Trans. Nonferrous Met. Soc. China 24(2014) 2877-2882

Effects of tribological behavior of DLC film on micro-deep drawing processes

Chun-ju WANG1,2,3, Chuan-jie WANG1,2, Bin GUO1,2,3, De-bin SHAN1,2,3

1. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

3. Key Laboratory of Micro-systems and Micro-structures Manufacturing (HIT), Ministry of Education, Harbin Institute of Technology, Harbin 150001, China

Received 8 July 2013; accepted 12 May 2014

Abstract: To decrease the size effects of friction in microforming, three kinds of surface coatings, such as diamond-like carbon (DLC), TiN and MoS2, were deposited on surfaces of dies with plasma based ion implantation and deposition (PBII & D) method and magnetron sputtering technique, respectively. The tribological behavior of surface coatings was analyzed considering plastic deformation of specimen at contact interface. The analyses indicate that there is a lower coefficient of friction (COF) and a high wear resistance under the condition of large strain/stress when using the DLC film. The graphitization of DLC film occurs after 100 times of tests. The mechanism of graphitization was analyzed considering energy induced by friction work. The effects of DLC film properties on qualities of micro-deep drawn parts were investigated by analyzing the reduction of wall thickness, etc. The results indicate that DLC film is very helpful for improving the qualities of the micro-parts.

Key words: micro-deep drawing; diamond-like carbon film; tribological behavior; micro-cups; graphitization

1 Introduction

Microforming process is very suitable for the massive production of micro-parts used in micro-electro-mechanical systems (MEMS) [1]. With the miniaturization of micro-parts, size effects of friction occur obviously when a liquid lubricant is applied [2,3]. For example, the friction factor increases from 0.02 in the case of the d4.0 mm specimen up to 0.15 for the smaller specimen of the d1.0 mm in micro-extrusion [4]. Because of the size effects, the micro-deep drawing process is different from the macro-deep drawing processes, and the friction has an obvious effect on the plastic deformation behaviors of thin sheet in micro-deep drawing processes [5,6]. For its excellent tribological properties [7], the diamond-like carbon (DLC) film gains more and more attention both in macro-forming and microforming processes. Carbon thin film was applied to friction-reducing and wear protection in metal forming [8-10]. For example, it was found that it was effective to reduce friction under dry friction condition of DLC film in wire drawing process [11]. The best results for the lubricant of Si-DLC film was at temperature of 700 °C in warm metal forming [12]. In microforming, it becomes difficult for DLC film to deposit on the inner surface of female die cavities due to their small dimensions [13]. A DLC micro-film coating method was proposed by making use of argon gas [14]. The results by TAKATSUJI et al [15] showed that the maximum extrusion force decreased from 32 kN for uncoated die to 25 kN for the DLC-spatter-coated die due to its lower coefficient of friction (COF), which was also much lower than that for CrN coated die and TiN coated die. Using DLC coated blank holders and dies, micro-cups with high limit drawing ratio (LDR) were manufactured successfully because of low friction [16-18]. The micro bending tests showed that the wear resistance of DLC film was excellent [19]. The nano-laminated DLC film was applied to improving the coated tool life in dry micro stamping [20]. However, the wear mechanism of DLC film in microforming processes was not investigated, and the effects of tribological behavior on the qualities of micro-parts should be studied in details.

In this work, the tribological behaviors of DLC, TiN and MoS2 films were evaluated in strip drawing tests. The COF of films was measured, and the wear resistance ability was analyzed. Considering friction work, the graphitization of DLC film was studied with Raman spectra. In micro-deep drawing process, DLC film coated dies were applied to manufacturing micro-cup of 1.1 mm in diameter by using T2 copper thin sheet with 40 μm in thickness. The qualities of micro-cups with DLC film coated dies, such as surface quality, reduction of thickness, accuracy of inner diameter, were analyzed by comparison with that obtained by polyethylene (PE) film coated dies.

2 Experimental

Since T2 copper could be deformed under high contact pressure in micro-deep drawing, the tribological behaviors are different from the rigid contact in traditional ball-on-disk tests. A new COF evaluation method was developed with strip drawing tests between two opposing flat die surfaces which were wider than the strip [21]. The tests were carried out using a precision tension instrument. Then, the COF can be calculated by Eq. (1) based on the Coulomb’s law.

μ=F/(2N) (1)

where μ is COF, F is friction force and N is normal force loaded by two punches. The tool steel JIS-SKD11 was selected as punch material, and the hardness was treated to HRC 60. The contact punch surface was polished to surface roughness Ra of 0.1 μm, which was helpful for the deposition of surface film. The TiN and DLC films on die surface were deposited in PBII&D facility, and MoS2 film was prepared by magnetron sputtering technique. The parameters used in surface film deposition are shown in Table 1.

The surface topography of DLC film was observed by SEM (HITACHI, S-4300). The evolution of the sp3 and sp2 phases was analyzed by Raman spectra (JY, HR800) with excitation wavelength of 532 nm at power of 0.1 mW.

A serial of micro-deep drawing experiments were carried out using the blanking-deep drawing multiple operation die [17,18]. The diameters of blanked specimen D and formed micro-cup d were 2.0 mm and 1.1 mm, respectively. Then, the limited drawing ratio (LDR, D/d) was 1.8. The punch load was obtained directly by a small precision sensor embedded in the die.

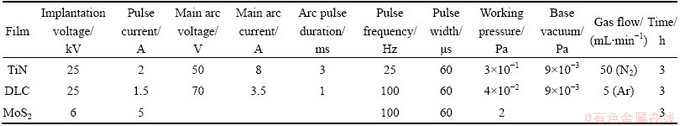

Table 1 Parameters for deposition of surface films

Fig. 1 Coefficient of friction with different films

3 Results and discussion

3.1 Tribological properties of surface coatings

Using the strip drawing experiments, the COF was obtained under various lubricant conditions shown in Fig. 1. The COF is decreased from 0.30 for no surface coating to 0.21, 0.15 and 0.13 for DLC, MoS2 and TiN film with specimen of 1.0 mm in width, respectively. The reduction amounts of COF are 30%, 50% and 56.7% of that for no surface coating. This means that the surface coating is very helpful for friction-reducing. When the width of specimen is changed from 1.0 mm up to 2.0 mm, the COF is almost the same as that for no surface coating, DLC and TiN film. This indicates that size effects of friction do not occur, and the surface films, such as DLC and TiN film, can be used in microforming for friction-reducing. At the same time, it is found that the COF obtained by the strip drawing test is a little higher than that obtained by ball-on-disk test as shown in Ref. [17]. The reason may be that the plastic deformation of specimen occurs at the contact interface under high contact pressure.

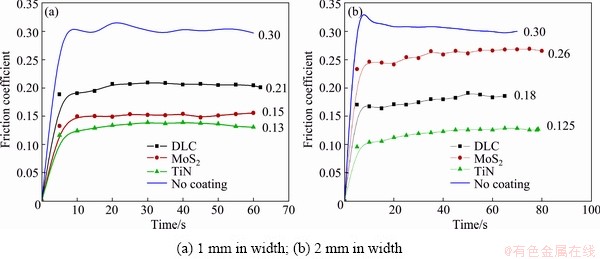

After about 100 times of tests, the surface topographies of coatings were observed with SEM as shown in Fig. 2. A lot of chippings appear on the surface of MoS2 film, and the TiN film is better than MoS2 film. It is very interesting that there is no cracking or chipping on the surface of DLC film, which means that the DLC film can endure larger strain/stress. Based on these results, DLC film is adapted to deposit on the die used in micro-deep drawing.

Fig. 2 SEM photographs of surface coating after tests

3.2 Wear mechanism of DLC film

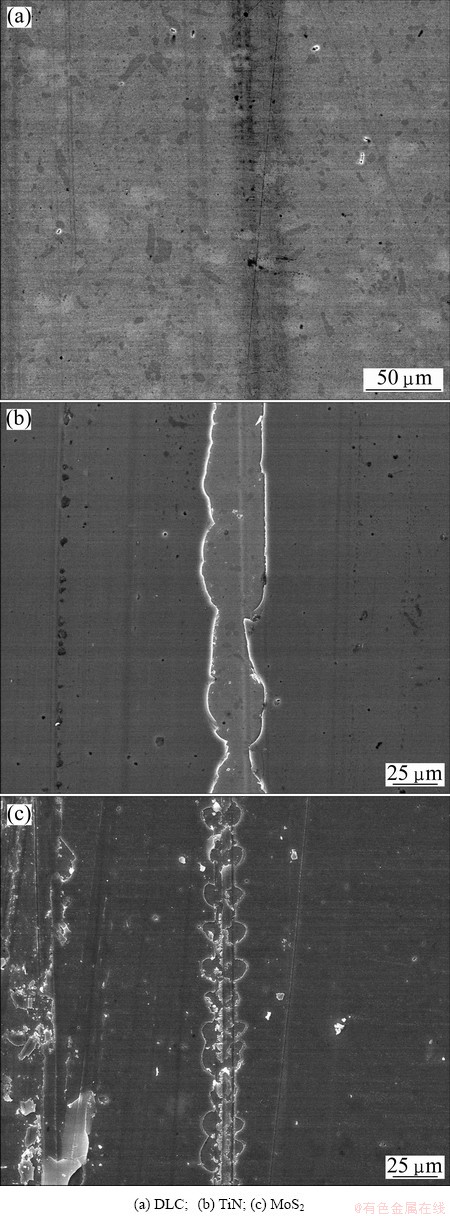

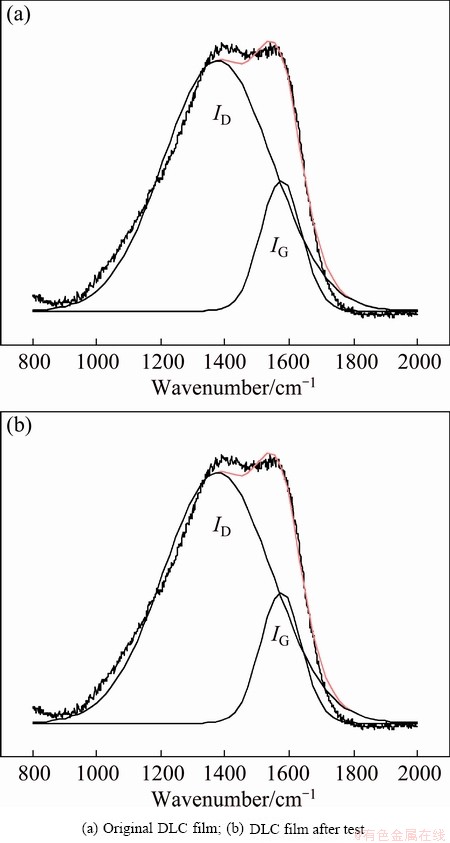

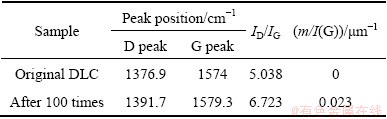

To evaluate the abrasion of DLC film in strip drawing, a series of 532 nm Raman spectra were obtained before and after 100 times of tests. The curves are fitted with Gaussians equation for the G and D peaks (Fig. 3), and the parameters, such as D peak, G peak and ratio between intensity of the D peak and G peak, are obtained in Table 2. After 100 times of tests, the peak frequency of D peak and G peak becomes large, and the ratio of ID/IG increases at the same time. These results indicate that the phase transformation of DLC film occurs obviously. For the energy induced by the friction, some sp3 bonds are changed to sp2 bonds. Since the plastic deformation occurs in the surface layer of copper specimen, the energy due to the friction at the contact area is much larger than that in rigid contact. The friction contributes to the activation energy of the transformation from sp3 bonds to sp2 bonds. As a result, the graphitization of DLC film occurs clearly [22]. Interestingly, the ratio of the slope m of the fitted linear background to intensity of the G peak, m/I(G), becomes large after 100 times of tests. As we know, the ratio m/I(G) can be used to evaluate the content of hydrogen in DLC film. This means that the DLC film still contains a certain number of hydrogen atoms which are not in the form of C—H bonds.

Fig. 3 Raman spectra of DLC film

Table 2 Analysis results of Raman spectra

3.3 Effects of tribological behavior on micro-deep drawing

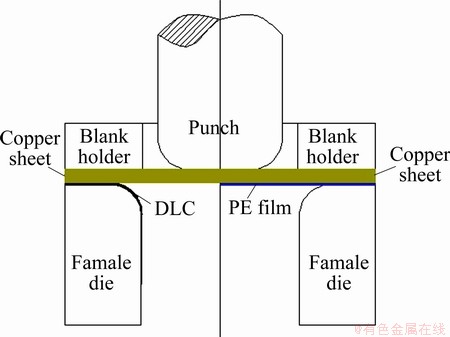

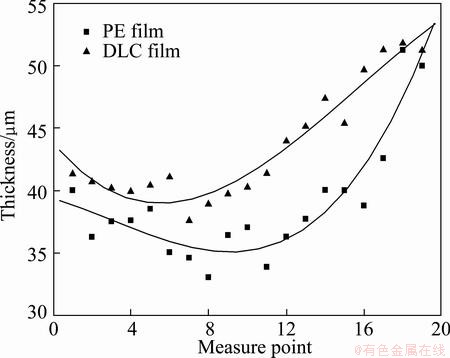

Since there were obvious size effects of friction when lubricant oil was applied, two kinds of solid films, DLC film and PE film, were applied to micro-deep drawing as shown in Fig. 4 due to their lower COF. The DLC film was deposited on the female die and blank holder by PBII&D method with parameters shown in Table 1, and a commercial PE film of 5 μm in thickness was chosen and put directly between copper sheet and female die, which was blanked and deep drawn together with copper sheet during the moving down of punch. Micro-cups were successfully deep drawn with DLC film and PE film. The SEM photographs of micro-cups show that no wrinkles in the rim occurs with DLC coated female die as shown in Fig. 5(a). However, there are many wrinkles in the rim when PE film is applied as shown in Fig. 5(b). Due to the force induced by friction and plastic deformation, obvious tensile deformation occurs at the wall of micro-cup, which can lead to the breakage at the bottom corner of micro-cup for the reduction of wall thickness. The thickness of wall at bottom corner of micro-cup was measured at the points as shown in Ref. [18] using a confocal laser scanning microscope (Olympus, OLS3000) as shown in Fig. 6. The reduction of wall thickness of micro-cup formed using DLC film coated die is lower than that using PE film. The reason is that the PE film can be easily accumulated at the corner of female die during the micro-deep drawing process for its lower strength, and it becomes difficult for T2 copper sheet to be pulled into female die. As a result, the thickness of wall decreases under the relative small clearance. At the same time, the accumulation of PE film leads to the wrinkles in the rim. It also has an obvious effect on the inner diameter of micro-cup [18]. The inner diameters of micro-cups are 1.091 mm and 1.088 mm for the DLC film and PE film, respectively. The measured value is different from the designed value of 1.1 mm. The error increases from 9 μm for DLC film to 12 μm for PE film.

Fig. 4 Lubrication of DLC film and PE film [18]

Fig. 5 Micro-cups obtained under different lubrication conditions

Fig. 6 Thickness of sheet near bottom corner of micro-cup

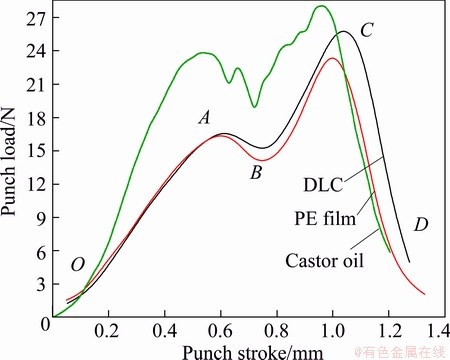

Figure 7 shows the punch load in micro-deep drawing with thin T2 copper sheet under different lubrication conditions. The maximum punch load for lubrication with DLC film is approximately 8.7% lower than that of lubrication with castor oil, which is close to that of lubrication with PE film. This means that DLC film possesses lower COF in microforming.

Fig. 7 Punch load-stroke of micro-deep drawing

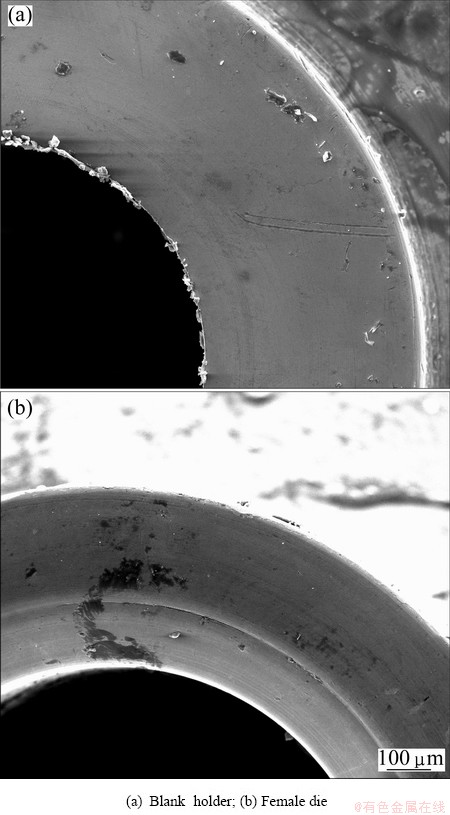

Fig. 8 DLC film on micro-die surface after tests

After about 100 times of tests, the DLC film on blank holder and female die were observed using SEM as shown in Fig. 8. It can be seen that there are no scratch marks on the surface of DLC film, which means that DLC film possesses strong adhesion with substrate and excellent wear resistance to endure high strain/stress condition in microforming. At the same time, we notice that there are many debris of copper sheet left on the contact surface of blank holder and female die after micro-deep drawing. In the following deep drawing, the debris may lead to stress concentration. Then, the DLC film can be easily worn under the higher stress.

4 Conclusions

1) The strip drawing tests show that DLC film possesses lower COF independent of the specimen dimensions, and can endure high strain/stress in microforming due to the strong adhesion with substrate and excellent wear resistance.

2) After about 100 times of tests, the ratio of ID/IG increases clearly, which means that the graphitization of DLC film occurs.

3) The micro-cup of high quality was successfully deep drawn with DLC coated die. After micro-deep drawing tests, there are no scratch marks on the surface of DLC film.

Acknowledgments

The authors would like to thank Prof. Xiu-bo TIAN for the help of DLC film deposition.

References

[1] VOLLERTSEN F, HU Z, SCHULZE N H, THEILER C. State of the art in micro forming and investigations into micro deep drawing [J]. Journal of Materials Processing Technology, 2004, 151(1-3): 70-79.

[2] ENGEL U. Tribology in microforming [J]. Wear, 2006, 260(3): 265-273.

[3] GONG Feng, GUO Bin, WANG Chun-ju, SHAN De-bin. Size effect on friction of C3602 in cylinder compression [J]. Tribology Transactions, 2010, 53(2): 244-248.

[4] ENGEL U, ECKSTEIN R. Microforming-from basic research to its realization [J]. Journal of Materials Processing Technology, 2002, 125-126: 35-44.

[5] SAOTOME Y, YASUDA K, KAGA H. Microdeep drawability of very thin sheet steels [J]. Journal of Materials Processing Technology, 2001, 113(1-3): 641-647.

[6] MANABE K, SHIMIZU T, KOYAMA H, YANG M, ITO K. Validation of FE simulation based on surface roughness model in micro-deep drawing [J]. Journal of Materials Processing Technology, 2008, 204(1-3): 89-93.

[7] KLOCKE F, MAβMANN T, BOBZIN K, LUGSCHEIDER E, BAGCIVAN N. Carbon based tool coatings as an approach for environmentally friendly metal forming processes [J]. Wear, 2006, 260(3): 287-295.

[8] WANG Yong-xin, LI Jin-long, WANG Li-ping, CHEN Jian-min, XUE Qun-ji. Tribological performances of graphite-like carbon films coupled to different ceramics in ambient air and water [J]. Tribology Transactions, 2013, 56(3): 333-341.

[9] ARUP G, KAUSTAV S, DAIRENE U, DOUGLAS G M, ROBERT J Z, STEVEN J S. Friction, wear, and surface film formation characteristics of diamond-like carbon thin coating in valvetrain application [J]. Tribology Transactions, 2011, 54(1): 104-114.

[10] WANK A, REISEL G, WIELAGE B. Behavior of DLC coating in lubricant free cold massive forming of aluminum [J]. Surface and Coatings Technology, 2006, 201(3-4): 822-827.

[11] MURAKAWA M, JIN M, HAYASHI M. Study on semidry/dry wire drawing using DLC coating dies [J]. Surface and Coatings Technology, 2004, 177-178: 631-637.

[12] REISEL G, STEINHAUSER S, WIELAGE B. The behaviour of DLC under high mechanical and thermal load [J]. Diamond and Related Materials, 2004, 13(4-8): 1516-1520.

[13] WANG Chun-ju, GUO Bin, SHAN De-bin. Properties of DLC film deposited on mould with micro-cavity used in microforming [J]. Integrated Ferroelectrics, 2012, 136(1): 35-42.

[14] YANG X D, SAITO T, NAKAMURA Y, KONDA Y, OHTAKE N. Mechanical properties of DLC films prepared inside of micro-holes by pulse plasma CVD [J]. Diamond and Related Materials, 2004, 13(11-12): 1984-1988.

[15] TAKATSUJI N, DOHDA K, MAKINO T, YOSHIMURA T. Friction behavior in aluminum micro-extrusion [C]//AZUSHIMA A. Proceeding of International Conference on Tribology in Manufacture Processes. Yokohama, Japan: SUBARU Planning, 2007: 157-162.

[16] HU Z, SCHUBNOV A, VOLLERTSEN F. Tribological behaviour of DLC-film and their application in micro deep drawing [J]. Journal of Materials Processing Technology, 2012, 212(3): 647-652.

[17] GONG Feng, GUO Bin, WANG Chun-ju, SHAN De-bin. Micro deep drawing of micro cups by using DLC film coated blank holders and dies [J]. Diamond and Related Materials, 2010, 20(2): 196-200.

[18] WANG Chun-ju, GUO Bin, SHAN De-bin, BAI Xin-mei. Experimental research on micro-deep drawing processes of pure gold thin sheet using DLC-coated female die [J]. The International Journal of Advanced Manufacturing Technology, 2013, 67(9-12): 2477-2487.

[19] FUJIMOTO K, YANG M, HOTTA M, KOYYAMA H, NAKANO S, MORIKAWA K, CAIRNEY J. Fabrication of dies in micro-scale for micro-sheet metal forming [J]. Journal of Materials Processing Technology, 2006, 177(1-3): 639-643.

[20] AIZAWA T, ITOH K, IWAMURA E. Nano-laminated DLC coating for dry micro-stamping [J]. Steel Research International, 2010, 81: 1169-1172.

[21] GUO Bin, GONG Feng, WANG Chun-ju, SHAN De-bin. Size effect on friction in scaled down strip drawing [J]. Journal of Materials Science, 2010, 45(15): 4067-4072.

[22] WANG Chun-ju, GUO Bin, SHAN De-bin, BAI Xin-mei. Tribological behaviors of DLC film deposited on female die used in strip drawing [J]. Journal of Materials Processing Technology, 2013, 213(3): 323-329.

DLC薄膜摩擦行为对微拉深工艺的影响

王春举1,2,3,王传杰1,2,郭 斌1,2,3,单德彬1,2,3

1. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

3. 哈尔滨工业大学 微系统与微结构制造教育部重点实验室,哈尔滨 150001

摘 要:为了降低微成形中的摩擦尺寸效应,采用基于离子注入、沉积法和磁控溅射技术在模具表面分别镀上3种涂层(DLC、TiN和MoS2)。考虑试样在接触面的塑性变形,分析了表面涂层的摩擦行为。分析表明:当使用DLC涂层时,摩擦因数较低,并且在大应力应变条件下具有较高的抗磨损性能。当进行100次摩擦实验后,DLC薄膜出现石墨化。从摩擦功影响而导致能量降低的角度分析了石墨化机理。通过减小壁厚等研究了DLC薄膜的性能对微拉深件质量的影响。结果表明,DLC薄膜有助于改善微型构件的质量。

关键词:微拉深;DLC薄膜;摩擦行为;微型杯件;石墨化

(Edited by Hua YANG)

Foundation item: Projects (51375113, 50805035) supported by the National Natural Science Foundation of China

Corresponding author: Chun-ju WANG; Tel/Fax: +86-451-86418640; E-mail: cjwang1978@hit.edu.cn

DOI: 10.1016/S1003-6326(14)63421-X