文章编号:1004-0609(2012)10-2777-06

浆料浇注温度对流变压铸件组织和力学性能的影响

赵君文1,戴光泽1,吴树森2,黄兴民1,韩 靖1

(1. 西南交通大学 材料科学与工程学院,成都 610031;

2. 华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要:将采用超声振动制备的过共晶Al-Si合金A390浆料在不同温度下进行流变压铸成形,研究浆料浇注温度对过共晶Al-Si合金流变压铸试样组织和力学性能的影响。结果表明:过共晶Al-Si合金A390流变压铸试样组织中初生Si主要由浆料制备过程中形成的大块Si(Si1)和在压铸模型腔中形成的细小Si(Si3)组成;在580~640 ℃范围内,随着浆料浇注温度升高,Si1平均尺寸先减小后增大,而Si3尺寸稳定在7~15 μm之间。过共晶Al-Si合金A390半固态浆料的适宜浇注温度范围为600~620 ℃,在此范围内可以得到抗拉强度超过260 MPa的A390合金流变压铸试样。

关键词:Al-Si合金;半固态浆料;流变压铸;过共晶;力学性能

中图分类号:TG249.9;TG146.2;O426.9 文献标志码:A

Effect of slurry pouring temperature on

microstructure and mechanical properties of rheo-diecasting

ZHAO Jun-wen1, DAI Guang-ze1, WU Shu-sen2, HUANG Xing-min1, HAN Jing1

(1. School of Materials Science and Engineering, Southwest Jiaotong University, Chengdu 610031, China;

2. State Key Laboratory of Materials Processing and Die & Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The hypereutectic Al-Si alloy A390 slurry was prepared by ultrasonic vibration and rheo-diecasted at different temperatures, and the effect of slurry pouring temperature on the microstructure and mechanical properties of hypereutectic Al-Si alloy rheo-diecasting sample was investigated. The results show that, the primary Si in the microstructure of rheo-diecasting sample of A390 alloy is mainly composed of large Si (Si1) formed during slurry preparation process and small Si (Si3) formed in die cavity; with the slurry pouring temperature increasing from 580 to 640 ℃, the average size of Si1 first decreases and then increases while that of Si3 maintains in the range of 7-15 μm. It is also found that the slurry pouring temperature suitable for rheo-diecasting of hypereutectic Al-Si alloy A390 semi-solid slurry is 600-620 ℃, and in this range the tensile strength of rheo-diecasting sample is up to more than 260 MPa.

Key words: Al-Si alloy; semisolid slurry; rheo-diecasting; hypereutectic; mechanical properties

基金项目:国家“十一五”科技支撑计划资助项目(2009BAG12A07);中央高校基本科研业务费资助项目(SWJTU09ZT22, SWJTU09BR149);2010年度聘请外籍教师教育部重点项目([2010]33)

收稿日期:2011-11-18;修订日期:2012-04-04

通信作者:赵君文,讲师,博士;电话:028-87600724;E-mail: swjtuzjw@swjtu.cn

过共晶Al-Si合金具有低热膨胀系数、高硬度和高耐磨性等优良性能,常用于制造活塞、缸体、泵体和空调压缩机等。然而,常用的过共晶Al-Si合金 (如A390合金)凝固温度区间大、初生固相少,使得该类合金铸造时组织中初生Si粗大、共晶Si呈针状,组织偏析严重,很难得到力学性能优良的铸件[1]。

半固态铸造是一种能够解决上述问题的技术方法之一,但过共晶Al-Si合金半固态铸造技术一直限于触变铸造[2-5]。众所周知,相对于触变铸造,流变铸造在成本和效率等方面具有优势,并已成功用于亚共晶Al-Si合金零件的制造[6-8]。然而,经济并可得到合格组织的过共晶Al-Si合金流变铸造工艺却鲜见报道[9]。

超声振动能够制备高质量的金属半固态坯料和浆料[10-12],超声制备浆料参数对浆料组织的影响已有很多研究,但缺乏超声制备浆料参数对浆料流变压铸组织与性能影响的研究。同时,半固态浆料的浇注温度对流变浆料的充型有至关重要的影响,温度太高,使得浆料充型类似于液态,难以发挥半固态成形的优点,而如果温度太低,因浆料固相率过高,造成充型阻力太大,使得最终成型件组织不致密,甚至出现浇不足和冷隔现象。因此,本文作者进行了A390合金半固态浆料浇注温度对流变压铸件组织和性能影响规律的研究。

1 实验

本试验所用材料A390合金采用Al-22Si中间合金、纯Al、纯Cu和纯Mg配置而成,其成分为(质量分数):17% Si,4.5% Cu,0.6% Mg,其余为Al。所采用的A390合金的固相线温度为505 ℃,液相线温度为650 ℃。使用的浆料制备试验装置见文献[13],将配制好的合金熔体进行除气精炼后冷却至660~ 730 ℃待浇;打开电炉将制浆样杯及超声振动头预热到530~580 ℃,同时预设好超声振动参数;从坩埚中取一定量熔体浇入样杯中并启动超声振动,通过熔体和样杯之间的热平衡,熔体会很快冷到所需的半固态浇注温度范围内,经过1 min超声振动后,将浆料倒入压室压铸,其结构如图1所示。值得说明的是,在此,半固态浆料浇注温度是指超声振动结束后转移浇入压室前所测的温度。

对于流变压铸成形试验,浆料进行压铸前,将压铸模具预热至150 ℃左右。试验中压铸参数固定,即压射压力为80 MPa,压射速度约为1.5 m/s,主要研究浆料浇注温度对流变压铸件组织与性能的影响,浆料浇注量为600 g左右。压铸出的A型力学性能试样(见图1(a)中右边两试样)先进行密度测定,再进行拉 伸性能测试,然后从位置A处取长度为10 mm的试样进行组织观察和金相分析。经嵌样、磨削、抛光并用0.5%(体积分数) 氢氟酸溶液腐蚀后进行金相观察,对每个试样用数码相机在不同位置拍照,然后使用金相分析软件对各条件下试样的金相组织进行定量分析。

图1 压铸试样及右边试样部分尺寸

Fig. 1 Schematic diagrams of rheo-diecasting(a) and dimension(mm) of right two parts(b) (A is position where specimen is taken for microstructure observation)

2 结果与分析

2.1 微观组织的影响

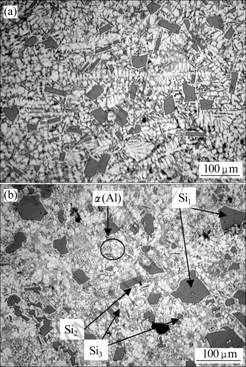

图2所示为过共晶Al-Si合金A390的微观组织。由图2可知,过共晶Al-Si合金A390流变压铸件组织明显不同于液态压铸件组织(参见文献[13]),亦与同温度下浆料组织有显著区别(见图2(a)),其组织由分布均匀的初生Si、细小等轴状α(Al)和Al-Si共晶组织构 成。从图中亦可见,初生Si有3种明显不同的形态,即大块状的Si1、少量形状不规则的Si2和大量细小的Si3组成。由于Si2数量少,对性能的影响不显著,在此,不再对其做详细研究。

显然,Si1是在超声浆料制备过程中形成的,大量细小的Si颗粒Si3 (Si3)是在浆料充型完毕后在压铸型腔中形成的,而个别条状的Si粒(Si2)有可能是在浆料转移和压室中没有超声作用下形核并快速生长而形 成的。

图2 过共晶Al-Si合金A390的微观组织

Fig. 2 Microstructures of typical A390 alloy slurry(a) and rheo-diecasting sample(b)with slurry pouring temperature of 615 ℃(In Fig.2(b), large Si particles (Si1) formed inside slurry maker, Si plates (Si2) formed inside shot sleeve or during slurry transferring, and fine Si particles (Si3) formed inside die cavity, as well as equiaxed primary α(Al))

图3所示为3个不同浆料浇注温度下流变压铸件的微观组织。由图3可以看出不同浆料浇注温度下的初生Si形貌,即3种形态初生Si的相对数量、大小和形状区别明显。浆料浇注温度较高时,Si1较大,而且形状不规整,当浆料浇注温度降至610 ℃时,Si1有所减小,而温度再下降至580℃时,Si1又增大但形状较规整。对不同浆料浇注温度下流变压铸试样微观组织进行统计分析,图4所示为初生Si平均颗粒直径随浆料浇注温度的变化。由图4可知,Si1平均尺寸随浆料浇注温度呈抛物线变化,随着浆料浇注温度从580 ℃升高到640 ℃,初生Si1平均尺寸从580 ℃时的49 μm降低至610 ℃的34 μm,而随着浆料浇注温度的进一步上升,Si1平均尺寸又增大,640 ℃时达56 μm;对于Si3,随着浆料浇注温度升高,其平均尺寸总体呈增大趋势,但稳定在7~15 μm,变化不大。Si3平均尺寸随浆料浇注温度下降变化不大,在7~15 μm之间。流变压铸试样(浇注温度为620 ℃)组织中各尺寸范围初生Si粒的分布规律如图5所示,其呈现出明显的两个分布峰,并且小粒子数量远大于大粒子的数量。值得一提的是,在其他浆料浇注温度下获得的流变压铸试样组织也具有这种特征。对不同浆料浇注温度下各尺寸Si粒定量分析得出,在所研究的浆料浇注温度范围内,初生Si1量为5%~7%(体积分数),Si3量为3%~5%,而Si2量低于1%,均随温度变化不大。

图3 不同浆料浇注温度下的流变压铸件微观组织

Fig. 3 Microstructures of A390 rheo-diecasting samples at different slurry pouring temperatures: (a) 640 ℃; (b) 610 ℃; (c) 580 ℃

图4 初生Si平均颗粒直径随浆料浇注温度的变化

Fig. 4 Average Si particle size as function of slurry pouring temperature

在过共晶Al-Si合金A390浆料制备过程中,浆料过冷度偏小,导致初生Si的形核少,且生长时间较长,故初生Si1尺寸大且数量少,而浆料制备过程中超声声场的作用抑制了Si1长成板片状和五瓣星状,促使其以颗粒状的方式生长。但浆料浇注温度越高,浆料制备后浇注过程中Si1在无超声场作用下自由生长时间就越长,因此,浆料浇注温度越高,流变压铸试样中Si1尺寸越大,形状越不规则。而浆料充填型腔后,由于模具的高冷却速度以及压射冲头施加的高压力作用下,剩余液相在非常大的过冷度下大量形核,使浆料的形核率很高,而高冷却速度使核心生长时间很短,因此Si3数量多,尺寸小。总体而言,浆料浇注温度越低,Si3核心生长时间越短,Si3尺寸就越小。

图5 浇注温度为620 ℃时初生Si颗粒直径分布

Fig. 5 Size distribution of primary Si particles for A390 rheo- diecasting samples with slurry pouring temperature of 620 ℃

对于初生α(Al),其尺寸细小,呈现等轴状或非枝晶形貌。如此细小的等轴状α(Al)显然是在压铸模型 腔中形成,即在浆料制备过程中没有形成初生α(Al),这与文献[4, 14]中A390合金半固态组织有区别,分析认为,主要是由于在本研究中为了保证浆料的流动性,所采用的制浆温度较高,不满足浆料制备过程中形成初生α(Al)的条件。

同时观察发现,浇注温度不同,其组织中气孔或缩孔的数量也有差别。温度较高时,组织里有较多的孔洞,超声对浆料的除气功能难以得到体现,从而影响流变压铸件性能的提高;随着浆料浇注温度降低,组织中孔洞缺陷的数量显著减少,但当浇注温度低于610 ℃时,组织中又会出现明显孔洞,温度越低孔洞缺陷增多。

2.2 力学性能的影响

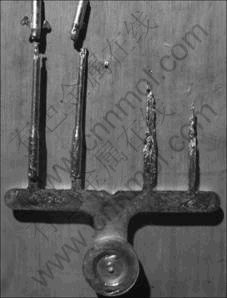

浆料浇注温度在580 ℃以上时,A型力学性能 试样能够完整充型,而当浇注温度低于580 ℃,如 575 ℃时,A型试样出现冷隔或浇不足现象(见图6),其他两类试样则完全不能成形。

图7所示为试样抗拉强度随浆料浇注温度的变化关系图。从图7可以看出,随着浆料浇注温度从 580 ℃上升到600 ℃,流变压铸件抗拉强度快速上 升,从199 MPa增大到259 MPa;但浆料浇注温度继续上升,流变压铸件抗拉强度逐渐降低,从262 MPa降至236 MPa。

虽然A390合金固相线温度为505 ℃,但由于A390合金固相率随温度变化曲线突变点在565 ℃ (A390合金固相率随温度的变化曲线见文献[15]),故若浆料浇注温度太低,由于冷却浆料在压入型腔之前固相率已达到很高,从而导致充型不足(见图6),同时最后凝固的区域得不到足够金属液的补充,使组织中形成大量缩孔。因此,考虑到在浆料转移中和浇入压室后开始压铸之前浆料浇注温度继续降低,固相率继续增加,浆料浇注温度不应低于580 ℃。随着浆料浇注温度的升高,浆料在固相率急剧增大前可充满型腔,压力也可以传递到整个试样,使试样致密,从而强度升高,但更高的浇注温度使浆料充型类似于液态充型,浆料充型过程中卷气,最后在流变压铸试样中出现气孔和硬质点夹杂等缺陷,从而降低了试样抗拉强度。由此可见,适宜的浆料浇注温度在600~620 ℃范围内。

图6 浆料浇注温度为575 ℃时的A390合金流变压铸件

Fig. 6 A390 alloy rheo-diecasting sample for slurry pouring temperature of 575 ℃

图7 A390流变压铸试样抗拉强度与浆料浇注温度的关系

Fig. 7 Relationship between ultimate strength and slurry pouring temperature for A390 rheo-diecasting samples

流变压铸试样密度随浆料浇注温度变化的关系如图8所示。浆料浇注温度低于590 ℃时,流变压铸试样密度低,并且保持在2.5 g/cm3左右。当温度从590 ℃上升到600 ℃,密度急剧上升。而超过此温度后,变化亦不大,保持在2.73 g/cm3左右。由此认为,在本试验条件下,当600 ℃左右的浆料移入压室开始压射之前,温度已降低20 ℃以上,使得固相率急剧上升,从而浆料的流动性变差,压力在传递至型腔的过程中遭到严重削减,因此压铸件密度急剧下降。

图8 流变压铸试样密度与浆料浇注温度的关系

Fig. 8 Relationship between density and slurry pouring temperature for A390 rheo-diecasting samples

图4亦表明,初生Si平均尺寸在580~610 ℃范围内随浆料浇注温度降低而增大的速率缓于610~640 ℃范围内随浆料浇注温度上升的增大速率,这与图7所反映的流变压铸试样力学性能随浆料浇注温度的变化规律(即抗拉强度在580~610 ℃范围内的上升速率明显大于在610~640 ℃范围内的下降速率)不一致。而密度的检测结果(见图8)间接表明在610 ℃后流变压铸试样中孔洞缺陷有一个急剧增加的过程。众所周知,孔洞缺陷会显著降低压铸试样力学性能,从而使其在580~610 ℃范围内的下降速率很大。因此,流变压铸试样力学性能随浆料浇注温度的变化规律是其微观组织和缺陷综合影响的结果。

3 结论

1) A390合金流变压铸试样组织中初生Si主要由尺寸上有明显差别的两部分组成,即浆料制备过程中形成的大块Si(Si1)和压铸模型腔中形成的细小Si(Si3)构成;随着浆料浇注温度从580 ℃升高到640 ℃,初生Si1平均尺寸在34~56 μm范围内呈抛物线变化,在610 ℃附近其尺寸最小,而随温度升高Si3尺寸总体呈增大趋势,但变化不大,稳定在7~15 μm。

2) 浆料浇注温度在600 ℃以下,A390合金浆料流动性显著下降,压铸试样组织中空洞增多,密度存在突变。浆料浇注温度低于590 ℃时,流变压铸试样密度保持在2.5 g/cm3左右;浇注温度在600 ℃以上 时,试样密度保持在2.73 g/cm3左右。

3) 过高和过低的浆料浇注温度都会使流变压铸件力学性能降低,过共晶Al-Si合金A390半固态浆料适宜浇注温度范围为600~620 ℃,此范围内可以得到性能最优的流变压铸试样,其抗拉强度可达260 MPa以上。

REFERENCES

[1] [1] LIANG D, BAYRAKTAR Y, MOIR S A , BARKHUDAROV M, JONES H. Primary silicon segregation during isothermal holding of hypereutectic Al-18.3wt %Si alloy in the freezing range[J]. Scripta Metall Mater, 1994, 31: 363-367.

[2] [1]KAPRANOS P, KIRKWOOD D H, ATKINSON H V, RHEINLANDER J T, BENTZEN J J, TOFT P T, DEBEL C P. Thixoforming of an automotive part in A390 hypereutectic Al-Si alloy[J]. Journal of Material Processing Technology, 2003, 135: 271-277.

[3] [1]BIROL Y. Cooling slope casting and thixoforming of hypereutectic A390 alloy[J]. Journal of Material Processing Technology, 2008, 207: 200-203.

[4] [1]WANG H, NING Z L, YAO X D, DAVIDSON C J, ST.JOHN D. Thixotropic structure formation in A390 hypereutectic Al-Si alloy[C]//Proceedings of the 8th International Conference on Semi-Solid Processing of Alloys and Composites. Limassol, 2004: 553-561.

[5] [1]王 娜, 周志敏. 近液相线半连续铸造过程中A390合金初生硅的形成机理[J]. 中国有色金属学报, 2010, 20(10): 1895-1900.

WANG Na, ZHOU Zhi-min. Forming mechanism of primary Si of A390 alloy during near-liquidus semi-continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1895-1900.

[6] [1] FAN Z. Semisolid metal processing[J]. Int Mater Rev, 2002, 47(2): 49-85.

[7] [1]HAGA T, KAPRANOS P. Simple rheocasting process[J]. Journal of Material Processing Technology, 2002, 130/131: 594-598.

[8] [1]FLEMINGS M C, MARTINEZ R A, FIGUEREDO A M. Metal alloy compositions and process: US, 6645323[P]. 2003.

[9] [1]DEEPAK S, DIRAN A, RATHINDRA D G. SSM processing of hypereutectic Al-Si alloys-An overview[C]//Proc of the 8th Int Conf on Semi-Solid Processing of Alloys and Composites. Limassol, 2004: 855-864.

[10] [1]GABATHULER J P, BUXMANN K. Process for producing a liquid-solid metal alloy phase for further processing as material in the thixotropic state: US 5186236[P]. 1993.

[11] [1]赵君文, 吴树森, 毛有武, 安 萍. 超声振动对过共晶Al-Si合金半固态浆料凝固组织的影响[J]. 中国有色金属学报, 2008, 18(9): 1628-1633.

ZHAO Jun-wen, WU Shu-sen, MAO You-wu, AN Ping. Effect of ultrasonic vibration on microstructure of semi-solid hypereutectic Al-Si alloy slurry[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1628-1633.

[12] [1]POLA A, ARRIGHINI A, ROBERTI R. Effect of ultrasounds treatment on alloys for semisolid application[J]. Solid State Phenomena, 2008, 141/143: 481-486.

[13] [1] ZHAO Jun-wen, WU Shu-sen. Microstructure and mechanical properties of rheo-diecasted A390 alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s754-s757.

[14] [1] 李树索, 赵爱民, 毛卫民, 钟雪友, 韩雅芳. 半固态过共晶Al-Si合金显微组织中近球形α相形成机理的研究[J]. 金属学报, 2000, 36(5): 545-549.

LI Shu-suo, ZHAO Ai-min, MAO Wei-min, ZHONG Xue-you, HAN Ya-fang. Study on forming mechanism of sphere-like α phase in microstructure of semisolid hypereutectic Al-Si alloy[J]. Acta Metallurgica Sinica, 2000, 36(5): 545-549.

[15] [1]GARAT M, BLAIS S, MAENNER L, LASLAZ G. The thixotropic version of the A390 hypereutectic alloy[J]. Hommes et Fonderie, 1999, 298: 14-21.

(编辑 龙怀中)