在压力场下从石煤中提取五氧化二钒的工艺

李旻廷,魏昶,李存兄,邓志敢,李兴彬,樊刚

(昆明理工大学 冶金与能源工程学院,云南 昆明,650093)

摘 要:对贵州某地石煤进行加压酸浸提钒实验研究。在压力场条件下考察几种主要因素对钒浸出率的影响。得到的最佳技术条件为:反应时间3 h,硫酸质量浓度200 g/L,浸出温度180 ℃,搅拌转速580 r/min;在此条件下,钒浸出率(质量分数)为76%。两段逆流浸出实验结果表明:钒浸出率可达90%以上。浸出液经过废酸回收、还原、调整pH等预处理后,采用溶剂萃取的方法能够有效地分离和富集钒,钒萃取率可达98.1%,反萃率为99.14%;用氨水沉淀反萃液中的钒,沉淀物(多聚钒酸铵)在550 ℃煅烧3 h即可产出纯度为99% V2O5;全流程钒回收率为85%左右。

关键词:钒;石煤;加压酸浸;溶剂萃取

中图分类号:TF841.3 文献标志码:A 文章编号:1672-7207(2010)04-1268-08

Technics for vanadium pentoxide extraction from black shale in pressure field

LI Min-ting, WEI Chang, LI Cun-xiong, DENG Zhi-gan, LI Xing-bin, FAN Gang

(Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: The extraction of vanadium from black shale in Guizhou was investigated by pressure acid leaching. The effects of main factors on leach recovery were investigated in pressure field. Optimum parameters for the leaching of vanadium for one-step leaching are: reaction time of 3 h, sulfuric acid concentration of 200 g/L, leaching temperature of 180 ℃ and stirring speed of 580 r/min. Under these conditions, about 76% vanadium is recovered. A two-step countercurrent leaching process is developed, and the vanadium recovery of 90% is obtained. Vanadium in the leachate is efficiently separated and enriched by solvent extraction after several preprocesses namely. The extraction and stripping yields of vanadium are 98.1% and 99.41%, respectively. Ammonia is employed to precipitate vanadium in the stripping liquor, subsequently and then the precipitates (ammonium poly-vanadate) are calcined at 550 ℃ for 3 h to produce 99% V2O5. The overall yield of vanadium through all process stages is about 85%.

Key words: vanadium; black shale; pressure acid leaching; solvent extraction

自然界中很少有单独的钒矿床存在,通常伴生在钒钛磁铁矿、磷盐矿、碳沥青、石煤、石油灰渣、铀钒矿和钾钒矿等矿床中。石煤是我国除钒钛磁铁矿外另一种重要钒矿资源,广泛分布于云南、贵州、湖南、浙江、江西、广西、甘肃、新疆等省(区)。石煤中赋存的金属和非金属元素有60余种,有工业利用价值、品位较高的有20多种,如V,Mo,Ag,Y,Ga和Se等,故被认为是一种低品位多金属复杂矿。我国石煤储量为6l8.8×108 t,其中含钒1.18×108 t,占我国V2O5总储量的87%[1]。从石煤中提取钒的传统工艺是钠化焙烧—水浸(或低酸浸出),该流程相对于其他工艺流程来说,对各地石煤矿具有较强的适应性;缺点是钒回收率较低(通常<50%)、对环境污染较严重。随着环境问题日益突出,该流程已逐步被取缔。一些研究者为了提高钒回收率和减轻环境负担,对石煤提钒进行了大量的研究。郑祥明等[2]采用分段溶解法提取石煤中的五氧化二钒,采用浮选去除石煤中大部分碳后,先在稀盐酸介质中溶解氧化物中的钒,然后,用盐酸和亚铁盐浸取硅铝酸盐中钒,使大部分钒转入溶液中,浸出液经氧化处理料液后,料液经过离子树脂交换,一次提取即可获得纯度(质量分数)达97.0%的五氧化二钒产品,钒回收率在85%以上。鲁兆伶[3]采用“酸浸—P204萃取—硫酸反萃取—氨水沉淀—煅烧制精钒”工艺流程从西北含钒石煤中提取五氧化二钒。在其实验条件下,用硫酸溶液可以浸出石煤中约80%的钒。用P204和TBP的磺化煤油溶液萃取、硫酸溶液反萃取可得到较纯的五氧化钒溶液,再经氨水沉淀、热解,可得到纯度在98%以上的精钒产品。该工艺于1996年在我国西北地区实现了工业化生产。此外,针对含钙高的石煤资源,陆芝华等[4]开发出氧化焙烧一稀碱浸出工艺;欧阳昌伦等[5]开发出了氧化焙烧一稀酸浸出工艺;邹晓勇等[6]开发了钙化焙烧—酸浸工艺;蒋馥华等[7]则采用钙化焙烧—碱浸工艺流程来处理此类石煤矿。除钒钛磁铁矿外,国外提钒的原料主要是石油工业产生飞灰、石油焦、沥青和废催化剂等,采用的方法主要有焙烧—酸浸[8-9]、生物浸出[10-11]和直接酸浸[12]。作者曾对贵州某地含钒石煤进行了3种提钒实验方案的研究[13],即氧化焙烧—加压酸浸、常压酸浸、加压酸浸。结果表明:采用前2种方法所得的钒浸出均小于60%。由于焙烧过程产生了新的不溶于酸的钒包裹体物相而导致钒浸出率低,因此,本文作者采用加压酸浸—溶剂萃取的方法从石煤中提取五氧化二钒。该方法无传统的焙烧工序产生Cl2和HCl等有害气体,具有对环境友好的特点;同时,在较高的温度和酸度下,浸出时间大幅度缩短,仅3~4 h,而常压酸浸通常需要16~20 h。但本工艺对反应设备的材质要求较高(耐酸介质,通常为钛材),其生产成本比钠化焙烧工艺的低,比常压酸浸的略高。

1 实验

1.1 原料特性及分析

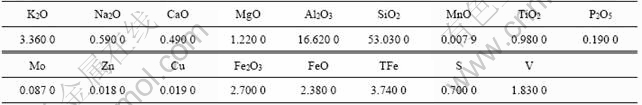

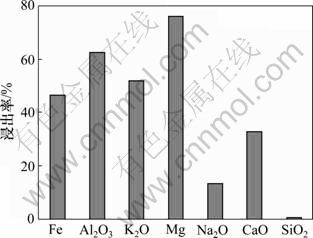

实验原料来至贵州某地,主要的化学成分如表1所示,扫描电镜像及能谱分析结果如图1所示。

由图1可知:钒主要分布于氧化铁、黏土类矿物和云母类矿物中,极少量的钒存在于难溶硅铝酸盐矿物中。

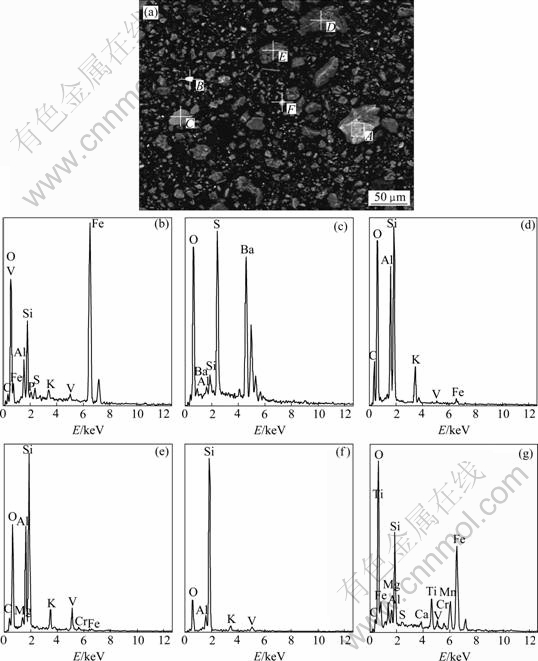

1.2 石煤中钒的赋存状态

石煤的矿物组成复杂多变,分散细微,钒的赋存状态及价态呈现多变性。按含钒矿物的种类划分,可分为3类[14]:含钒氧化铁及黏土、含钒云母类和含钒难溶硅铝酸盐(如电气石、石榴石等)。表2所示为实验用矿样钒的物相及价态分析结果。

从表2可以看出:钒主要以类质同象形式赋存于云母类矿物,这部分的钒(V2O5)含量为2.627%,占总钒80.53%;其次,以吸附形式存在于氧化铁及黏土类矿物;剩余极少量的钒以类质同象形式存在于难溶硅铝酸盐矿物中。

各地石煤原矿中一般只有三价钒和四价钒存在,极少发现二价钒和五价钒。除了个别地方石煤中四价钒含量高于三价钒含量外,绝大部分地区石煤中钒都是以三价钒为主[15-16]。从表2可看出:实验用矿样中3种价态的钒含量相差不大,且五价钒含量最高,其次是三价钒。这与文献[15]的研究结果有较大差别,这进一步说明石煤中钒赋存状态的复杂和多变。石煤矿中高价态的钒含量越高,对于钒的浸出越有利。结合钒的物相分析可知:三价钒和四价钒主要是以类质同象形式存在于云母矿物中,五价钒则以吸附形式存在于氧化铁及黏土矿物中。

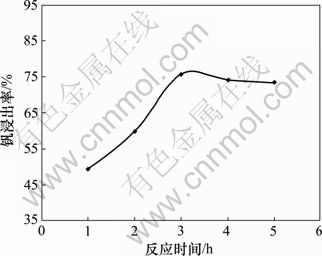

表1 原料的化学成分(质量分数)

Table 1 Chemical composition of black shale sample %

(a) 石煤矿SEM像;(b) A点能谱;(c) B点能谱;(d) C点能谱;(e) D点能谱;(f) E点能谱;(g) F点能谱

图1 石煤矿扫描电镜像及能谱分析结果

Fig.1 SEM image and EDS patterns of black shale sample

1.3 实验方法

矿石中粒度小于0.074 mm的颗粒占85%(质量分数),称取该原料200 g,控制一定实验条件进行调浆。待浆料加入反应釜后,开始加热升温,到达预设温度后开始计时,同时向高压釜通入氧气。恒温结束后,取出浸出浆料进行液固分离,分析渣相中的钒含量,计算钒浸出率。在压力场条件下,考察反应时间、硫酸质量浓度、反应温度、搅拌转速、添加剂FeSO4质量浓度对钒浸出率的影响,同时进行两段逆流浸出 实验。

两段逆流浸出得到的Ⅰ段浸出液经过废酸回收、还原、调节pH等预处理后,采用P204为萃取剂进行6级连续萃取,采用H2SO4为反萃剂进行5级反萃,反萃液在60 ℃氧化1 h后,采用氨水为沉钒剂,于90 ℃进行沉钒,红饼过滤洗涤后于550 ℃煅烧即可得到粉状V2O5。

表2 实验用矿样钒的物相及价态分析结果

Table 2 Phase and valence state of vanadium in used sample

2 结果及讨论

2.1 加压酸浸实验

固定实验条件为:矿石中粒度小于0.074 mm的颗粒占85%,浸出过程总压力为1.2 MPa,液固比为 1.2 mL/g。

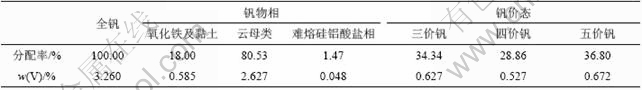

2.1.1 反应时间对钒浸出率的影响

在浸出温度为180 ℃、液固比为1.2 mL/g、硫酸质量浓度为200 g/L的条件下,浸出反应时间对钒浸出率的影响如图2所示。从图2可看出:随着反应时间的延长,钒浸出率迅速提高,在3 h达到最大值,为75.79%。此后再延长浸出时间,则钒浸出率基本不变,其原因有待进一步研究。在后续试验中浸出时间可控制在3 h。

图2 反应时间对钒浸出率的影响

Fig.2 Effect of reaction time on leach recovery of vanadium

2.1.2 硫酸质量浓度对钒浸出率的影响

在浸出温度为180 ℃、液固比为1.2 mL/g、反应时间为3 h的条件下,硫酸质量浓度对钒浸出率的影响如图3所示。从图3可知:随着硫酸质量浓度的增加,钒浸出率迅速提高;当硫酸质量浓度从200 g/L增加到330 g/L时,钒浸出率增加趋势变得缓慢,从74.23%增加到78.24%,仅提高4%。同时,由于初始硫酸质量浓度越高,浸出液中的残余硫酸质量浓度也越高;当硫酸质量浓度为330 g/L时,残余硫酸质量浓度也达到65 g/L。如果不回收这部分硫酸,就会增加后续溶液中和工序中的试剂用量。因此,硫酸质量浓度为200 g/L较为合适。

图3 硫酸质量浓度对钒浸出率的影响

Fig.3 Effect of H2SO4 concentration on leach recovery of vanadium

2.1.3 反应温度对钒浸出率的影响

在液固比为1.2 mL/g、硫酸质量浓度为200 g/L、反应时间为3 h的条件下,浸出温度对钒浸出率的影响如图4所示。从图4可知:反应温度对钒浸出率有显著影响,钒浸出率从120 ℃时的40.68%增加到180 ℃的75.30%,增加了34.38%,这表明化学反应可能是钒氧化溶解速率的重要控制步骤。反应方程如下:V2O3+O2+2H+→2VO2++H2O+3e;V2O4+4H+→2VO2++ 2H2O;V2O5+2H+→2VO2++H2O。故在后续实验中浸出温度选为180 ℃。

2.1.4 搅拌转速对钒浸出率的影响

在浸出温度为180 ℃、液固比为1.2 mL/g、反应时间为3 h、硫酸质量浓度为200 g/L的条件下,搅拌转速对钒浸出率的影响如图5所示。从图5可看出:在搅拌转速为100~500 r/min范围内,钒浸出率随搅拌转速增加而显著增加,从41.0%增加到73.8%,增加了32.8%。此后,再增加搅拌转速,钒浸出率基本不变。这表明当搅拌转速增加到500 r/min以上时,颗粒表面的液膜边界层达到一个极小值,此时,搅拌转速对钒浸出率的影响被消除,浸出反应的速率控制步骤转变为液膜控制或化学反应控制,但对于判断过程的机理尚需进一步的实验研究。为了确保足够的搅拌转速,在后续试验中搅拌转速仍控制在580 r/min。

图4 反应温度对钒浸出率的影响

Fig.4 Effect of temperature on leach recovery of vanadium

图5 搅拌转速对钒浸出率的影响

Fig.5 Effect of stirring speed on leach recovery of vanadium

2.1.5 添加剂质量浓度对钒浸出率的影响

为了提高溶液中氧的传递速率,改善氧化反应的动力学条件,利用Fe3+可以传递氧的作用,对低价钒进行氧化。在浸出温度为180 ℃、液固比为1.2 mL/g、硫酸质量浓度为200 g/L、反应时间为3 h的条件下,考察不同FeSO4质量浓度对钒浸出率的影响,结果如图6所示。从图6可见:FeSO4质量浓度为6.6 g/L时钒浸出率已达75.2%,比没有加入FeSO4时提高了5%。此后,再增加FeSO4质量浓度,钒浸出率基本不再提高。这是由于原料中Fe含量为3.74%,在浸出反应过程中,一部分的Fe逐渐被溶出,起到了传递氧的作用,因而FeSO4质量浓度对钒浸出率没有显著影响。

图6 FeSO4质量浓度对钒浸出率的影响

Fig.6 Effect of FeSO4 concentration on leach recovery of vanadium

根据上述分析,得到最佳工艺参数如下:反应时间为3 h,硫酸质量浓度为200 g/L,反应温度为180 ℃,搅拌转速为300 r/min,添加剂质量浓度为6.6 g/L,在此条件下进行了3组平行实验,钒浸出率分别为75.23%, 76.4%和76.79%,平均值为76%左右。

2.1.6 两段逆流浸出

为了进一步提高钒浸出率同时降低体系温度,对浸出过程进行优化,采用了两段逆流浸出的方法。逆流浸出实验由5次单元实验组成。单元实验条件如下。

Ⅰ段:反应时间为3 h,硫酸质量浓度为200 g/L,反应温度为150 ℃,液固比为1.2 mL/g,添加剂质量浓度为6.6 g/L。

Ⅱ段:反应时间为4 h,硫酸质量浓度为330 g/L,反应温度为150 ℃,液固比为1.2 mL/g,添加剂质量浓度为6.6 g/L。

Ⅰ段和Ⅱ段搅拌转速均为580 r/min,总压力为1.2 MPa。实验结果如表3所示。

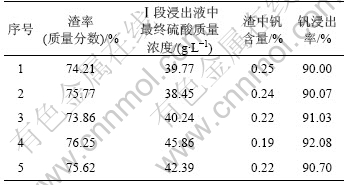

从表3可看出:采用两段逆流浸出方法后,单元实验的钒浸出率均在90.00%以上,比Ⅰ段浸出的浸出率76.00%提高了14.00%。实验还考察了原料中主要杂质金属的浸出率,结果如图7所示。从图7可见:由于酸性浸出的选择性较差,原料中的杂质金属均不同程度地被溶出。其中,75%左右的Mg进入溶液,其余金属如Fe,Al2O3,K2O,Na2O和CaO,浸出率在30%~60%之间。由于原料中的SiO2含量达到53.03%,若有较多可溶性的硅被溶出,则会给浆料的过滤带来极大困难。实验结果表明:原料中SiO2基本不被溶出,SiO2浸出率仅为0.7%。

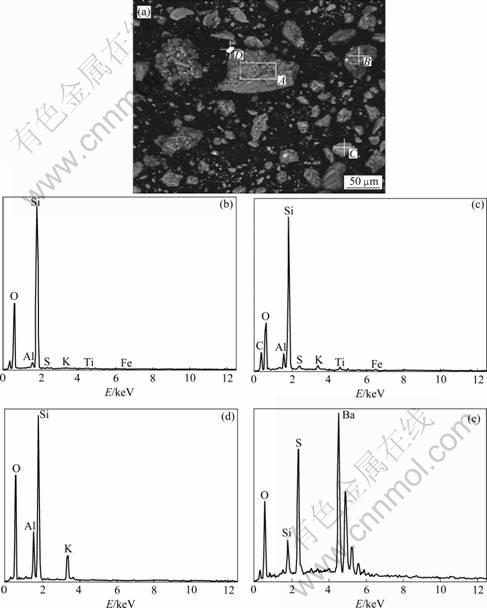

表3 两段逆流浸出实验结果

Table 3 Experimental results of two-step countercurrent leaching

2.1.7 浸出渣的表征

浸出渣扫描电镜像和能谱分析结果如图8所示。对比图1和图8可知:经过两段逆流浸出后,原料中氧化铁及黏土、云母类矿物中的钒已基本上被溶出。

图7 原料中主要杂质金属的浸出率

Fig.7 Leaching recovery of main metal impurity in material

(a) 浸出终渣SEM像;(b) A点能谱;(c) B点能谱;(d) C点能谱;(e) D点能谱

图8 浸出终渣的扫描电镜像和能谱分析结果

Fig.8 SEM image and EDS patterns of leach residue

2.2 从溶液中提取钒

从溶液中提取钒有直接氧化沉淀[17]、直接沉淀或还原后沉淀[18]和溶剂萃取[19-21]。采用溶剂萃取的方法,料液为两段逆流浸出实验得到的Ⅰ段浸出液,其化学成分见表4。

表4 Ⅰ段浸出液的主要成分(质量浓度)

Table 4 Main compositions in Ⅰ leachate g/L

如前述分析,由于酸性浸出的选择性较差,原料中其他杂质金属均不同程度地被溶出。从表4可见:溶液中杂质含量较高,不利于后续从溶液中提取V2O5,同时,溶液中酸度较高,在萃取之前需要对溶液进行预处理。

2.2.1 溶液预处理

浸出液中含有大量的残余H2SO4,如果不回收这部分硫酸,会增加中和试剂的用量,使生产成本升高。从硫酸体系中回收硫酸已有研究[21],由于浸出液中并无硅胶产生(硅胶会堵塞扩散渗析膜),因此,本文采用扩散渗析器回收这部分H2SO4。结果表明:H2SO4回收率为85%,钒截留率为96%,其余杂质金属截留率均在90%以上,处理后溶液(残液)中H2SO4质量浓度为6.5 g/L左右。废酸回收为下一步用氨水调整pH时节省了氨水用量,同时提高了H2SO4利用率,其回收成本低。由于实验采用的萃取剂(P204)在萃取钒的同时亦能萃取三价铁离子,从而导致萃取剂使用效率低、产品杂质含量高,因此,在萃取之前还必须将三价铁离子还原成二价铁离子。使用Na2SO3为还原剂,其用量为化学反应理论用量的1倍,Fe3+的还原率可达98.20%。

2.2.2 溶液中钒的萃取及反萃取

前期萃取实验结果表明:10% P204+5% TBP+85% (质量分数)磺化煤油体系对钒有较好的萃取效果。在萃取剂组成为10% P204+5% TBP+85%磺化煤油、有机相与水相体积比为1?1、室温、初始水相pH为2.3、时间为10 min的条件下,经过6级萃取,钒萃取达98.1%;在反萃剂H2SO4质量浓度为160 g/L、有机相与水相体积比为5?1~8?1、室温、时间为15 min的条件下,经过5级反萃,钒的反萃取率可达99.14%。反萃液中V2O5质量浓度为75.0~84.0 g/L,Fe质量浓度为0.5~0.8 g/L,钒分离和富集的效果较好。

2.2.3 钒的沉淀及煅烧

无论采用何种提钒方法,到最后都采用氨水或铵盐来沉淀溶液中的钒。由于反萃液中的钒是以四价钒的形式存在的,因此,在沉淀之间必须将其氧化成五价钒。氧化剂为200 g/L的NaClO3溶液,在温度为60 ℃下氧化1 h,随后,将温度升高到90 ℃,向氧化后的溶液中加入18%氨水,其用量保证NH4+和五价钒的物质的量比大于3。由于V2O5在pH为2.0左右的溶解度最小,因此,沉淀初始pH控制在2.0,钒沉淀率为98.2%。对得到的红饼经过洗涤、干燥,于550 ℃热解3 h即可得到的V2O5粉末,V2O5产品纯度大于99%。全流程V2O5回收率为85%左右。

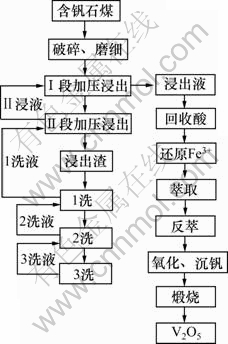

2.3 五氧化二钒的回收流程

在压力场下从石煤中提取五氧化二钒的工艺流程包括加压酸浸、溶液预处理、还原、溶剂萃取、反萃、氧化、沉钒等过程,其工艺流程如图9所示。

图9 在压力场下从石煤中提取V2O5的工艺流程图

Fig.9 Flow sheet for extraction of V2O5 from black shale under pressure field

3 结论

(1) 研究了浸出过程各主要因素对钒浸出率的影响,得到最佳工艺参数如下:反应时间为3 h,硫酸质量浓度为200 g/L,反应温度为180 ℃,搅拌转速为580 r/min,添加剂质量浓度为6.6 g/L。在此条件下钒浸出率可达76%。经过两段逆流浸出后,钒浸出率可达90%以上。

(2) 采用85%煤油+10% P204+5% TBP的萃取体系,能够很好地分离和富集钒,钒的萃取率和反萃取率分别为98.1%和99.41%,全流程钒回收率可达85%左右。

参考文献:

[1] 宾智勇. 石煤提钒研究进展与五氧化二钒的市场状况[J]. 湖南有色金属, 2006, 22(1): 16-20.

BIN Zhi-yong. Progress of the research on extraction of vanadium pentoxide from black shale and the market of the V2O5[J]. Hunan Nonferrous Metals, 2006, 22(1): 16-20.

[2] 郑详明, 田学达, 张小云, 等. 湿法提取石煤中钒的新工艺研究[J]. 湘潭大学自然科学学报, 2003, 25(1): 43-45.

ZHENG Xiang-ming, TIAN Xue-da, ZHANG Xiao-yun, et al. Extraction of vanadium pentoxide from stone coal with a wet chemical separation method[J]. Natural Science Journal of Xiangtan University, 2003, 25(1): 43-45.

[3] 鲁兆伶. 用酸法从石煤中提取五氧化二钒的试验研究与工业实践[J]. 湿法冶金, 2002, 21(4): 175-183.

LU Zhao-ling. Investigation and industrial practice on extraction of V2O5 from black shale containing vanadium by acid process[J]. Hydrometallurgy of China, 2002, 21(4): 175-183.

[4] 陆芝华, 周邦娜, 余仲兴, 等. 石煤氧化焙烧 —— 稀碱溶液浸出提钒工艺研究[J]. 稀有金属, 1994, 18(5): 321-327.

LU Zhi-hua, ZHOU Bang-na, YU Zhong-xing, et al. Craft sthdy on extracting vanadium form black shale by means of oxidation roasting: Diluted alkali solution[J]. Chinese Journal of Rare Metals, 1994, 18(5): 321-327.

[5] 欧阳昌伦, 谢香兰, 滕代明. 石煤无盐焙烧萃取提钒工艺浅析[J]. 煤炭加工与综合利用, 1993(1): 11-13.

OUYANG Chang-lun, XIE Xiang-lan, TENG Dai-ming. A process analysis of extracting vanadium from black shale by no salt-roasting, extracting[J]. Coal Processing & Comprehensive Utilization, 1993(1): 11-13.

[6] 邹晓勇, 欧阳玉祝, 彭清静, 等. 含钒石煤无盐焙烧酸浸生产五氧化二钒工艺的研究[J]. 化学世界, 2001, 42(3): 117-119.

ZOU Xiao-yong, OUYANG Yu-zhu, PENG Qing-jing, et al. Study on the process of producing vanadium pentoxide from bone coal vanadium mine by no-salt-roasting and acid leaching[J]. Chemical World, 2001, 42(3): 117-119.

[7] 蒋馥华, 张萍, 申照全. 石煤中提钒的无污染新工艺[J]. 化学世界, 1992, 33(12): 538-540.

JIANG Fu-hua, ZHANG Ping, SHEN Zhao-quan. A new craft characterized by no pollution on extracting vanadium from black shale[J]. Chemical World, 1992, 33(12): 538-540.

[8] Holloway, P C, Etsell, T H. Process for the complete utilization of oil sands fly ash[J]. Canadian Metallurgical Quarterly, 2005, 45(1): 25-32.

[9] Shelwit H, Alibrahim M. Extraction of sulfur and vanadium from petroleum coke by means of salt-roasting treatment[J]. Fuel, 2006, 85(5/6): 878-880.

[10] Mishra D, Kim D J, Ralph D E, et al. Bioleaching of vanadium rich spent refinery catalysts using sulfur oxidizing lithotrophs[J]. Hydrometallurgy, 2007, 88(4): 202-209.

[11] Mishra D, Kim D J, Ralph D E, et al. Bioleaching of spent hydro-processing catalyst using acidophilic bacteria and its kinetics aspect[J]. Journal of Hazardous Materials, 2008, 152(3): 1082-1091.

[12] Navarro R, Guzman J, Saucedo I, et al. Vanandium recovery from oil fly by leaching, precipitation and solvent extraction process[J]. Waste Management, 2007, 2(3): 425-438.

[13] 李旻廷, 魏昶, 樊刚, 等. 石煤氧压酸浸提钒探索试验研究[J]. 稀有金属, 2007, S31: 28-31.

LI Min-ting, WEI Chang, FAN Gang, et al. The pathbreaking experimentation study on extracting vanadium from stone-coal by acid leaching with oxygen pressure[J]. Chinese Journal of Rare Metals, 2007, S31: 28-31.

[14] 肖文丁. 广西上林石煤的矿物学和湿法提钒研究[J]. 有色金属, 2007, 59(3): 85-90.

XIAO Wen-ding. Mineralogy of stoI/e coal from Shanglin of Guangxi and vanadium extraction with hydrometallurgical process[J]. Nonferrous Metals, 2007, 59(3): 85-90.

[15] 许国镇. 石煤中钒的价态及物质组成对提钒工艺的指导作用[J]. 煤炭加工与综合利用, 1989(5): 5-8.

XU Guo-zhen. Guidance function of vanadium valence and material composition in black shale to extracting vanadium process[J]. Coal Processing & Comprehensive Utilization, 1989(5): 5-8.

[16] 许国镇, 张秀荣, 尹光衡. 江西玉山石煤烧结包裹与钒转化的研究[J]. 现代地质, 1993, 7(1): 109-117.

XU Guo-zhen, ZHANG Xiu-rong, YIN Guang-heng. Sintering of black shale and the transformation of vanadium in Yushan Jiangxi province[J]. Geoscience, 1993, 7(1): 109-117.

[17] Sandra IVtolo, Maurizia Seggiani. Recovery of vanadium from heavy oil and Orimulsion fly ashes[J]. Hydrometallurgy, 2007, 57(2): 141-149.

[18] Lozano L J, Juan D. Technical note leaching of vanadium from spent sulphuric acid catalysts[J]. Minerals Engineering, 2001, 14(5): 543-546.

[19] Olazabal M A, Fernandez M M, Madariaga L A, et al. Selective extraction of vanadium(Ⅴ) from solution containing molybdenum(Ⅳ) by ammonium salts dissolved in toluene[J]. Solvent Extraction and Ion Exchange, 1992, 10(4): 623-635.

[20] Zhang P W, Inoue K, Yoshizuka K, et al. Extraction and selective stripping of molybdenum(Ⅳ) and vanadium(Ⅴ) from sulfuric acid solution containing aluminum(Ⅲ), cobalt(Ⅱ), nickel(Ⅱ) and iron(Ⅲ) by LIX63 in Exxsol D80[J]. Hydrometallurgy, 1996, 41(1): 45-53.

[21] Jeong J, Kim M S. Recovery of H2SO4 from waste acid solution by a diffusion dialysis method[J]. Journal of Hazardous Materials, 2005, 124(1/3): 230-232.

收稿日期:2009-08-18;修回日期:2009-11-04

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z130);云南省科技厅支持项目(2007GA010);昆明理工大学优秀博士学位论文培育基金资助项目(2008年)

通信作者:魏昶(1962-),男,云南昆明人,教授,博士研究生导师,从事湿法冶金研究;电话:0871-5188819;E-mail: weichang2008@sina.com

(编辑 陈爱华)