体之间的界面结合不良,导致钛酸钡颗粒内部的能量耗散机制无法触动。复合材料的拉伸性能比相应纯铝基体的提高了42%,这意味通过改善界面结合和加入高含量的碳酸钡阻尼增强颗粒,有望获得高强度高阻尼金属基复合材料。

关键词:高阻尼材料;金属基复合材料;钛酸钡;力学性能;界面

(Edited by YUAN Sai-qian)

Foundation item: Project (51001071) supported by the National Natural Science Foundation of China; Projects (2012CB619400, 2012CB619600) supported by the National Basic Research Program of China; Project (2010DFA52550) supported by the International S&T Cooperation Program of China; Project (20100470031) supported by China Postdoctoral Science Foundation

Corresponding author: ZHANG Di; Tel:+86-21-34202634; Fax: +86-21-34202749; E-mail: zhangdi@sjtu.edu.cn

DOI: 10.1016/S1003-6326(11)61493-3