流变压铸工艺参数对过共晶Al-30%Si合金显微组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2017年第6期

论文作者:郑志凯 吉永健 毛卫民 岳锐 刘志勇

文章页码:1264 - 1272

关键词:过共晶铝硅合金;初生Si;振动蛇形通道;浇注工艺;流变压铸;显微组织;力学性能

Key words:hypereutectic Al-Si alloy; primary Si; vibration serpentine channel; pouring process; rheo-diecasting; microstructure; mechanical properties

摘 要:研究流变压铸工艺参数浇注温度、振动频率和蛇形通道弯道数量对Al-30%Si合金的显微组织和力学性能的影响。流变压铸过程中的半固态Al-30%Si合金浆料采用振动蛇形通道浇注工艺制备。实验结果表明:浇注温度、振动频率和通道数量对Al-30%Si合金显微组织和力学性能的影响较大。在浇注温度为850 °C、通道弯道数量为12和振动频率为80 Hz的条件下,流变压铸工艺制备的样品组织的初生硅晶粒被细化成平均粒径约为 24.6 μm的块状颗粒;此外,流变压铸样品的抗拉强度、伸长率和硬度分别为296 MPa、0.87%和HB 155。因此,振动蛇形通道浇注工艺能有效地细化组织中的初生Si晶粒。初生Si晶粒的细化是流变压铸样品力学性能改善的主要原因。

Abstract: The effects of pouring temperature, vibration frequency, and the number of curves in a serpentine channel, on the microstructure and mechanical properties of Al-30%Si alloy processed by rheo-diecasting (RDC) were investigated. The semisolid Al-30%Si alloy slurry was prepared by vibration serpentine channel pouring (VSCP) process in the RDC process. The results show that the pouring temperature, the vibration frequency, and the number of the curves strongly affect the microstructure and mechanical properties of Al-30%Si alloy. Under experimental conditions of a pouring temperature of 850 °C, a twelve-curve copper channel and a vibration frequency of 80 Hz, the primary Si grains are refined into fine compact grains with average grain size of about 24.6 μm in the RDC samples assisted with VSCP. Moreover, the ultimate tensile strength (UTS), elongation and hardness of the RDC sample are 296 MPa, 0.87% and HB 155, respectively. It is concluded that the VSCP process can effectively refine the primary Si grains. The refinement of primary Si grains is the major cause for the improvement of the mechanical properties of the RDC sample.

Trans. Nonferrous Met. Soc. China 27(2017) 1264-1272

Zhi-kai ZHENG1, Yong-jian JI1, Wei-min MAO1, Rui YUE1, Zhi-yong LIU2

1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China

Received 19 May 2016; accepted 9 October 2016

Abstract: The effects of pouring temperature, vibration frequency, and the number of curves in a serpentine channel, on the microstructure and mechanical properties of Al-30%Si alloy processed by rheo-diecasting (RDC) were investigated. The semisolid Al-30%Si alloy slurry was prepared by vibration serpentine channel pouring (VSCP) process in the RDC process. The results show that the pouring temperature, the vibration frequency, and the number of the curves strongly affect the microstructure and mechanical properties of Al-30%Si alloy. Under experimental conditions of a pouring temperature of 850 °C, a twelve-curve copper channel and a vibration frequency of 80 Hz, the primary Si grains are refined into fine compact grains with average grain size of about 24.6 μm in the RDC samples assisted with VSCP. Moreover, the ultimate tensile strength (UTS), elongation and hardness of the RDC sample are 296 MPa, 0.87% and HB 155, respectively. It is concluded that the VSCP process can effectively refine the primary Si grains. The refinement of primary Si grains is the major cause for the improvement of the mechanical properties of the RDC sample.

Key words: hypereutectic Al-Si alloy; primary Si; vibration serpentine channel; pouring process; rheo-diecasting; microstructure; mechanical properties

1 Introduction

High silicon (w(Si)>22%) aluminium alloys are widely used for making heat-resistant parts such as pistons of high speed engines, engine blocks, aircraft components and military applications due to the superior performances of high specific strength, excellent wear resistance and corrosion resistance, as well as low coefficient of thermal expansion [1-4]. In general, the mechanical properties of hypereutectic Al-Si alloys largely depend on the morphology and size of the primary Si grains. However, the morphology of primary Si grains is mainly star-like, or plate-like, or penniform and the Si grain size is very large after traditional solidification. So, it is difficult to improve the morphology of primary Si grains and refine the Si grain size through the conventional casting process. If the size and morphology of primary Si grains can be refined, the properties of hypereutectic Al-Si alloys with high Si content will be greatly improved [5,6].

The present investigations mainly focus on the microstructure and phase morphology of hypereutectic Al-Si alloys. However, the mechanical properties of high silicon (w(Si)>22%) Al-Si alloys are rarely reported. Diecasting is an efficient and economical process offering a broader range of shapes and components than any other manufacturing technique. However, the traditional diecasting process will produce a great amount of entrapped gas during the two first filling stages of die casting process. The presence of gas porosity in castings is harmful because the mechanical properties and pressure tightness are adversely affected [7,8]. Rheo-diecasting (RDC) can produce high quality components with high integrity and improved the performance [9,10]. The RDC process has a lot of advantages such as extremely low porosity, fine and uniform microstructure and improved mechanical properties. More importantly, the resulting RDC products have close-to-zero porosity and therefore can be heat- treated [11]. In the rheo-forming process, molten alloy is stirred as the temperature is decreased in order to create semi-solid slurry with a controlled grain size, which is then injected into a die and formed with a press, as reported by JIN et al [12]. There have been many new developed techniques to prepare semisolid alloy slurry. Among these new techniques, serpentine channel pouring (SCP) process is an environmentally safe technology with simple process and low cost [13-15]. In this study, we propose a novel method to prepare semi-solid Al-30%Si alloy slurry through a vibrated serpentine channel pouring (VSCP) process and investigate the mechanical properties of the Al-30%Si alloy processed by rheo-diecasting (RDC).

In recent years, the rheological forming process of semi-solid slurry has attracted more and more attention for its merits, such as simple process and low cost. The A356 alloy formed directly by rheo-squeeze casting of semi-solid slurry made with rotating magnetic field method showed excellent mechanical properties, as reported by ZHANG et al [16]. Recently, LIN et al [17] have used ultrasonic vibration (USV) to make semi-solid slurry, and it has significant effects on refining the primary Si grains of hypereutectic Al-Si alloy and modifying the intermetallic compounds such as Fe-containing phase. CAO et al [18] reported that heat treatment and P modifier could be used to prepare hypereutectic Al-50%Si alloy, and it could make the size of primary Si grains reduce to 48 μm. ZHENG et al [19] prepared semi-solid A390 alloy slurry through serpentine channel pouring (SCP) process near the liquidus temperature, and the fine primary Si grains with average grain size of about 20 μm were obtained in the A390 alloy.

The object of this paper is to investigate the effects of different process parameters on the microstructure and mechanical properties of Al-30%Si alloy. Different process parameters (i.e., the pouring temperature, the number of curves in the serpentine channel, and the vibration frequency of the channel) were varied to obtain a favorable as-cast microstructure and better mechanical properties. In addition, the refinement mechanism of the primary Si grains in the Al-30%Si alloy samples processed by RDC assisted with the vibration serpentine channel pouring (VSCP) process was also studied.

2 Experimental

2.1 Materials and equipments

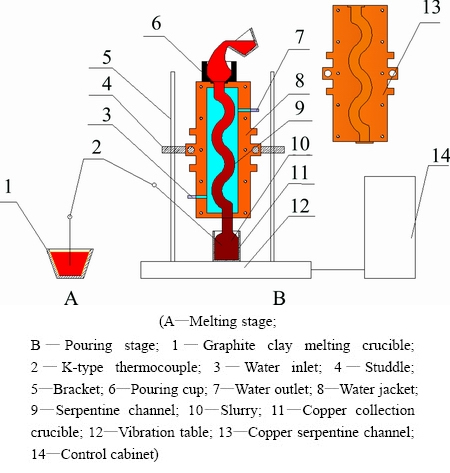

The schematic diagram of VSCP system is shown in Fig. 1. It consists of melting stage (A) and pouring stage (B). All experimental materials were melted in a 5 kW resistance furnace. The melt and isothermal holding temperatures were controlled by a PID temperature controller. The Al-30%Si alloy was melted in a clay-bonded graphite crucible. The vibration frequency and amplitude of the vibration table could be adjusted by the control cabinet. The collection crucible, with a diameter of 80 mm and a height of 150 mm, was made of red copper. The pouring temperatures and the temperature of the melt in the copper collection crucible were measured with a K-model handset thermocouple. The applied mechanical vibration power in this study was 3 kW, and the amplitude was 150 μm [20].

Fig. 1 Schematic diagram of VSCP system

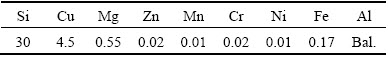

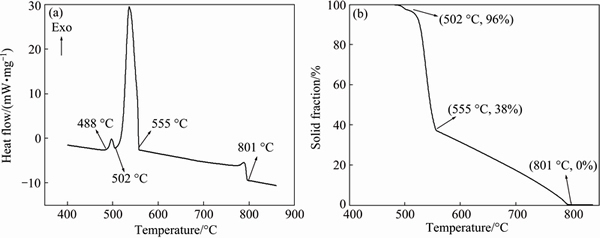

The newly produced cast alloy investigated had the composition shown in Table 1 and was prepared with commercial A390 aluminum alloy and Al-43%Si (mass fraction, the same in the following) master alloy, commercial pure Al (99.8%), pure Cu (99.99%) and pure Mg (99.9%). Differential scanning calorimetry (DSC) (NETZSCHSTA 409C/CD) was employed to determine the liquidus and solidus temperatures of the Al-30%Si alloy. The liquidus and the solidus temperatures of the alloy are 801 °C and 488 °C, respectively. The DSC curve of the alloy is shown in Fig. 2.

Table 1 Chemical composition of Al-30%Si alloy (mass fraction, %)

2.2 Methods

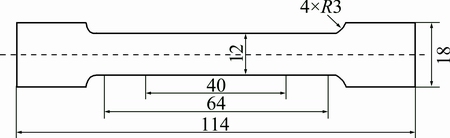

The experimental parameters are listed in Table 2. Firstly, the materials were melted in a graphite crucible at 920-950 °C. And the melt was degassed for 15 min with argon gas introduced through a graphite lance. The melt was allowed to cool down to a chosen pouring temperature near liquidus after degassing. The collection crucible was preheated to 430-450 °C by the heating furnace. Subsequently, the alloy melt was poured through a vibration serpentine channel that was continuously cooled with cooling water flow of 500 L/h and was allowed to flow into a collection crucible, and the semisolid slurry with a certain solid fraction was obtained. Finally, the semisolid slurry was transferred into a YYC180 machine with a 180 t clamping force, which was used to form standard tensile samples. The injection speed and injection pressure were 5 m/s and 70 MPa, respectively. The die used for casting test samples had six cavities, of which three had been subjected to solution treatment at 510 °C for 6 h and then artificial aging at 190 °C for 12 h (T6 heat-treated). The temperature of the die was kept at 210 °C during processing. The shape and dimensions of the tensile samples are shown in Fig. 3, and the standard tensile samples are based on GB/T228.1-2010.

Fig. 2 DSC curves of Al-30%Si alloy obtained during solidification (a) and solid fraction-temperature curve of Al-30%Si alloy (b)

Table 2 Process parameters and characteristic sizes of semi-solid slurry

Fig. 3 Schematic of tensile samples (unit: mm)

The specimens for the metallographic examination were cut from the ends of tensile test samples. After the samples were subjected to rough grinding, fine grinding, and polishing, the transverse of each sample was immersed into 0.5% HF (volume fraction) aqueous solution for 20 s for etching. The microstructures were examined using a Neuphoto21 optical microscope. Meanwhile, each of the primary Si grains was marked using professional image-analysis software (Image-Pro Plus), the area A and the perimeter P were also measured. Finally, the equivalent grain diameter D and the shape coefficient F of the primary Si grains were respectively calculated using Eqs. (1) and (2) [21]:

(1)

(1)

(2)

(2)

where D, Fs, A, N, and P are the equivalent grain diameter, the average shape coefficient, the area, the number and the perimeter of the primary Si grains, respectively. When the value of Fs approaches 1, the primary Si grains are more globular. The tensile tests were carried out using a CMT4105 testing machine at a corresponding speed of 1 mm/min. The average UTS was obtained from three tensile specimens for each specified experimental condition. The average Brinell hardness of five points on the sample surface was tested by HB-3000B Brinell hardness tester.

3 Results and discussion

3.1 Effects of pouring temperature on RDC samples

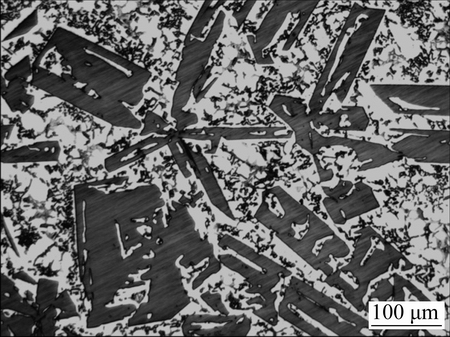

For the sake of contrast, the Al-30%Si alloy liquid was poured directly into the shot chamber of the die casting machine at 850 °C. Figure 4 shows the microstructure of the as-cast samples. The lightgray regions, the darkgray grains and the black regions in Fig. 4 refer to α(Al), primary Si grains and Al-Si eutectic phase, respectively. The primary Si grains are very coarse and their average grain size is 87.6 μm. The distribution of the primary Si grains is also non-uniform and the primary Si grains exhibit thicker plate-like and five-petal star-shape morphology. So, the UTS of the DC sample is only 133 MPa.

Fig. 4 Microstructure of as-cast DC Al-30%Si alloy poured at 850 °C

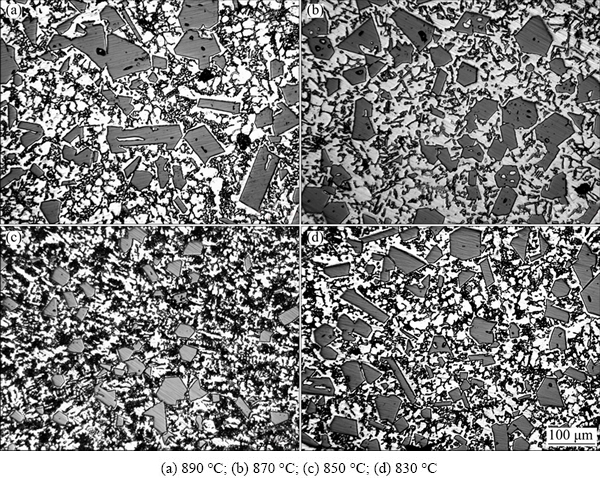

Fig. 5 Microstructures of as-cast samples processed by RDC assisted with VSCP at different pouring temperatures with vibration frequency of 80 Hz and eight-curve serpentine channel

When Al-30%Si alloy melt flows through the vibration serpentine channel, the melt temperatures out of the outlet will be below the liquidus temperature, which means that the Al-30%Si alloy melt has become the semi-solid slurry. To study the effects of the pouring temperature on the microstructures and mechanical properties of the RDC samples, an eight-curve copper serpentine channel and four different pouring temperatures were used under a vibration frequency of 80 Hz, as listed in Table 2. Figure 5(a) shows that almost all of the primary Si grains are coarse plate-like grains when the pouring temperature is 890 °C. However, the size of the primary Si grains in Fig. 5(a) is decreased significantly compared with that of the conventional DC microstructure in Fig. 4, and the average grain size of the primary Si grains is 35.5 μm. Figure 5(b) shows that the blocky or polygonal primary Si grains begin to appear when the pouring temperature is 870 °C, and the average grain size of the primary Si grains is reduced to 31.9 μm. Figure 5(c) shows that when the pouring temperature is decreased to 850 °C, almost all of the primary Si grains are refined into blocky or polygonal ones with an average grain size of 27.2 μm. Figure 5(d) shows that when the pouring temperature is 830 °C, the average grain size of the primary Si grains is 30.3 μm and the number of the fine plate-like primary Si grains increases gradually. In summary, with decreasing pouring temperature of VSCP, the average grain size of the primary Si grains reaches a minimum value when the pouring temperature is 850 °C, and then increases again slightly.

The result may be attributed to the survival of the primary Si nuclei induced by VSCP in the alloy melt. LIN et al [17] and LIU et al [22] suggested that the degree of supercooling of the alloy melt strongly influences the final microstructure. According to the principle of nucleation kinetics, the relationship between the degree of supercooling, ΔT, and the critical nucleation radius, Rk, can be calculated by [23]

Rk=(2σSLTm)/(ΔHmΔT) (3)

where σSL, Tm and ΔHm can be considered as constants for a certain alloy. Therefore, the greater the degree of supercooling is, the smaller the critical nucleation radius is and the lower the nucleation energy is. The low nucleation energy can promote the increase of the number of crystal nuclei, which results in the grain refinement. In general, when the pouring temperature is high, more physical heat contains in the Al-30%Si alloy liquid. When higher temperature Al-30%Si alloy liquid flows through the serpentine channel, more heat will inevitably transfer to the channel wall. As a result, the chilling effect of the channel wall is diminished, which results in a higher outlet temperature. Because the chilling effect is constantly being diminished, the speed at which the whole Al-30%Si alloy liquid temperature decreases is also diminished, which can reduce the possibility of primary Si precipitation in the supercooled region of the alloy melt and consequently decrease the number of primary Si crystal nuclei. Meanwhile, the primary Si crystal nuclei may be remelted under the conditions of the subsequent overheated alloy liquid through the serpentine channel. The lower pouring temperatures can cause a greater degree of supercooling, which is beneficial to the nucleation of the primary Si grains and results in the generation of a mass of primary Si crystal nuclei in the alloy melt. However, KANG et al [24] discovered that when the pouring temperature is too low, the primary Si grains can precipitate out before or during the pouring process, which provides more time to grow up for these part of primary Si grains, finally leading to an increase in the size of the primary Si grains. In summary, the greater the nucleation rate is, the more the number of crystal nucleus of unit volume is, the smaller the room for each grain growing up is, so the grain size is small. Meanwhile, the rapid cooling of the copper serpentine channel and the mold of die casting machine can restrain the growth of the primary Si grains. The combined action of the promotion of nucleation and the restriction of growth results in the refinement of the primary Si grains. Besides, the shape factor of all of the primary Si grains is about 0.8, which indicates that the effect of pouring temperature on the shape factor of the primary Si grains is relatively small.

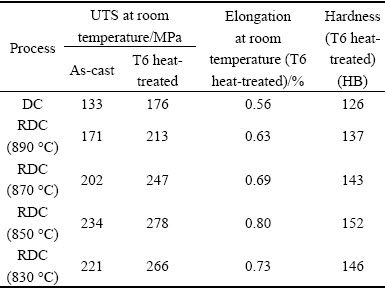

The obtained mechanical properties of the Al-30%Si alloy processed by DC and RDC assisted with VSCP at different pouring temperatures are tabulated in Table 3. In T6 heat treatment state, the mechanical properties of the Al-30%Si alloy processed by RDC at the pouring temperature of 850 °C are the best. The UTS, elongation and hardness of the RDC sample are 278 MPa, 0.80% and HB 152, respectively. Compared with the conventional DC process, RDC samples have much improved UTS and tensile elongation. The UTS, elongation and hardness of the RDC samples are approximately 57.9%, 42.9% and 20.6% higher than those of the DC samples, respectively. It might be because the coarse plate-like primary Si grains which can crack the Al matrix give rise to the crack initiation and shrinkage porosity in the DC sample [25]. While the primary Si grains in the RDC sample are refined into fine compact particles, which can reduce or even eliminate the crack initiation and shrinkage porosity. Thus, good combination of strength and elongation of RDC samples is mainly dependent on the extremely low porosity, fine size and granular morphology of the primary Si grains.

Table 3 Mechanical properties of Al-30%Si alloy processed by RDC assisted with VSCP at different pouring temperatures

3.2 Effects of vibration frequency on RDC samples

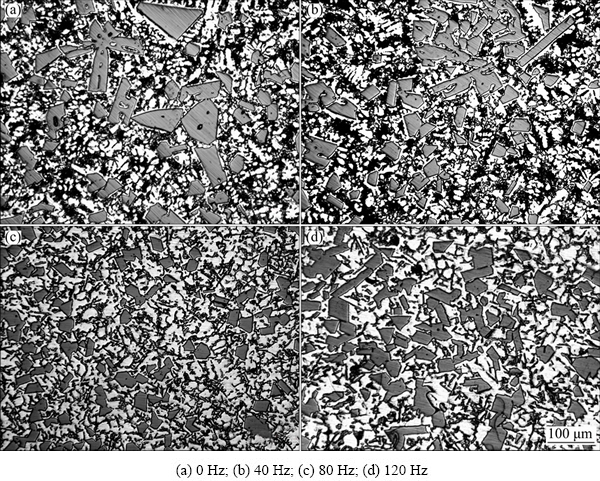

As is well known, the mechanical properties are largely determined by the microstructure. In order to decrease the size and promote a granular morphology of primary Si grains, the vibration frequency of the VSCP is particularly important. Figure 6 shows the microstructures of the RDC samples, where an twelve- curve copper serpentine channel and four different vibration frequencies were used under a pouring temperature of 850 °C. Compared with the conventional DC microstructure in Fig. 4, the average grain size of the primary Si grains in Fig. 6 is obviously decreased. Figure 6(a) shows that, when the VSCP is applied without vibration, almost all of the primary Si grains are coarse plate-like grains and the average grain size of primary Si grains is 32.3 μm. Figure 6(b) shows that, when the VSCP is applied with the vibration frequency of 40 Hz, the coarse plate-like primary Si grains are refined into fine plate-like grains, and the average grain size of primary Si grains reduces to 28.1 μm. Figure 6(c) shows that when the vibration frequency is increased to 80 Hz, almost all of the primary Si grains are refined into fine compact particles with the average grain size of 24.6 μm. The average grain size increases to 27.1 μm when the vibration frequency is increased to 120 Hz, even some primary Si grains exhibit a fine plate-like morphology, as shown in Fig. 6(d).

Compared with the microstructure without the vibration in Fig. 6(a), the primary Si grains in the microstructures with the vibration are refined significantly. This could be mainly attributed to the chilling effect induced by VSCP. Due to the intense chilling effect of the copper serpentine channel, the Al-30%Si alloy liquid which is close to the channel inner wall, can be prone to cool below the liquidus temperature. So, the primary Si crystal nuclei can precipitate easily and grow up along the inner wall of the channel. Meanwhile, the vibration of the serpentine channel can accelerate the exfoliation of primary Si grains and provide the kinetic energy for them to move to the solid-liquid interface. Due to the scouring effect of the subsequent alloy melt, the exfoliated primary Si grains at the solid-liquid interface can be taken away, which results in the continual proliferation of primary Si crystal nuclei within the Al-30%Si alloy melt. Based on the above two points, a large amount primary Si crystal nuclei and free primary Si grains can be brought into the collection crucible, the primary Si grains are refined eventually.

Fig. 6 Microstructures of as-cast samples processed by RDC assisted with VSCP at 850 °C, with twelve-curve serpentine channel and different vibration frequencies

As shown in Fig. 6, at a certain pouring temperature and number of curves in the serpentine channel, with increasing the vibration frequency of VSCP, the average grain size of the primary Si grains reaches a minimum value when the vibration frequency is 80 Hz, and then increases slightly. The relationship between the vibration energy, E, and the vibration frequency, f, was studied by CAMPBELL [26], which can be defined by

E=8π2ma2f 3 (4)

where m is the mass and a is the amplitude of the vibration table, which can be considered as constants for this study. It is clear that the vibration energy increases with increasing the vibration frequency. When the vibration frequency is 40 Hz, the vibration energy may be insufficient, which results in a small amount of primary Si grains to be exfoliated and cannot make all of them move to the solid-liquid interface. So, the average grain size of the primary Si grains is relatively large. When the vibration frequency increases to 80 Hz, the enhanced vibration energy increases the number of the exfoliated primary Si grains. The sufficient kinetic energy maybe makes all the exfoliated primary Si grains move to the solid-liquid interface, so, the subsequent Al-30%Si alloy melt can bring them into the collection crucible. When the vibration frequency continues to increase to 120 Hz, the vibration energy is further enhanced. However, due to the excessive kinetic energy, some part of the exfoliated primary Si grains maybe move to the superheated liquid region. Consequently, this part of the exfoliated primary Si grains may be remelted, which decreases the effective nucleation rate of the primary Si crystal nuclei within the Al-30%Si alloy melt. As a result, with increasing the vibration frequency of VSCP, the average grain size of the primary Si grains decreases at first and then increases slightly.

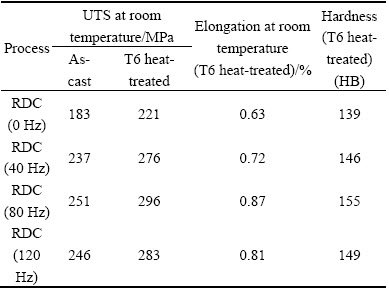

Table 4 shows a comparison of mechanical properties of the Al-30%Si alloy samples processed by RDC assisted with VSCP at different vibration frequencies. As can be seen, when the VSCP is applied at a vibration frequency of 80 Hz, the mechanical properties of the RDC samples are the best. The UTS, elongation and hardness of the RDC sample are 296 MPa, 0.87% and HB 155, respectively. This is mainly because the fine compact primary Si grains can enhance the mechanical properties of the RDC samples.

Table 4 Mechanical properties of Al-30%Si alloy processed by RDC assisted with VSCP at different vibration frequencies

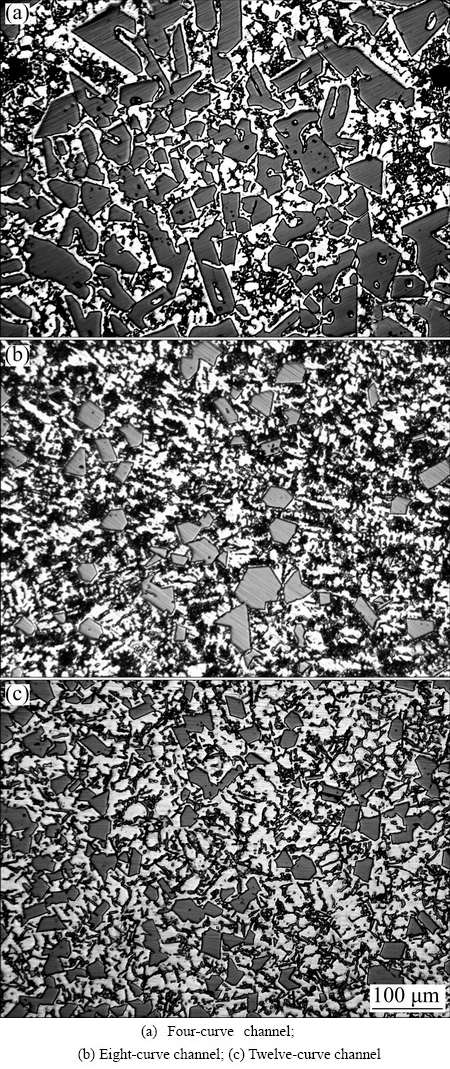

3.3 Effects of number of curves on RDC samples

Figure 7 shows the microstructures of the RDC samples, of which three different numbers of curves in the serpentine channel were used under a pouring temperature of 850 °C and a vibration frequency of 80 Hz. Figure 7(a) shows that almost all of the primary Si grains are coarse plate-like grains with the average grain size of 32.1 μm. The coarse plate-like primary Si grains are refined to fine plate-like grains and the average grain size of the primary Si grains reduces to 27.2 μm, as shown in Fig. 7(b). Figure 7(c) shows that when the number of curves increases to 12, almost all of the primary Si grains are refined into fine compact particles with the average grain size of 24.6 μm.

Fig. 7 Microstructures of as-cast samples processed by RDC assisted with VSCP at 850 °C, vibration frequency of 80 Hz and different numbers of curves

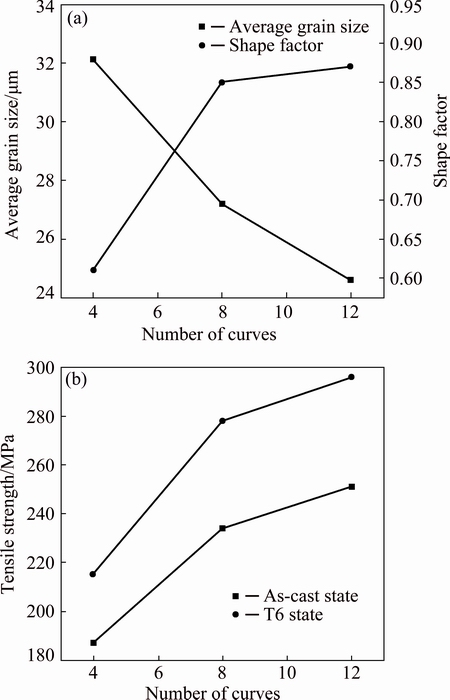

As shown in Fig. 8, under the same other conditions, the average grain size of the primary Si grains decreases with increasing the number of curves in the serpentine channel. As the number of curves in the serpentine channel increases, the area of the serpentine channel inner wall which is directly in contact with the alloy melt is enlarged. This is beneficial to heterogeneous nucleation and chilling nucleation of the alloy melt. With increasing the area of heterogeneous nucleation and chilling nucleation substrate, more crystal nuclei are generated. Meanwhile, as the area of the serpentine channel inner wall increases, the superheat and latent heat of the alloy melt are more easily absorbed by the copper serpentine channel, thereby the crystal nuclei are also easily preserved. Moreover, with increasing the number of curves in the serpentine channel, the collision frequency among the primary Si grains and between primary Si grains and the serpentine channel inner walls can be constantly enhanced, which effectively promotes the refinement and regularization of the plate-like grains. Finally, the average grain size of the primary Si grains is substantially decreased.

Fig. 8 Average grain size and shape factor versus number of curves (a) and tensile strength versus number of curves (b)

Figure 8(a) shows the effect of the number of curves on the average grain size and the shape factor of the primary Si grains. Figure 8(b) shows the effect of the number of curves on the UTS of RDC samples. The mechanical properties of the Al-30%Si alloy processed by RDC with different numbers of curves change in accordance with the effect of different numbers of curves on the microstructure. When the number of curves is four, the coarse plate-like primary Si grains are undoubtedly harmful to the UTS. The fine primary Si grains formed under the condition of twelve curve numbers have a positive effect on the UTS. Therefore, the mechanical properties of the RDC sample assisted with VSCP and the twelve-curve copper serpentine channel are the best. Besides, T6 heat treatment can significantly improve the mechanical properties of the RDC sample, as shown in Fig. 8(b).

4 Conclusions

1) The primary Si grains in the Al-30%Si alloy samples processed by RDC assisted with VSCP can be successfully refined. The primary Si grains are refined to the greatest extent and the plate-like grains are changed into fine compact particles with the average grain size of 24.6 μm when the VSCP is applied at a pouring temperature of 850 °C, a twelve-curve copper serpentine channel and a vibration frequency of 80 Hz. It is considered that the chilling effect induced by VSCP results in the refinement of primary Si grains.

2) Under the same other conditions, with increasing the vibration frequency and decreasing the pouring temperature, the average grain size of the primary Si grains firstly decreases and then increases slightly. Furthermore, the average grain size of the primary Si grains decreases with increasing the number of curves in the serpentine channel.

3) The obtained mechanical properties of the RDC Al-30%Si alloy processed by RDC assisted with VSCP at different process parameters change in accordance with the effects of the process parameters on the microstructure. The mechanical properties of the RDC sample assisted with VSCP at a pouring temperature of 850 °C, a twelve-curve copper channel and a vibration frequency of 80 Hz are the best. The UTS, elongation and hardness of the RDC sample are 296 MPa, 0.87% and HB 155, respectively.

4) In T6 heat treatment state, compared with the DC sample, the UTS, elongation and hardness of the RDC sample are increased by 57.9%, 42.9% and 20.6%, respectively.

References

[1] ABU-DHEIR N, KHRAISHEH M, SAITO K, MALE A. Silicon morphology modification in the eutectic Al-Si alloy using mechanical mold vibration [J]. Materials Science and Engineering A, 2005, 393: 109-117.

[2] BELOV N A, ESKIN D G, AVXENTIEVA N N. Constituent phase diagrams of the Al-Cu-Fe-Mg-Ni-Si system and their application to the analysis of aluminium piston alloys [J]. Acta Materialia, 2005, 53: 4709-4722.

[3] LASA L, RODRIGUEZ-IBABE J M. Wear behaviour of eutectic and hypereutectic Al-Si-Cu-Mg casting alloys tested against a composite brake pad [J]. Materials Science and Engineering A, 2003, 363: 193-202.

[4] YAMAGATA H, KURITA H, ANIOLEK M, KASPRZAK W, SOKOLOWSKI J H. Thermal and metallographic characteristics of the Al-20%Si high-pressure die-casting alloy for monolithic cylinder blocks [J]. Journal of Materials Processing Technology, 2008, 199: 84-90.

[5] KOCATEPE K. Effect of low frequency vibration on porosity of LM25 and LM6 alloys [J]. Materials & Design, 2007, 28: 1767-1775.

[6] STEENT H A H, HELLAWELL A. Structure and properties of aluminium-silicon eutectic alloys [J]. Acta Metallurgica, 1972, 20: 363-370.

[7] LUMLEY R N, DONNELL R G O, GUNASEGARAM D R, GIVORD M. Heat treatment of high-pressure die castings [J]. Metallurgical and Materials Transactions A, 2007, 38: 2564-2574.

[8] CHEN Zhan-wei, JAHEDI M Z. Die erosion and its effect on soldering formation in high pressure die casting of aluminium alloys [J]. Materials & Design, 1999, 20: 303-309.

[9] LU Shu-lin, WU Shu-sen, LIN Chong, HU Zu-qi, AN Ping. Preparation and rheocasting of semisolid slurry of 5083 Al alloy with indirect ultrasonic vibration process [J]. Materials Science and Engineering A, 2011, 528: 8635-8640.

[10] WU Shu-sen, LU Shu-lin, AN Ping, NAKAE H. Microstructure and property of rheocasting aluminum-alloy made with indirect ultrasonic vibration process [J]. Materials Letters, 2012, 73: 150-153.

[11] WANG Y, LIU G, FAN Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment [J]. Acta Materialia, 2006, 54: 689-699.

[12] JIN C K, JANG C H, KANG C G. Die design method for thin plates by indirect rheo-casting process and effect of die cavity friction and punch speed on microstructures and mechanical properties [J]. Journal of Materials Processing Technology, 2015, 224: 156-168.

[13] LIU Zhi-yong, MAO Wei-min, WANG Wei-pan, ZHENG Zhi-kai. Preparation of semi-solid A380 aluminum alloy slurry by serpentine channel [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1419-1426.

[14] ZHU Wen-zhi, MAO Wei-min, TU Qin. Preparation of semi-solid 7075 aluminum alloy slurry by serpentine pouring channel [J]. Special Casting and Nonferrous Alloys, 2014, 24: 954-960. (in Chinese)

[15] YANG Xiao-rong, MAO Wen-min, SUN Bin-yu. Preparation of semisolid A356 alloy slurry with larger capacity cast by serpentine channel [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 455-460.

[16] ZHANG Xiao-li, LI Ting-ju, XIE Shui-sheng, TENG Hai-tao, JIN Jun-ze. Microstructure evolution of A356 alloy in a novel rheocasting approach [J]. Journal of Materials Processing Technology, 2009, 209: 2092-2098.

[17] LIN Chong, WU Shu-sen, LU Shu-lin, AN Ping, WAN Li. Microstructure and mechanical properties of rheo-diecast hypereutectic Al-Si alloy with 2% Fe assisted with ultrasonic vibration process [J]. Journal of Alloys and Compounds, 2013, 568: 42-48.

[18] CAO Fu-yang, JIA Yan-dong, PRASHANTH K G, MA Pan, LIU Jing-shun, SCUDINO S, HUANG Feng, ECKERT J, SUN Jian-fei. Evolution of microstructure and mechanical properties of as-cast Al-50Si alloy due to heat treatment and P modifier content [J]. Materials & Design, 2015, 74: 150-156.

[19] ZHENG Zhi-kai, MAO Wei-min, YAN Bin-quan. Refinement of primary Si grains of A390 alloy slurry through serpentine channel pouring process [J]. China Foundry, 2015, 12: 431-439. (in Chinese)

[20] CHIRUTA G, STEFANESCU I, SOARES D, SILVA F S. Influence of vibration on the solidification behaviour and tensile properties of an Al-18wt%Si alloy [J]. Materials & Design, 2009, 30: 1575-1580.

[21] TANG Wei-neng, CHEN Rong-shi, ZHOU Jie, HAN En-hou. Effects of ECAE temperature and billet orientation on the microstructure, texture evolution and mechanical properties of a Mg-Zn-Y-Zr alloy [J]. Materials Science and Engineering A, 2009, 499: 404-410.

[22] LIU Zheng, MAO Wei-min, ZHAO Zhen-duo. Research on semi-solid slurry of a hypoeutectic Al-Si alloy prepared by low superheat pouring and weak electromagnetic stirring [J]. Rare Metals, 2006, 25: 177-183.

[23] JUNG H K, KANG C G. Reheating process of cast and wrought aluminum alloys for thixoforging and their globularization mechanism [J]. Journal of Materials Processing Technology, 2000, 104: 244-253.

[24] KANG H S, YOON W Y, KIM K H, KIM M H, YOON E P. Microstructure selections in the undercooled hypereutectic Al-Si alloys [J]. Materials Science and Engineering A, 2005, 404: 117-123.

[25] RAGAB K A, SAMUEL A M, AL-AHMARI A M A, SAMUEL F H, DOTY H W. Influence of fluidized sand bed heat treatment on the performance of Al-Si cast alloys [J]. Materials & Design, 2011, 32: 1177-1193.

[26] CAMPBELL J. Effects of vibration during solidification [C]//Proceedings of the Second International Metals Reviews. London: Laylor & Francis Press, 1981: 71-108.

郑志凯1,吉永健1,毛卫民1,岳 锐1,刘志勇2

1. 北京科技大学 材料科学与工程学院,北京 100083;2. 清华大学 机械工程系,北京 100084

摘 要:研究流变压铸工艺参数浇注温度、振动频率和蛇形通道弯道数量对Al-30%Si合金的显微组织和力学性能的影响。流变压铸过程中的半固态Al-30%Si合金浆料采用振动蛇形通道浇注工艺制备。实验结果表明:浇注温度、振动频率和通道数量对Al-30%Si合金显微组织和力学性能的影响较大。在浇注温度为850 °C、通道弯道数量为12和振动频率为80 Hz的条件下,流变压铸工艺制备的样品组织的初生硅晶粒被细化成平均粒径约为24.6 μm的块状颗粒;此外,流变压铸样品的抗拉强度、伸长率和硬度分别为296 MPa、0.87%和HB 155。因此,振动蛇形通道浇注工艺能有效地细化组织中的初生Si晶粒。初生Si晶粒的细化是流变压铸样品力学性能改善的主要原因。

关键词:过共晶铝硅合金;初生Si;振动蛇形通道;浇注工艺;流变压铸;显微组织;力学性能

(Edited by Wei-ping CHEN)

Foundation item: Project (5077400) supported by the National Natural Science Foundation of China

Corresponding author: Wei-min MAO; Tel: +86-13911069562; E-mail: weiminmao@263.net

DOI: 10.1016/S1003-6326(17)60147-X