文章编号:1004-0609(2016)-07-1531-07

高压辊磨对金矿石堆浸效果的影响机理

唐 远,印万忠,马英强,迟晓鹏,黄发兰

(福州大学 紫金矿业学院,福州 350116)

摘 要:采用常规颚式破碎机和高压辊磨机破碎设备,开展两种不同破碎方式下金矿石柱浸试验,研究不同破碎方式对较粗粒级金矿石堆浸效果的影响,并结合破碎产品特性及显微分析技术,进一步探究高压辊磨方式在金矿石处理中的作用机理。结果表明:高压辊磨机较常规颚式破碎机产品粒度略细,颗粒表面裂纹更加丰富、堆浸体系饱和含水率较高,高压辊磨机对改善堆浸体系渗透效果和提高浸出率的效果明显;在相同条件下,试验金矿石浸出率提高约3.5%~6.8%,浸出剂耗量减少3.2%~11.3%。

关键词:破碎方式;高压辊磨机;堆浸;微裂纹;饱和含水率

中图分类号:TF19 文献标志码:A

我国有色矿产资源贫矿多,富矿少,小型复杂共生矿多,这些特点在黄金矿山也尤为突出。堆浸法是国内外从低品位金矿石中回收金的一种较为成熟工艺,具有成本低、污染小、操作简单和适应性好等优点[1-3]。堆浸工艺不仅大大提高金矿资源的综合利用率,拓宽矿产资源的可利用范围,而且明显简化常规工艺矿石准备过程,省去了高耗能的磨矿作业[4]。但堆浸工艺并非万能,不是所有的金矿都适合采用堆浸工艺,主要受金赋存状态、矿石氧化程度、裂隙和孔洞等的发育情况等诸多因素的影响。高压辊磨机作为一种高效的破碎设备,已在黑色金属、有色金属和无机非金属等矿山加以应用[5-7],具有单位破碎能耗低、处理能力大、占地面积少等优点[8-11]。借助高效粉碎方式,在原处理工艺基础上,进一步降低破碎能耗,提高金属回收率成为现阶段研究工作的重点。针对该问题,国内外学者开展了一些研究工作。

KODALI等[12]采用X射线显微断层扫描技术(XMT),分析不同破碎方式下氧化铜矿石的柱浸效果机理,指出高压辊磨产品形成的微裂纹,加快了溶浸液透过微裂纹并溶解铜矿物的速度,明显提高了铜回收率。PATZELT等[13]以石英脉型和矽卡岩型金矿石破碎产品的粒度分布及邦德(Bond)球磨功指数为切入点,指出高压辊磨方式能耗低、产品细粒级含量高,对搅拌浸出有利。KELLY等[14]得出了较稳定的破碎分布函数,定量分析了大量的晶界微裂纹的产生机理。国内学者也开展了大量工作,谢洪珍等[15]通过柱浸实验探究高压辊磨机对金矿堆浸效果的影响,分析单体解离度和产品微裂纹的作用。这些针对高压辊磨机的应用效果研究,可为高压辊磨方式在低品位金矿石堆浸中的影响及作用机理的研究工作提供有力的指导和借鉴。相比常规破碎方式只单纯针对较大颗粒的机械剪切、劈裂、击碎等作用效果来说,聚集于有限空间中的颗粒间相互挤压传递应力造成的粉碎显得更有优势。

综上所述,目前针对高压辊磨方式对金矿石堆浸效果影响机理的系统研究还较缺乏,本文作者首先以常规颚式破碎方式产品确定了实验室最佳柱浸试验条件,再针对不同破碎方式下大于0.15 mm粒级产品,开展实验室微型和小型柱浸试验,并研究破碎方式对堆浸体系中金的溶解和浸出液渗透过程的影响,即对金矿石堆浸效果的影响机理进行详细的探究,为实现高压辊磨方式在金矿石堆浸工艺中的应用奠定了基础。

1 实验

1.1 矿样性质和制备

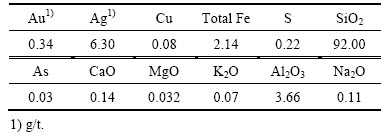

试验样取自闽西某地,矿石中金属矿物以褐铁矿、黄铁矿为主,还有少量铜蓝和蓝辉铜矿;脉石矿物绝大多数为石英,还有少量地开石和明矾石。金含量较低,主要以自然金形式存在,占86.44%,适宜通过氰化浸出法处理。原矿主要化学成分分析结果见表1。

表1 试样化学成分分析

Table 1 Chemical composition of samples (mass fraction, %)

原矿采用PEX-150×250和XPC-60×100两种型号的颚式破碎机及20 mm圆孔筛组成的闭路破碎流程进行粗、中碎,混匀后再分别采用CLM-25-10型高压辊磨机和PEF-60×100型颚式破碎机进行全开路细碎,其中高压辊磨机辊面压力为5.5 N/mm2,工作辊间距4~7 mm,辊子转速0.4 m/s,破碎产品分成0.15~6.70 mm和大于6.70 mm粒级作为试验样。

1.2 柱浸试验方案

取一定质量的石灰与0.15~6.70 mm粒级试验样混匀后,放入直径为50 mm的实验室微型浸出柱内(为避免装矿时产生物料偏析,采用分层混匀装柱方式),调节恒流泵流量为10 L/(m2·h),先用清水喷淋至流出液体的pH值为10.5~11后,加入配制好的适宜浓度的氰化钠溶液进行开路浸出,定期取样化验,浸出完成后化验浸出渣品位。大于6.70 mm粒级试样则在直径为160 mm的小型浸出柱内进行闭路浸出,浸出条件与微型浸出柱相同。

2 结果与讨论

2.1 高压辊磨方式对堆浸体系粒度分布的影响

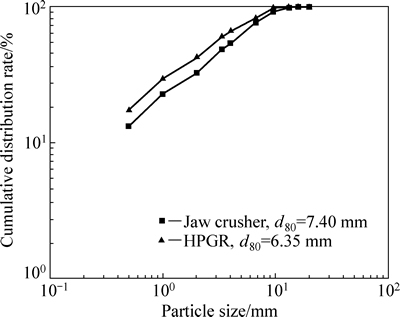

堆浸体系的颗粒产品越细,浸出剂与解离金颗粒直接接触的几率越大,但粒度过细会导致矿堆的气液渗透能力降低,阻碍浸出反应的进行、减慢浸出富液的流出速率。对两种破碎方式下大于0.15 mm较粗粒级破碎产品进行粒度筛析,粒度分布结果如图1所示。

由图1可看出,与常规颚式破碎产品相比,高压辊磨产品粒度较细。常规颚式破碎机产品的 d80=7.40 mm,比高压辊磨机产品 d80 >16.5%,表明高压辊磨机破碎比更大、粉碎效率更高,相比常规破碎方法其产品力学性质弱,进一步粉碎所需能量少。为进一步描述该部分产品的粒度特性,采用偏差系数 Kd描述物料均匀程度[16],Kd的计算公式如下:

(1)

(1)

式中:wi为各粒级所占的质量分数,%;di为各粒级平均直径,mm;D 为加权算术平均粒度,mm。

图1 不同破碎方式粗粒级产品的粒度分布

Fig. 1 Particle size distribution of coarse particles from different comminuting methods

根据式(1)计算出常规颚式破碎产品偏差系数 Kd 较高压辊磨产品偏差系数略小,表明高压辊磨方式产品的粒度波动略大,在中间粒级和细粒级的集中程度较高。高压辊磨机产品相对较细且均匀,浸出剂到达金矿物表面的路径较短,且在矿堆中渗流时能均匀分布,溶解金矿物后的富液扩散释放距离也较短,可以缩短浸出时间,同时,堆浸体系的稳定性也较好,对金矿堆浸有利。

2.2 高压辊磨方式对矿堆含水率的影响

堆浸体系含水率对矿堆内气液两相的运移状态具有重要影响[17],在金矿堆浸中常通过测定体系饱和含水率来反映浸出稳定时的气液渗流特性。浸出反应完成后,矿堆内部溶质主要借助于溶液渗流运出,矿堆体系饱和含水率越大,单位时间内溶质运移量越大、扩散速度越快,越利于富液的迁移。矿堆饱和含水率不仅与矿石粒度、矿石的矿物组成有关,而且还与物料表面等物理特性等有关。对不同破碎方式矿样饱和含水率的测定,不仅能反应矿堆体系的粒度特性,还能间接说明颗粒表面裂纹数量及裂纹内部连通特性。

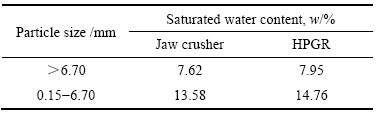

分别选取大于6.70 mm和0.15~6.70 mm粒级质量为m的混匀试样放入浸出柱内,加质量为m1的水充分浸泡48 h后将水放出,测定放出水的质量为m2,饱和含水率η按公式(2)计算。分别重复3次测定两种破碎方式不同粒级试样的含水率,并计算出各粒级的平均含水率,其结果列于表2。

(2)

(2)

表2 堆浸体系饱和含水率的测定结果

Table 2 Saturated water content result of heap leaching

由表2中两种不同破碎方式下的矿堆饱和含水率结果可知,堆浸体系粒度越小,饱和含水率越高,且大于6.70 mm和0.15~6.70 mm粒级高压辊磨机破碎产品饱和含水率分别比常规颚式破碎机的高4.33%和8.69%。根据粒度分布结果,在相同粒度范围内,高压辊磨机产品的粒度细,产品持液能力更强。在浸出过程中,矿堆含水率越高,溶液渗透率越大,且溶浸剂与矿石充分接触,利于浸出反应的进行。高压辊磨方式产品丰富且内部连通的微裂纹,对于液体大量渗透到颗粒内部至关重要,粒度越大,内部裂纹延伸到颗粒表面的难度就越大或只形成连通性差的裂纹体系。高压辊磨机破碎方式能通过改变破碎物料粒度和微裂纹等特性,改善矿堆饱和含水率并保持在较高的合理水平,促进矿堆内溶液渗流、加快溶质迁移过程,提高矿堆浸出速率。

2.3 高压辊磨方式对产品微裂纹特性的影响

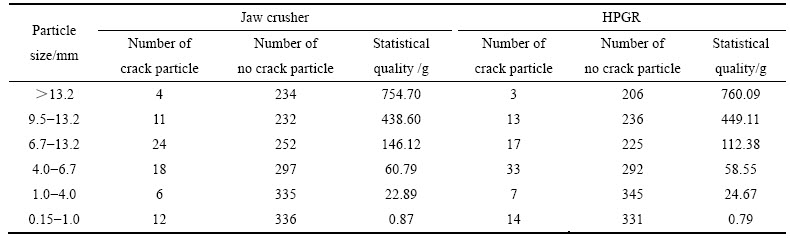

当堆浸体系气液渗透能力一定时,堆浸效果的好坏则仍取决于浸出剂的溶解效果,溶解速度变慢,必然影响堆浸的浸出效果。借助蔡司SteREO Discovery体视显微镜分析技术,对一定质量是否含有表观微裂纹的颗粒数量进行了定量统计,统计结果列于表3,主要粒级代表性颗粒的微裂纹见图2。

由表3统计数据可知,两种破碎方式产品4.0~13.2 mm粒级含微裂纹颗粒数目均较多,大于13.2 mm粒级大部分为未粉碎物料(在高压辊磨机内,由于开路破碎的“边缘效应”造成部分粗粒物料从辊子边缘下落;而常规颚式破碎机则由于动颚回缩运动时未受挤压而直接排出),因此,该粒级含裂纹的颗粒极少。相同粒级,高压辊磨机产品表面含裂纹的颗粒数目所占的比例几乎全都高于常规颚式破碎机。裂纹数量越多越有利于浸出,但实际发现粒度过大时,两种破碎方式颗粒的微裂纹在数量上的差别不大,因此,过粗粒级金矿石浸出效果差异将不明显。若能够解决高压辊磨方式开路破碎工艺中的“边缘效应”问题(如增加辊子宽径比),粗颗粒也能受到静压力作用,理论上将有助于堆浸金浸出率的提高。

图2(a)、(b)和(c)所示分别为各粒级常规颚式破碎方式产品,(d)、(e)和(f)所示分别为各粒级高压辊磨方式产品。从图2中可看出,两种破碎方式各粒级产品中,高压辊磨方式产品颗粒表面微裂纹数量明显高于常规颚式破碎方式产品。由于试样中石英含量达90%以上,故在体视显微镜下辨别的粗颗粒表面几乎全是石英,初判该裂纹均属于晶内裂纹[18]。从整体上看,高压辊磨机的静压破碎方式,能在产品中形成丰富的微裂纹,使颗粒的比表面积和单位孔体积均显著增加,加大浸出过程中接触面积和渗透率,使氰化浸出反应能更快的从多个方向同时进行,避免与其他矿物的络合反应,从而达到降低浸出剂的消耗、提高浸出效果的目的。

表3 裂纹颗粒统计结果

Table 3 Statistical results of crack particles

图2 破碎产品颗粒裂纹体视显微镜图

Fig. 2 Stereomicroscopy images of particles micro-cracks from broken products:

2.4 高压辊磨方式对金浸出率的影响

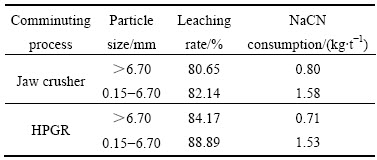

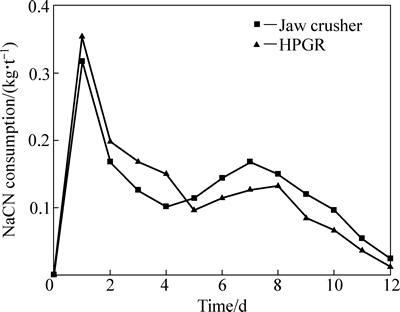

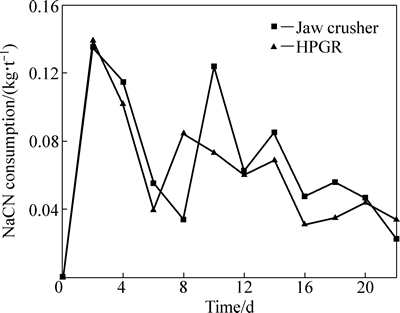

针对试样采用实验室柱浸试验,探究两种破碎方式对金矿堆浸体系浸出率的影响规律。大于6.70 mm粒级小型柱浸浸出周期为22 d,0.15~6.70 mm粒级微型柱浸浸出周期为12 d,浸出结束后用清水喷淋,得到的金浸出率结果和氰化钠消耗量见表4,柱浸氰化钠消耗量与时间的关系见图3和4。

由表4中可知,在相同浸出条件下,高压辊磨方式较常规颚式破碎方式0.15~6.70 mm粒级试样金浸出率提高6.75%,浸出剂的耗量下降约3.2%,大于6.70 mm粒级试样金浸出率提高3.52%,浸出剂的耗量下降约11.3%,即金矿石高压辊磨机破碎产品的柱浸浸出率高于常规颚式破碎机且能明显降低浸出剂用量。

表4 柱浸试验结果

Table 4 Results of column leaching test

图3 微型柱浸氰化钠耗量与时间关系

Fig. 3 Relationship between NaCN consumption and leaching time in micro-column leaching

图4 小型柱浸氰化钠耗量与时间关系

Fig. 4 Relationship between NaCN consumption and leaching time in mini-column leaching

根据图3中氰化钠耗量与浸出时间的关系,得到以下规律:在堆浸体系的浸出反应初期,随着浸出剂的进入,矿堆中完全裸露的较易浸出金优先溶解,消耗大量浸出剂,随着完全裸露金数量的减少,氰化钠消耗的速度逐渐减慢。在反应前4 d,由于高压辊磨方式产品丰富的表面裂纹,使产品中裸露或半裸露金的数量増多,加快了浸出剂向颗粒内部渗透的速率,氰化钠用量较常规破碎方式略多。从第5 d开始,常规破碎方式产品浸出剂消耗开始呈上升趋势,说明易接触溶解的金已基本溶解完全,浸出剂开始作用于较难浸出部分的金或与其他金属氧化物离子发生络合,而此时高压辊磨机产品对浸出剂的消耗仍呈下降趋势,表明高压辊磨方式产生了足够多的颗粒裂纹,浸出反应仍然较易进行,对多余浸出剂的消耗较少。图4中小型柱浸氰化钠耗量与时间关系反应的结果与图3基本相同,整体来看,高压辊磨方式产品的浸出反应较易发生,浸出剂的消耗较少,且浸出完成时间短。图4与图3基本相同。柱浸试验结果表明,高压辊磨方式产品的浸出反应较易发生,浸出剂的消耗较少,且浸出完成时间短。

3 结论

1) 与常规颚式破碎方式相比,高压辊磨方式具有破碎比大、破碎效率高、产品粒度细等特点,可在保证堆浸体系稳定性的基础上,使浸出剂在矿堆中能均匀分布,并缩短浸出反应路径,能加快金矿物的溶解及其向矿堆体系的扩散、迁移。

2) 高压辊磨方式产品具有相对丰富且内部连通的裂纹,可以起到改善并保持矿堆饱和含水率在较高的合理水平的作用,从而优化矿堆内溶液渗流、加快溶质迁移过程,对提高堆浸体系的浸出速率有利。

3) 两种不同破碎方式下各粒级产品的显微分析结果表明,高压辊磨方式产品微裂纹在数量上占优,增大了颗粒的比表面积和单位孔体积,可使浸出过程的反应接触面和自发渗透溶解速率均显著增加,能明显提高金浸出率。

4) 该金矿石高压辊磨方式产品的柱浸浸出率可提高约3.5%~6.8%,浸出剂的消耗量约减少3.2%~11.3%,通过高效破碎方式强化堆浸体系的浸出过程,可以解决堆浸周期长和浸出率低的问题,对低品位黄金矿山进一步降本增效具有很好的指导意义。

REFERENCES

[1] 王勇海, 宁新霞, 任金菊. 甘肃省某地金矿柱浸试验研究[J]. 矿产保护与利用, 2006(1): 33-36.

WANG Yong-hai, NING Xin-xia, REN Jin-ju. A study on column leaching of a gold ore from Gansu province[J]. Conservation and Utilization of Mineral Resources, 2006(1): 33-36.

[2] 黄志华, 杨政国, 苏秀珠. 低品位金矿石直接堆浸工艺研究[J]. 有色金属(冶炼部分), 2014(5): 52-55.

HUANG Zhi-hua, YANG Zheng-guo, SU Xiu-zhu. Technical study on heap leaching for low-grade crude gold ores[J]. Nonferrous Metals (Extractive Metallurgy). 2014(5): 52-55.

[3] 贺日应. 紫金山金矿堆浸试验研究[J]. 矿业快报, 2006, 25(12): 14-16.

HE Ri-ying. Research on heap leaching test of Zijinshan gold ores[J]. Express Information of Mining Industry, 2006, 25(12): 14-16.

[4] SHESTERNEV D M, MYAZIN V P. Gold heap leaching in the permafrost zone of Transbaikalia[J]. Journal of Mining Science, 2010, 46(5): 587-592.

[5] 侯 英, 丁亚卓, 印万忠, 姚 金, 罗溪梅, 王余莲, 孙大勇. 邦铺钼铜矿石高压辊磨后物料的特性[J]. 中南大学学报(自然科学版), 2013(12): 4781-4786.

HOU Ying, DING Ya-zhuo, YIN Wan-zhong, YAO Jin, LUO Xi-mei, WANG Yu-lian, SUN Da-yong. Product characteristics of Mo-Cu ore from Bangpu by high pressure grinding rolls[J]. Journal of Central South University (Science and Technology), 2013(12): 4781-4786.

[6] 李丽匣, 袁致涛, 郭小飞, 谢琪春. 高压辊磨超细碎对攀西钒钛磁铁矿分选的影响[J]. 东北大学学报(自然科学版), 2013, 34(9): 1335-1338.

LI Li-xia, YUAN Zhi-tao, GUO Xiao-fei, XIE Qi-chun. Influence of ultra-fine comminution by HPGR on separation of V-Ti magnetite in Panxi[J]. Journal of Northeastern University (Natural Science), 2013, 34(9): 1335-1338.

[7] 印万忠, 侯 英, 丁亚卓, 姚 金, 王余莲, 罗溪梅, 孙大勇. 破碎方式对邦铺钼铜矿石可磨性及钼浮选的影响[J]. 金属矿山, 2013(2): 86-89.

YIN Wan-zhong, HOU Ying, DING Ya-zhuo, YAO Jin, WANG Yu-lian, LUO Xi-mei, SUN Da-yong. Effect of different comminuting process on grindability and molybdenum flotation of Bangpu Mo-Cu ore[J]. Metal Mine, 2013(2): 86-89.

[8] MAXTON D, MORLEY C, BEARMAN R. A quantification of the benefits of high pressure rolls crushing in an operating environment [J]. Minerals Engineering, 2003, 16(9): 827-838.

[9] BATTERHAM R. Trends in comminution driven by energy[J]. Advanced Powder Technology, 2011, 22(1): 138-140.

[10] WANG Yan-ming, FORSSBERG E. Enhancement of energy efficiency for mechanical production of fine and ultra-fine particles in comminution[J]. China Particuology, 2007, 5(3): 193-201.

[11] ALTUN O, BENZER H, DUNDAR H. Comparison of open and closed circuit HPGR application on dry grinding circuit performance[J]. Minerals Engineering, 2011, 24(3): 267-275.

[12] KODALI P, DHAWAN N, DEPCI T, LIN C L, MILLER J D. Particle damage and exposure analysis in HPGR crushing of selected copper ores for column leaching[J]. Minerals Engineering, 2011, 24(13): 1478-1487.

[13] PATZELT N, KNECHT H, BAUM W. Case made for high-pressure roll-grinding in gold plants[J]. Mining Engineering, 1995, 47(6): 524-529.

[14] KELLY E G, SPOTTISWOOD K. The breakage function: What is it really? [J]. Minerals Engineering, 1990, 3(5): 405-414.

[15] 谢洪珍, 胡杰华, 阴 菡. 高压辊磨对矿石中金浸出影响试验研究[J]. 黄金科学技术, 2013(5): 145-148.

XIE Hong-zhen, HU Jie-hua, YIN Han. Experimental study on the effect of leaching of gold ore by high pressure roller mill[J]. Gold Science and Technology, 2013(5): 145-148.

[16] 段希祥. 碎矿与磨矿[M]. 2版. 北京: 冶金工业出版社, 2006: 10-25.

DUAN Xi-xiang. Crushing and grinding[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2006: 10-25.

[17] 尹升华, 陈 勋. 堆浸体系含水率的影响因素[J]. 中国有色金属学报, 2015, 25(7): 1961-1968.

YIN Sheng-hua, CHEN Xun. Influence factors of moisture content in heap leaching[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1961-1968.

[18] 陈友晴. Westerly花岗岩试样单轴压缩破坏瞬时微裂纹观察[J]. 岩石力学与工程学报, 2008, 27(12): 2440-2448.

CHEN You-qing. Observation of micro-cracks patterns in Westerly granite specimens stressed immediately before failure by uniaxial compressive loading[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(12): 2440-2448.

Influence mechanism of high pressure grinding rolls on heap leaching of gold ore

TANG Yuan, YIN Wan-zhong, MA Ying-qiang, CHI Xiao-peng, HUANG Fa-lan

(College of Zijin Mining, Fuzhou University, Fuzhou 350116, China)

Abstract: Through the column leaching experiments of low grade gold ore crushed by conventional jaw crusher and high pressure grinding rolls (HPGR), the influences of coarse particles processed by two different comminuting methods on the leaching rate were studied. Combined with the characteristics of products and microscopic analyses technology, the mechanism of HPGR method in the treatment process of gold ore was discussed furthermore. The results show that the products of HPGR are finer and containing richer micro cracks on particle surface and have higher saturated water content than that of conventional jaw crusher. HPGR can play a significant role in strengthening the penetration effect of heap leaching which can help to improve the leaching rate of gold ore at the same time. Under the same conditions, gold leaching rate of HPGR method can be improved by 3.5%-6.8%, meanwhile, the consumption of leaching solution is decreased by 3.2%-11.3%.

Key words: comminuting methods; high pressure grinding rolls; heap leaching; micro crack; saturated water content

Foundation item: Project(51374079) supported by the National Natural Science Foundation of China; Project (2015J05101) supported by the Natural Science Foundation of Fujian Province, China

Received date: 2015-09-28; Accepted date: 2016-01-18

Corresponding author: YIN Wan-zhong; Tel: +86-591-22866519; E-mail: yinwanzhong@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374079);福建省自然科学基金资助项目(2015J05101)

收稿日期:2015-09-28;修订日期:2016-01-18

通信作者:印万忠,教授,博士;电话:0591-22866519;E-mail:yinwanzhong@163.com