DOI: 10.11817/j.issn.1672-7207.2015.02.007

基于末端淬火试验研究3种7000系铝合金的淬透性

张新明1, 2,张端正1, 2,刘胜胆1, 2,李承波1, 2,邓运来1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:通过末端淬火方法研究 7055,7050和7085 3种铝合金厚板的淬透性,采用扫描电镜和透射电子显微镜对微观组织进行分析。研究结果表明:3种合金的淬透层深度分别约45 mm,60 mm和100 mm以上,两端的硬度分别为14%,12%和6%,3种合金的硬度与冷却速率的对数呈线性关系,曲线斜率依次减小。7055和7050合金中Zn与Mg质量比低(Mg含量高),Cu含量高,导致淬火速率低时晶内析出尺寸更大、数量更多的η平衡相,同时也促进了T相和S相的析出,时效后平衡相的周围出现明显的无沉淀析出带,导致硬度下降明显,合金的淬透性大大降低。

关键词:Al-Zn-Mg-Cu合金;末端淬火;淬透性;淬火析出相

中图分类号:TG146.21 文献标志码:A 文章编号:1672-7207(2015)02-0421-06

Hardenability of three 7000 series aluminum alloys based on Jominy end quench test

ZHANG Xinming1, 2, ZHANG Duanzheng1, 2, LIU Shengdan1, 2, LI Chengbo1, 2, DENG Yunlai1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2.Key Laboratory of Nonferrous Metal Materials Science and Engineering,

Ministry of Education, Changsha 410083, China)

Abstract: The hardenability of 7055, 7050 and 7085 aluminum alloy thick plates was studied by end quenching test. The microstructure was investigated by scanning electron microscopy and transmission electron microscopy. The results show that the hardened depths of the three plates are 45 mm, 60 mm and 100 mm, the hardness differences of the three alloys are 14%,12% and 6% respectively from spray end to the other one. There exists a linear relationship between hardness and the logarithm of cooling rate and the slopes of curves decrease in sequence. The low mass ratio of Zn to Mg (high Mg content) and high Cu content of 7055 and 7050 alloys result in more equilibrium η phases with larger size precipitation during slow cooling rate, and accelerate the precipitation of T phases and S phases. After aging, obvious precipitation free zone (PFZ) is observed around the equilibrium phases, causing hardness decreased distinctly and hardenability reduced greatly.

Key words: Al-Zn-Mg-Cu alloy; end quenching; hardenability; precipitation

7000系铝合金具有密度低、强度高、较好的加工性能等特点而广泛用于航天、航空和汽车工业等领域。近年来,为了减轻质量、降低成本,飞机结构件向着大型化及整体化的方向发展,对大截面的7000系合金厚板及锻件提出了迫切需求。但该系铝合金存在淬火敏感性,其力学性能随淬火速率的减小而降低[1-2]。淬火敏感性的产生是缓冷时平衡相在弥散粒子、晶界及亚晶界上析出[3-4],降低合金的过饱和度、减弱时效强化效果造成的。因此,为了获得最佳的时效强化效果,材料固溶后必须快速淬火。而随着厚板厚度的增加,尤其是为了减小淬火残余应力而降低冷却强度时,材料中心部分的淬火速率往往达不到所需的临界冷却速率,性能下降,出现淬不透的现象。因此7000系铝合金厚截面材料的淬透性问题引起了人们广泛的关注。影响7000系铝合金淬火敏感性的因素也是影响其淬透性的因素,主要包括合金的化学成分、制备工艺及微观组织[5-6]。其中,主合金元素对淬火敏感性的影响十分显著,Zn,Mg和Cu元素含量增加通常都会提高合金的淬火敏感性[7-8]。许多学者在这方面展开了大量研究。陈慧[9]认为Cu对淬火敏感性的影响最大,其次是Mg和Zn。Lim等[10]研究表明:降低Cu+Mg总量和提高Zn与Mg质量比可显著降低7175铝合金的淬火敏感性,Zn与Mg质量比增加可推迟固溶体的分解。Deng等[11]通过末端淬火实验研究了Mg含量对7085型铝合金淬火敏感性的影响,结果表明:合金中Mg质量分数为1.0%,1.4%和2.0%时,距离喷水端105 mm处的硬度较5 mm处分别下降了9%,15%和18%。末端淬火方法是研究时效强化铝合金厚截面材料淬透性的有效途径,伊琳娜等[12]对7B04锻件的淬透性开展了研究;熊柏青等[13]采用末端淬火方法对7150,7B04及新型合金Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr的淬透性进行了评价。在此,本文作者以7055,7050和7085铝合金为对象,采用末端淬火的方法,研究合金成分与淬火析出相间的关系,探明合金成分对淬透性的影响规律和机理。

1 实验材料及方法

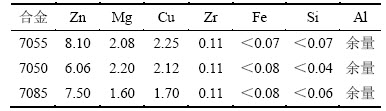

研究所采用的材料是7055,7050和7085铝合金热轧板材,其成分如表1所示。在热轧板上沿轧向切取长×宽×厚为125 mm×25 mm×25 mm的端淬样品。一端车出深10 mm,直径为20 mm的凹槽,作为喷水端,另一端钻出深10 mm,M5 mm的螺纹孔。在SX-4-10型箱式电阻炉中加热升温至470 ℃,保温1 h后,样品转移到末端淬火装置[14]上并迅速向凹槽端喷水冷却,水温约为20 ℃,待样品冷却后,样品放入120 ℃的油浴炉中时效24 h。时效后样品从中间一分为二按维氏硬度测试的要求打磨表面,从喷淋端开始,每隔5 mm位置测一次硬度(HV),取与中心线垂直方向上5个硬度的平均值作为淬透性曲线上该位置的硬度,获得硬度与距离的关系曲线。

另取一样品在距喷淋端3,23,53,78和98 mm处钻出直径为3 mm小孔预埋热电偶,测得这5个位置的冷却曲线。由于7055合金的淬火敏感性最大,其淬火敏感区间也最大,因此在230~420 ℃[15]温度区间计算出平均冷却速率,分别为20.83,10.50,2.73,2.30和2.25 ℃/s。

在试样不同位置截取样品进行微组织分析,样品经粗磨、细磨、抛光后在到FEI Quanta-200扫描电镜上进行显微组织观察和能谱分析。透射电镜分析在荷兰FEI产的TECNAIG220型TEM电镜上进行,加速电压为200 kV。透射电镜观察的样品先磨成厚度为0.08 mm薄片,冲成直径为3 mm圆片后进行双喷减薄。电解液为20%HNO3+80%CH3OH(体积分数),温度控制在-20 ℃以下。

表1 3种合金的化学成分(质量分数)

Table 1 Chemical composition of three alloys %

2 实验结果

2.1 淬透性曲线

图1所示为3种合金的淬透性曲线。由图1(a)可见:3条曲线的趋势基本一致,硬度随距淬火端距离的增加而降低。7055合金和7050合金的硬度较高,硬度随端距的增加而快速下降,而后硬度变化不大。7085合金的曲线在最下方且硬度下降较缓慢。当端距超过80 mm,硬度随距离的增加变化不大。为了研究不同合金的硬度变化情况,通过不同合金的淬透性曲线,算出3种合金的硬度下降程度,如图1(b)所示。由图1(b)可见:7055合金在63 mm处的硬度下降比例为14%且以后基本不变;7050合金在68 mm处的硬度下降比例为12%且以后基本不变;7085合金距离喷水端98 mm处的硬度比3 mm处的硬度下降约6%。若规定硬度下降10%处的端距为淬透层深度,则7055,7050和7085合金的淬透层深度分别为45 mm,60 mm和100 mm以上。显然,7055合金的淬透性最差,而7085合金具有很好的淬透性。

图1 3种合金的淬透性曲线

Fig. 1 Hardenability curves of three alloys

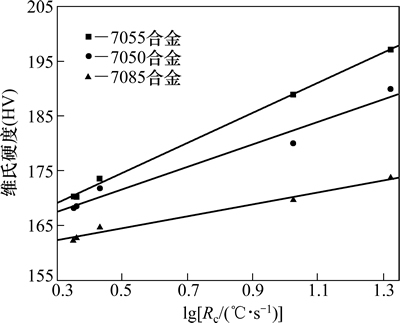

图2所示为3种合金时效后的硬度与冷却速率间的关系。从图2可以看出:3种合金的硬度与冷却速率的对数近似呈线性关系,随冷却速率的减小,硬度不断减小。7085合金曲线的斜率最小;7055合金曲线的斜率最大,约是前者的2.5倍;7050合金曲线的斜率居中。这说明随冷却速率的减小,7085合金的硬度下降最小,7050合金的次之,7055合金的最大。因此,7055合金的淬透性最差。对这3条曲线进行线性拟合,其线性相关系数分别为0.998 9,0.988 4和0.991 3,因此,硬度(H)与冷却速率(RC)的对数有较好的线性关系。7055,7050和7085合金的拟合结果分别为:

(1)

(1)

(2)

(2)

(3)

(3)

2.2 显微组织

图3所示为3种合金的扫描照片。从图3可以看出:在冷却速率很大时,除了存在一些白色的初生相外,观察不到平衡相的析出。在冷却速率很小时,7055合金沿轧向有明显的白色析出带,经能谱分析,该相是MgZn2相,同时晶内也能观察到大量的析出;而对于7050合金,冷却速率低时,晶界及晶内能看到一些析出相,晶界的析出较为明显,但晶内的析出没有7055合金那么明显;而对于7085合金,晶内的析出相不明显,晶界处的析出也较少。这说明冷却速率低时,7085合金析出相最少,7050合金次之,7055合金析出相最多。

图2 3种合金的硬度与冷却速率的关系

Fig. 2 Relationship between hardness and cooling rate of three alloys

图4所示为3种合金的TEM照片。从图4可见:冷却速率高时,淬火过程中平衡相的析出被抑制,所以7055合金晶内几乎观察不到粗大平衡相的存在,如图4(a)所示。而当冷却速率很低时,7055合金晶内有大量平衡相析出,形状为板条状,尺寸很大且不均匀,最大的可达1 μm,析出相之间没有位相关系,如图4(b)所示。在7055铝合金晶内除了可以观察到大量平衡η相外,还能看到一些六边形的析出相,其平均粒径约为174 nm,其周围的时效析出相明显减少,据文献[16]报道该相应该是T相,如图4(c)所示。在7055铝合金晶内还能观察到一些针状相,其最大粒径可达500 nm,在其周围存在明显的无沉淀析出带,据文献[17-18]报道该相应该是S相,如图4(d)所示。冷却速率很低时,7050合金晶内也析出了大量的板条状的平衡η相,并且部分平衡η相是以Al3Zr粒子作为形核核心。在这些平衡相的周围,时效析出相很少,远离平衡相的位置能观察到明显的时效析出相。同时还能观察到少量的T相,如图4(e)所示。对于7085合金,在冷却速率很低时,晶内析出的平衡η相较少,粒径较小,约为52 nm,未观察到T相和S相的析出,如图4(f)所示。

图3 3种合金的SEM照片

Fig. 3 SEM images of three alloys

图4 3种合金时效后的TEM照片

Fig. 4 TEM images after artifical aging of three alloys

表2 冷却速率为2.30 ℃/s时3种合金晶内η相的粒径和含量

Table 2 Size and area fraction of η phases within grains for three alloys cooled at cooling rate of 2.30 ℃/s

3 分析与讨论

表2所示为冷却速率在2.30 ℃/s时,3种合金晶内η相的尺寸和含量。从表2可以看出:7055合金析出相的尺寸及含量最大,7050合金次之,7085合金最小。7055合金η相的平均尺寸为590 nm,其面积分数约为30%;与7050合金相比,其尺寸和面积分数分别约为7050合金的2.6倍和1.7倍;与7085合金相比,其尺寸和面积分数分别约为7085合金的11倍和6倍。这说明7055合金,在冷却速率低时,析出的平衡η相尺寸较大且含量多,因此,其淬透性较差。而7085合金的淬透性较好。

据透射电镜观察结果显示,7000系铝合金慢速率淬火过程中析出相为大量的η相和少量的T相和S相。这些淬火析出相在Godard等[18]对AA7010铝合金的淬火研究中也有报道,根据合金元素组成和合金固溶后微观组成的不同发现:Zn+Mg+Cu 含量的增加导致合金晶内粗大η平衡相的尺寸和数量均显著增加。同时,在Zn与Mg质量比较小的合金中的过剩的Mg原子容易促使慢速淬火时粗大相的析出。Mg含量的提高增加了慢速淬火过程中η相的析出,同时也促进了T相的析出,更多地消耗了过饱和固溶体中的Zn和Mg溶质原子。Cu 含量的增加导致Zn和Mg元素的固溶度下降,慢速淬火时非均匀平衡相的析出趋势增加,当Cu含量增加到一定数值时,还会导致晶内S相的析出,特别是当Mg和Cu 含量增加到一定数值时,晶内析出了更多的η平衡相,这也与陈慧等[9-10]的研究结果相符合,使得合金的时效硬度降低明显,因此合金的淬火敏感性大大增加,淬透性降低。

慢速率淬火过程中,合金中析出尺寸较大的第二相粒子,无论是η相,T相还是 S 相都将消耗大量时效强化过程中的重要元素 Zn和Mg,导致析出相周围形成为贫溶质原子区域,这些粗大平衡相比较稳定,在时效时会吸收周围的溶质原子继续长大,并在其周围形成无沉淀析出带,典型结果如图4(c)~4(f)所示。和基体相比,这些无沉淀析出带更软[2]。因此,当合金中存在大量无沉淀析出区时,不仅降低合金的力学性能,也会造成合金淬透性的恶化。

4 结论

1) 7055,7050和7085 3种合金的淬透层深度分别为45 mm,60 mm和100 mm以上,距离喷水端98 mm处硬度比3 mm处的分别下降14%,12%和6%,3种合金的硬度与冷却速率的对数呈线性关系,曲线斜率依次减小。

2) 7055和7050合金的Zn与Mg质量比低(Mg含量高),Cu含量高,导致淬火速率低时晶内析出尺寸更大数量更多的η平衡相,同时也促进了T相和S相的析出,时效后平衡相的周围出现了明显的无沉淀析出带,导致硬度下降明显,合金的淬透性大大降低。

参考文献:

[1] Robinson J S, Cudd R L, Tanner D A, et al. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119(1/2/3): 261-267.

[2] 刘胜胆, 张新明, 黄振宝. 淬火速率对7055铝合金组织和力学性能的影响[J]. 材料科学与工艺, 2008,12 (5): 650-653.

LIU Shengdan, ZHANG Xinming, HUANG Zhenbao. Effects of quenching rates on microstructure and mechanical properties of 7055 aluminum alloy[J]. Materials Science and Technology, 2008, 12 (5): 650-653.

[3] ZHANG Xinming, LIU Wenjun, LIU Shengdan, et al. Effect of processing parameters on quench sensitivity of an AA7050 sheet[J]. Materials Science and Engineering A, 2011, 528(3): 795-802.

[4] LIU Shengdan, LIU Wenjun, ZHANG Yong, et al. Effect of microstructure on the quench sensitivity of AlZnMgCu alloys[J]. Journal of Alloys and Compounds, 2010, 507(1): 53-61.

[5] 许晓静, 张允康, 邓平安, 等. 7085 铝合金的淬透性[J]. 材料热处理学报, 2014, 35(3): 58-62.

XU Xiaojing, ZHANG Yunkang, DENG Pingan, et al. Quench sensitivity of 7085 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2014, 35(3): 58-62.

[6] 刘文军. Al-Zn-Mg-Cu铝合金淬火析出行为及淬火敏感性研究[D]. 长沙: 中南大学材料科学与工程学院, 2011: 1-138.

LIU Wenjun. The research about the quench induced precipitation and quenching sensitivty of Al-Zn-Mg-Cu alloys[D]. Changsha: Central South University. School of Materials Science and Engineering, 2011: 1-138.

[7] 欧阳惠. Zn/Mg 比对Al-Zn-Mg-Cu合金淬火敏感性的影响究[D].长沙: 中南大学材料科学与工程学院, 2014: 55-58.

OUYang Hui. Influence of Zn/Mg ratio on quench sensitivity of Al-Zn-Mg-Cu alloy[D]. Changsha: Central South University. School of Materials Science and Engineering, 2014: 55-58.

[8] 王雷. Al-9.0Zn-1.5Mg-XCu合金微结构、力学性能及淬火敏感性研究[D]. 长沙: 中南大学材料科学与工程学院, 2014: 45-47.

WANG Lei. Study on Microstructures, mechanical properties and quench sensitivity of Al-9.0Zn-1.5Mg-XCu alloys[D]. Changsha: Central South University. School of Materials Science and Engineering, 2014: 45-47.

[9] 陈慧. Al-Zn-Mg-Cu 合金的淬火敏感性及时效析出行为研究[D]. 长沙: 中南大学材料科学与工程学院, 2013: 34-37.

CHEN Hui. The research of quench sensitivity and age precipitation behavior of A1-Zn-Mg-Cu alloys[D]. Changsha: Central South University. School of Materials Science and Engineering, 2013: 34-37.

[10] Lim S T, Yun S J, Nam S W. Improved quench sensitivity in modified aluminum alloy 7175 for thick forging applications[J]. Materials Science and Engineering A, 2004, 371(1/2): 82-90.

[11] DENG Yunlai, WAN Li, ZHANG Yunya, et al. Influence of Mg content on quench sensitivity of Al-Zn-Mg-Cu aluminum alloys[J]. Journal of Alloys and Compounds, 2011, 509(13): 4636-4642.

[12] 伊琳娜, 汝继刚. 7B04 铝合金锻件淬透性的研究[J]. 航空材料学报, 2003(Z1): 288.

YI Linna, RU Jigang. A study on quenching degree of 7B04 aluminum alloy forging[J]. Journal of Aeronautical Materials, 2003(Z1): 288.

[13] 熊柏清, 李锡武, 张永安, 等. 新型高强韧低淬火敏感性Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr合金[J]. 中国有色金属学报, 2009, 19(9): 1539-1547.

XIONG Baiqing, LI Xiwu, ZHANG Yongan, et al. Novel Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr alloy with high strength high toughness and low quench sensitivity[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1539-1547.

[14] 张新明, 邓运来, 张勇, 等. 测量铝合金材料淬透深度的装置及方法: 中国, 200710034410.8[P]. 2007-08-08.

ZHANG Xinming, DENG Yunlai, ZHANG Yong, et al. Measurement device and method of quenched depth for aluminum alloy: China,200710034410.8[P]. 2007-08-08.

[15] 刘胜胆, 张新明, 黄振宝, 等. 7055 铝合金的淬火敏感性研究[J]. 中南大学学报(自然科学版), 2006, 37(5): 846-849.

LIU Shengdan, ZHANG Xinming, HUANG Zhenbao, et al. Quench sensitivity of 7055 aluminum alloy[J]. Journal of Central South University (Science and Technology), 2006, 37(5): 846-849.

[16] TANG Jianguo, CHEN Hui, ZHANG Xinming, et al. Influence of quench-induced precipitation on aging behavior of Al-Zn-Mg-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1255-1263.

[17] Buha J, Lumley R N, Crosky A G. Secondary aging in an aluminum alloy 7050 Secondary aging in an aluminum alloy 7050[J]. Materials Science and Engineering A, 2008, 492: 1-10.

[18] Godard D, Archambault P, Aeby-Gautier E, et al. Precipitation sequences during quenching of the AA7010 alloy[J]. Acta Materialia, 2002, 50 (9): 2319-2329.

(编辑 赵俊)

收稿日期:2014-03-26;修回日期:2014-07-17

基金项目(Foundation item):国家重点基础研究发展计划(973计划)项目(2012CB619500)(Project (2012CB619500) supported by the National Basic Research Program of China (973 Program))

通信作者:张新明,教授,博士生导师,从事材料科学与工程研究;E-mail:zhang_cn@yahoo.cn