TiAl合金/40Cr钢摩擦焊接头的组织与力学性能

来源期刊:中国有色金属学报(英文版)2014年第10期

论文作者:董红刚 于连震 高洪明 邓德伟 周文龙 董 闯

文章页码:3126 - 3133

Key words:TiAl alloy; steel; dissimilar metal joining; friction welding; post-weld heat treatment

摘 要:讨论了焊后热处理对TiAl合金与40Cr热轧钢摩擦焊接头显微组织及力学性能的影响。焊态下,钢侧界面层附近发生马氏体转变,界面层中碳原子富集生成TiC,降低了接头的力学性能;TiAl合金侧形成了羽毛状及魏氏体组织。经580 °C和630 °C保温2 h焊后热处理,界面层附近形成回火索氏体组织,碳弥散分布,接头的抗拉强度由焊态时的86 MPa分别提高至395 MPa和330 MPa。焊态下,接头沿界面层断裂;热处理后,接头呈准解理断裂,断裂位置位于TiAl合金侧,距界面层约1 mm。

Abstract: Direct friction welding of TiAl alloy to 40Cr steel rods was conducted, and the microstructure and mechanical properties of the resultant joints in as-welded and post-weld heat treatment (PWHT) states were investigated. The martensitic transformation occurred and brittle TiC phase formed near the interface due to C agglomeration, which degraded the joint strength and increased the microhardness at the interface in as-welded state. Feathery and Widmanstatten structure generated near the interface on TiAl alloy side. After PWHT at 580 °C and 630 °C for 2 h, the sorbite formed and C dispersed at the interface, leading to the increase of the joint strength from 86 MPa in as-welded state to 395 MPa and 330 MPa, respectively. The heat-treated specimen fractured with quasi-cleavage features through the zone 1 mm away from the interface on TiAl alloy side, but the as-welded specimen failed through the interface.

Trans. Nonferrous Met. Soc. China 24(2014) 3126-3133

Hong-gang DONG1,2, Lian-zhen YU1, Hong-ming GAO2, De-wei DENG1, Wen-long ZHOU1, Chuang DONG3

1. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116085, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China;

3. Key Laboratory of Materials Modification of Ministry of Education, Dalian University of Technology, Dalian 116085, China

Received 11 November 2013; accepted 14 March 2014

Abstract: Direct friction welding of TiAl alloy to 40Cr steel rods was conducted, and the microstructure and mechanical properties of the resultant joints in as-welded and post-weld heat treatment (PWHT) states were investigated. The martensitic transformation occurred and brittle TiC phase formed near the interface due to C agglomeration, which degraded the joint strength and increased the microhardness at the interface in as-welded state. Feathery and Widmanstatten structure generated near the interface on TiAl alloy side. After PWHT at 580 °C and 630 °C for 2 h, the sorbite formed and C dispersed at the interface, leading to the increase of the joint strength from 86 MPa in as-welded state to 395 MPa and 330 MPa, respectively. The heat-treated specimen fractured with quasi-cleavage features through the zone 1 mm away from the interface on TiAl alloy side, but the as-welded specimen failed through the interface.

Key words: TiAl alloy; steel; dissimilar metal joining; friction welding; post-weld heat treatment

1 Introduction

TiAl-based alloys are considered to be ideal high-temperature materials widely used in spacecraft, aircraft, shipbuilding and automotive industries, due to their excellent features such as light specific weight, high specific strength, good stiffness, good high-temperature mechanical properties and oxidation resistance [1]. However, the industrial application of TiAl alloy is restricted by its poor weldability, especially in dissimilar metal joining with other materials such as steels.

The mechanical properties of the welded joint between TiAl alloy and steels are often poor by the conventional fusion welding techniques. Large internal stress, thermal cracking and brittle intermetallic compounds could be generated in the dissimilar materials joints, due to the difference of physical properties between TiAl alloy and steel [2].

Brazing and solid state welding are thought suitable for dissimilar joining of TiAl alloy to steels. LI et al [3] discussed the effect of different brazing temperatures on the microstructure of induction brazed joint between TiAl alloy and 42CrMo using Ag-33Cu-4.5Ti alloy filler. The tensile strength of the joint reached 347 MPa when the brazing temperature was 900 °C. NODA et al [4] investigated induction brazing between TiAl alloy and structural steel using Ag-35.2Cu-1.8Ti and Ti-15Cu-15Ni fillers, and found that thick carbide layer formed by reaction between the Ti-based filler and steel substrate, which degraded the tensile strength of the resultant joint. However, no carbide layer existed between the Ag-based filler and steel substrate, and the tensile strength of the joint at ambient temperature reached 320 MPa. DONG et al [5] conducted vacuum brazing of TiAl alloy to 40Cr steel with Ti60Ni22Cu10Zr8 alloy foil and found that the composition of the filler and effective diffusion between the filler and base metals can both affect the shear strength of the joint.

MORIZONO et al [6] carried out diffusion bonding of TiAl alloy to eutectoid steel and the shear strength of the joint bonded at 800 °C reached 160 MPa. However, the joint strength reduced while increasing bonding temperature, due to the growth of reaction layers and formation of microcracks at the interface. HE et al [7] also investigated diffusion bonding of TiAl alloy to 40Cr steel with V-Cu alloy as interlayer and found that the maximum tensile strength of the joint reached 210 MPa, which was higher than the strength of directly diffusion-bonded joint. However, the long thermal cycle time and the complex treatment for the faying surfaces during diffusion welding often restrict the productivity.

Friction welding has apparent advantages in guaranteeing high quality, precision, efficiency and energy saving, especially in dissimilar metal joining. However, the low ductility and fracture toughness of TiAl alloy at ambient temperature make it difficult to join steel by friction welding process [8]. LEE et al [9] explored the mechanical properties of friction welded joints between TiAl and AISI 4140 structural steel, and their results indicated that good joints could be obtained using Cu as insert metal, and the tensile strength of the resultant joint reached 375 MPa. However, microcracks formed at the interface during directly bonding without Cu interlayer, due to the formation of TiC phase. The presence of the microcracks led to the deterioration of joint strength.

It is still a challenge to achieve satisfied joints between TiAl alloy and steels by direct friction welding. Although the tensile strength of the resultant joint could be enhanced by adding interlayer, the entire welding process became more complicated, and the cost would also be increased accordingly. The aim of this work is to conduct direct friction welding of γ-TiAl alloy to as-rolled 40Cr steel, and investigate the microstructure and mechanical properties of the resultant joints in as-welded and post-weld heat treatment states in order to reveal the effect of post-weld heat treatment on improving the joint performance.

2 Experimental

Friction welding of TiAl alloy to as-rolled 40Cr steel rods was carried out using a HSMZ-20 (200 kN capacities) friction welder with a constant rotating speed (1500 r/min) which was designed and manufactured by Harbin Welding Institute, China. The chemical composition of the TiAl alloy was Ti-48Al-2Cr-2Ni (mole fraction, %) and that of 40Cr steel was Fe-0.4C- 1.0Cr-0.7Mn-0.3Si-0.2Ni (mass fraction, %). The tensile strengths of the TiAl alloy and as-rolled 40Cr steel substrates at ambient temperature were 425 MPa and 750 MPa, respectively, and the dimensions of the workpieces were 12 mm in diameter and 100 mm in length. Before welding, the faying surfaces were polished with SiC papers up to grit 1000 and then cleaned with acetone. TiAl alloy and 40Cr steel rods were fixed in spindle and tailstock, respectively, so the TiAl alloy rod rotated with the spindle and the 40Cr steel rod moved axially during welding. After trial welding experiments, the friction pressure and forged pressure were maintained at 186 MPa and 346 MPa, and the burn- off length and forged time were set at 8 mm and 5 s, respectively.

To investigate the effect of post-weld heat treatment (PWHT) on the microstructure and mechanical properties of the resultant joint between TiAl alloy and 40Cr steel, the specimens were heated to 580 °C and 630 °C with heating rate of 15 K/min after welding, and then held in furnace for 2 h, subsequently cooled down to ambient temperature in furnace. The PWHT parameters were determined after considering the heat treatment characters of two base metals, with which the 40Cr steel will be tempered for eliminating residual stress and improving the comprehensive properties [10], but the TiAl alloy will be annealed for removing quenched defects [11].

The tensile strength of the resultant joint was measured by DNS100 universal tensile machine at ambient temperature according to the standard GB/T228.1-2010. Microhardness measurement on each sample was conducted at a load of 2.94 N for 10 s using MVC-1000B microhardness tester. The cross sections of the as-welded and heat-treated joints were polished and then etched for microstructure examination. The TiAl alloy was etched with a mixed solution (V(HF):V(HNO3): V(H2O)=2:4:100), and the 40Cr steel was etched with 4 % natal solution. The distribution of major alloying elements near the interface was detected by a JSM-5600LV scanning electron microscope (SEM) coupled with EDS. And the fracture morphology after tensile test was also examined.

3 Results and discussion

3.1 Mechanical properties

The friction welded joint between TiAl alloy and 40Cr steel rods is shown in Fig. 1(a). During welding, the metal near the faying surface of the workpiece could reach high temperature owing to severe rubbing from high-speed rotating, and then flash was formed from the squeezed hot metals and deformed layers under forged pressure. As shown in Fig. 1(a), the flash consisted of mainly 40Cr steel, and the TiAl alloy deformed slightly because it is with stronger high-temperature strength compared with 40Cr steel [12,13].

Fig. 1 Friction welded joints between TiAl alloy and 40Cr steel rods

Table 1 Post-weld heat treatment parameters and tensile test results

The tensile strength of the as-welded joint reached 86 MPa (Table 1) and failure occurred at the interface between TiAl alloy and 40Cr steel rods. However, after PWHT at 580 °C and 630 °C for 2 h, the tensile strength of the joints No. 2 and No. 3 remarkably increased to 395 MPa and 330 MPa, respectively, and fracture happened through the zone which was about 1 mm away from the interface on TiAl alloy side, as shown in Fig. 1(b). Nevertheless, with increasing the heating temperature from 580 °C to 630 °C, the tensile strength of the joint degraded.

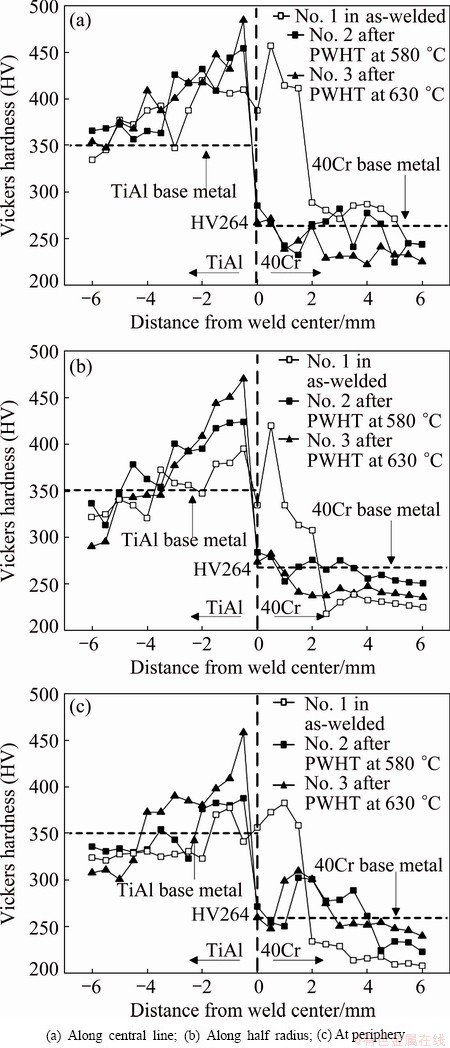

Figure 2 shows the microhardness profiles around the center, half radius and periphery of the joint interface in the workpiece, respectively. It can be seen that, on the TiAl alloy side, the microhardness of the joint after PWHT is higher in the zone within 2 mm close to the interface than in other zones in the as-welded joint. However, on the 40Cr steel side, the microhardness in the as-welded joint is much higher in the zone within 2 mm close to the interface than in other zones in the heat-treated joint; in the zone 2 mm away from the interface, the consequence is reversed. The formation of brittle phases and presence of martensitic structure enhanced the microhardness in the zone within 2 mm close to the interface on steel side, as also reported by LEE et al [9]. And the post-weld heat treatment has greater effect on reducing the microhardness in the area 2 mm away from the interface on steel side, especially at the periphery.

Fig. 2 Distribution of microhardness across joint interface between TiAl alloy and 40Cr steel rods in as-welded and PWHT states

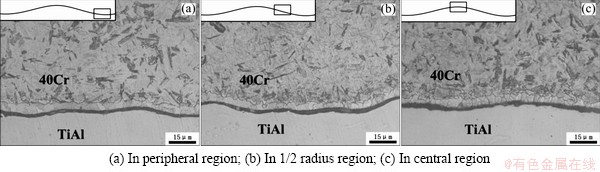

Fig. 3 Microstructure around interface of joint between TiAl alloy and 40Cr steel rods on 40Cr steel side in as-welded state

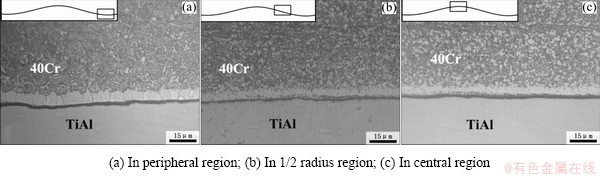

Fig. 4 Microstructure around interface of joint between TiAl alloy and 40Cr steel rods on 40Cr steel side after PWHT at 580 °C

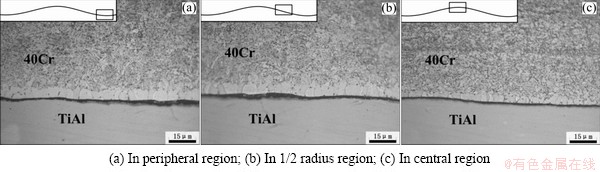

Fig. 5 Microstructure around interface of joint between TiAl alloy and 40Cr steel rods on 40Cr steel side after PWHT at 630 °C

3.2 Microstructure

The microstructures in the central, half radius and peripheral regions of the joints in as-welded and PWHT states are shown in Figs. 3, 4 and 5, respectively. It can be seen in Fig. 3 that martensitic phases and a small amount of ferrites formed near the interface in as-welded state, which caused the microhardness enhancement in this region and the degradation in tensile strength of the resultant joint. During friction welding, the temperature around the interface can reach above A3 temperature, thus the 40Cr steel experiences austenite transformation. Upon cooling, the austenite transformed to other phases like martensite and ferrite because of the diffusion of carbon to the grain boundary and rapid cooling rate [14]. Nevertheless, a great deal of tempered sorbitic structure consisting of ferrite and carbide appeared densely near the interface after PWHT at 580 °C, as illustrated in Fig. 4, which improved the tensile strength of the joint. And the thickness of the interfacial layer and the grain size were larger at periphery in Fig. 4(a), compared with those in half radius and central regions in Figs. 4(b) and 4(c). The reason for this phenomenon is that the heavier plastic deformation and more heat generated at periphery increased the thickness of interfacial layer and coarsened the dynamic recrystallized (DRX) grains, and then resulted in the decrease of microhardness in peripheral region [15]. Additionally, the energy transferred from the periphery to the center during welding, and the heat in peripheral region lost rapidly as the flash formed and contacted the ambient directly, which led to the low temperature in internal region. Meanwhile, the internal metal was forged by large pressure owing to the rapid softening of external materials. Therefore, the DRX grains were refined in central region due to the low temperature and large pressure [16]. It can be seen in Fig. 5 that the interfacial layer at periphery was also thicker than that in the center. And when the PWHT temperature increased to 630 °C, the grains were refined near the interface on 40Cr steel side and carbide distributing in sorbitic phases precipitated uniformly, which could further improve the comprehensive performance of the resultant joint, though the tensile strength of the joint was lower than that after PWHT at 580 °C.

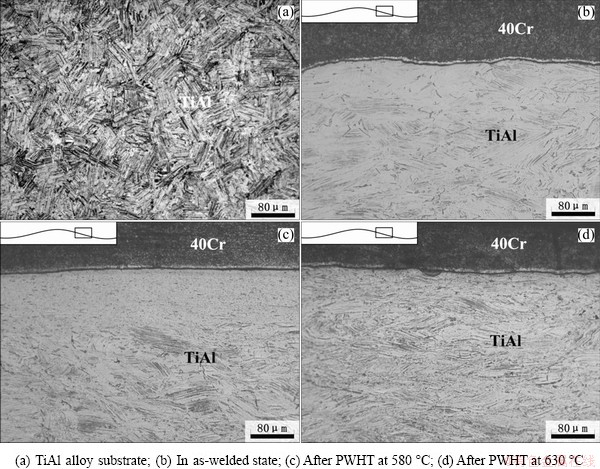

The microstructure around the interface of joints on TiAl alloy side in as-welded and PWHT states is shown in Fig. 6. It can be seen in Fig. 6(a) that the TiAl alloy substrate with dual phase structures consisting of γ-TiAl and a2-Ti3Al arranged interlacedly. The γ/a2 lamellar structure orientated randomly, and the grain size was about 80 μm. Compared with the TiAl alloy substrate, the TiAl alloy near the interface in as-welded state in Fig. 6(b) deformed slightly and had a feathery structure with a small number of laths. According to Ti-Al binary phase diagram, the equilibrium phase of TiAl alloy was a2+γ dual phase structure below 1125 °C [17]. During friction welding, the TiAl alloy entered the a+γ phase region when the temperature exceeded 1125 °C. Then a small portion of α phases transformed to α2 phase, and the remaining α phases could develop to finer feathery structure and Widmanstatten structure due to quenching upon cooling in air after welding, which increased the microhardness near the interface on TiAl alloy side [18]. It can be seen in Fig. 6(c) that a large number of granular recrystallized grains formed in the area within 40 μm close to the interface after PWHT at 580 °C, which significantly increased the microhardness near the interface on TiAl alloy side and enhanced the tensile strength of the joint. However, the lamellar structure near the interface after PWHT at 630 °C orientated along the plastic flow direction in Fig. 6(d) and resulted in the deterioration in tensile strength of joint. This explains why the joint after PWHT at 630 °C for 2 h fractured in the zone 1 mm away from the interface.

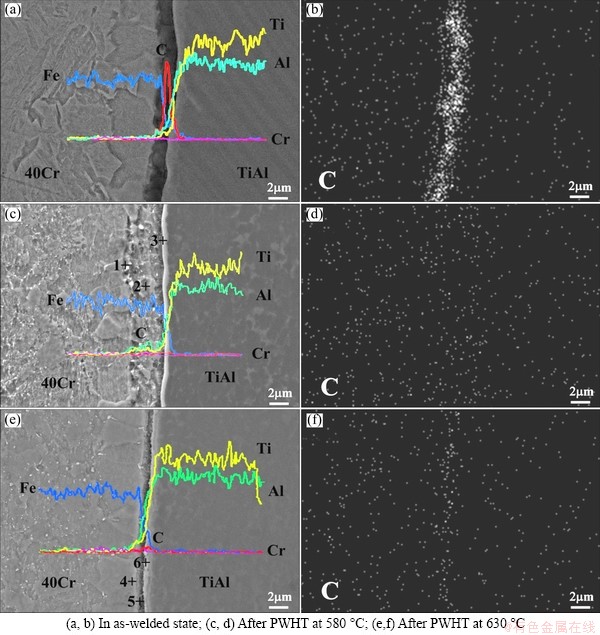

The SEM-EDS analysis results of the joint interface between TiAl alloy and 40Cr steel in as-welded and PWHT states are given in Fig. 7. An apparent interfacial layer formed between the TiAl alloy and steel substrate, as seen in Figs. 7(a), 7(c) and 7(e). Especially, C element agglomerated at the interface in as-welded joint in Fig. 7(b). However, the post-weld heat treatment alleviated and even eliminated the agglomeration of C, as seen in Figs. 7(d) and 7(f). It is well known that Ti is a strong carbide forming element, and the free energy of TiC is lower compared with other carbides, thus Ti combined with agglomerated C to form the brittle TiC phase at the interface, which resulted in the much higher microhardness at the interface in as-welded joint than that after PWHT. The TiC layer was about 2 μm in thickness. Due to the different thermal expansion coefficients among TiC, TiAl alloy and 40Cr steel, the internal stress could be produced in the joint upon rapid cooling after welding. And the internal stress reached a critical value with increasing the thickness of TiC layer, and then caused the formation of microfissure at the interface [19]. Consequently, the existence of brittle TiC phase as well as the martensitic structure caused the degradation in the tensile strength of as-welded joint.

Fig. 6 Microstructure around interface on TiAl alloy side of joints in as-welded and PWHT states

Fig. 7 EDS line analysis across interface in central region, and SEM-EDS map scanning results of element C in different conditions

After PWHT at 580 °C for 2 h, C element did not agglomerate at the interface but distributed uniformly in the joint, as seen in Fig. 7(d). As the tempering temperature increased to 250-400 °C, cementite formed directly in the C agglomerated region, and then the cementite dissolved and tempered sorbite generated. It consisted of finely dispersed alloy carbide particles and ferrite when the tempering temperature reached 500-600 °C [10]. Namely, the C agglomerated region disappeared in PWHT state, avoiding the formation of brittle TiC phase, and tempered sorbite was formed, thus the joint strength was enhanced. However, C element back- diffused at the interface in Fig. 7(f), and carbide could precipitate in this zone when the PWHT temperature increased to 630 °C. Combining the tensile strength of the joints listed in Table 1, it is obvious that the agglomeration of C at the interface controlled the joint strength because carbides like TiC could therefore form and deteriorate the mechanical properties of the resultant joint.

The compositions at different locations around the interface marked in Fig. 7(c) and 7(e) were measured and listed in Table 2. It can be seen that in the joint after PWHT at 580 °C, the intermetallic compounds, TiFe and TiFe2, generated at locations 1 and 2 due to the diffusion of Ti into the interface and the limited solution between Ti and Fe. However, in the joint after PWHT at 630 °C, TiFe2 formed at location 5, and TiC phase existed at location 6 due to the agglomeration of C in this layer.

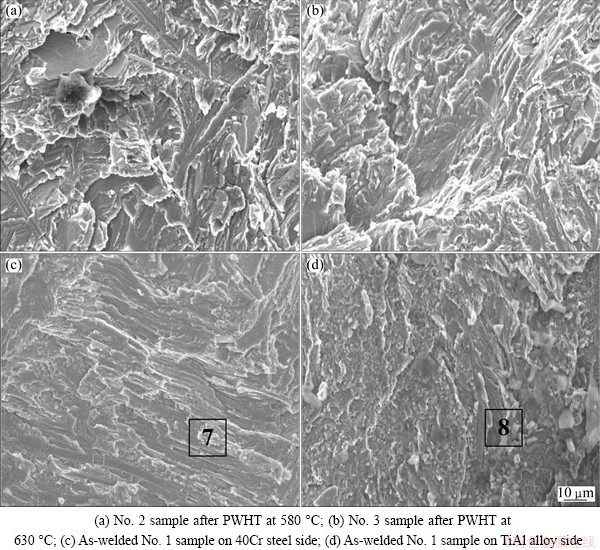

3.3 Fracture morphology

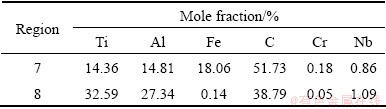

Figure 8 reveals the fracture morphology of samples in as-welded and PWHT states. It can be seen in Figs. 8(a) and 8(b), the quasi-cleavage fractures with tearing ridges were observed on the fractured surfaces of joints after PWHT at 580 °C and 630 °C, respectively. The as-welded joint fractured through the interface shown in Figs. 8(c) and 8(d), revealing brittle features. The compositions at regions 7 and 8 marked in Figs. 8(c) and 8(d) are given in Table 3. It can be seen that C content was much higher than other alloying elements in region 7, suggesting that carbides could generate at the interface on steel side. And the composition in region 8 implies that TiC phases could form at the interface on TiAl alloy side. Therefore, it can be confirmed that the formation of TiC resulted in the deterioration in mechanical properties of the resultant joint.

Table 2 Composition in interfacial layer of joints with different PWHT parameters

Fig. 8 Fracture morphology of samples after tensile test

Table 3 Composition in different regions on as-welded fracture surfaces

4 Conclusions

1) Friction welding between TiAl alloy and as-rolled 40Cr steel rods was conducted, and the microstructure and mechanical properties of the joint in as-welded and PWHT states were investigated. The tensile strength of the as-welded joint was 86 MPa, and fracture happened through the interface during tensile test. The deterioration in tensile strength of as-welded joint resulted from the formation of TiC and martensitic structure near the interface. However, after PWHT at 580 °C and 630 °C for 2 h, the tensile strength of the joints increased to 395 MPa and 330 MPa, respectively, and fracture occurred in the zone 1 mm away from the interface.

2) The microhardness near the interface on TiAl alloy side in PWHT state was higher than that in as-welded state and TiAl alloy substrate. But the microhardness near the interface on steel side in as-welded state was much larger than that in PWHT state, owing to the presence of brittle TiC phase and martensite.

3) Martensite formed near the interface on steel side, and feathery structure with a small amount of Widmanstatten structure generated on TiAl alloy side in as-welded condition. After PWHT, tempered sorbite formed near the interface on steel side, and the grain size was larger in peripheral region than in central region. On TiAl alloy side, the grains were refined near the interface by PWHT; however, the lamellar structure orientated to plastic flow direction, which degraded the tensile strength of the joint.

References

[1] YAMAUCHI M, INUI H, ITO K. High-temperature structural intermetallics [J]. Acta Mater, 2000, 48: 307-322.

[2] THREADGILL P L. The prospects for joining titanium aluminides [J]. Mater Sci Eng A, 1995, 192-193: 640-646.

[3] LI Yu-long, FENG Ji-cai, HE Peng. Vacuum brazing of TiAl to 42CrMo steel with Ag-Cu-Ti [J]. Transactions of Nonferrous Metals Society of China, 2005, 15: 331-334.

[4] NODA T, SHIMIZU T, OKABE M, IIKUBO T. Joining of TiAl and steels by induction brazing [J]. Mater Sci Eng A, 1997, 239-240: 613-618.

[5] DONG H G, YANG Z L, YANG G, DONG C. Vacuum brazing of TiAl alloy to 40Cr steel with Ti60Ni22Cu10Zr8 alloy foil as filler metal [J]. Mater Sci Eng A, 2013, 561: 252-258.

[6] MORIZONO Y, NISHIDA M, CHIBA A. Diffusion bonding of TiAl alloy to eutectoid steel and its interfacial self destruction behavior [J]. Mater Trans, 2004, 45(2): 527-531.

[7] HE P, FENG J C, QIAN Y Y, ZHANG B G. Microstructure and strength of TiAl/40Cr joint diffusion bonded with vanadium-copper filler metal [J]. Transactions of Nonferrous Metals Society of China, 2002, 12: 811-813.

[8] CHEN Y Y, NIU H Z, KONG F T, XIAO S L. Microstructure and fracture toughness of a phase containing TiAl alloy [J]. Intermetallics, 2011, 19: 1405-1410.

[9] LEE W B, KIM Y J, JUNG S B. Effect of copper insert layer on the properties of friction welded joints between TiAl and AISI4140 structural steel [J]. Intermetallics, 2004, 12: 671-678.

[10] ASM International. ASM handbook volume 9: Heating treating [M]. Metals Park, Ohio: American Society for Metals, 1991: 291-293.

[11] WANG B Y, ZHANG S H, WANG T M, CHANG J. Study of the quenched defects in TiAl alloy by positron annihilation [J]. Phys Stat Sol (a), 1997, 163: 33-37.

[12] ZHANG K K, WANG Y L, SHI H X, YU H, LIU S. Isothermal superplastic solid-state welding of 40Cr and QCr0.5, ZQSn6-6-3 [J]. Mater Sci Eng A, 2009, 499: 97-100.

[13] WANG L, LIU Y, ZHANG W, WANG H, LI Q. Optimization of pack parameters for hot deformation of TiAl alloys [J]. Intermetallics, 2011, 19: 68-74.

[14] LEE W B, KIM M G, KOO J M. Friction welding of TiAl and AISI4140 [J]. J Mater Sci, 2004, 39: 1125-1128.

[15] DEY H C, ASHFAQ M, BHADURI A K, PRASAD RAO K. Joining of titanium to 304L stainless steel by friction welding [J]. J Mater Process Technol, 2009, 209: 5862-5870.

[16] DONG L F, ZHONG Y X, MA Q X, YUAN C L, MA L S. Dynamic recrystallization and grain growth behavior of 20SiMn low carbon alloy steel [J]. Tsinghua Sci Technol, 2008, 13(5): 609-613.

[17] SCHUSTER J C, PALM M. Reassessment of the binary aluminum- titanium phase diagram [J]. J Phase Equilib Diff, 2006, 27(3): 255-277.

[18] DEY S R, HAZOTTE A, BOUZY E. Crystallography and phase transformation mechanisms in TiAl-based alloys—A synthesis [J]. Intermetallics, 2009, 17: 1052-1064.

[19] SLUZALEC A. Thermal effects in friction welding [J]. Int J Mech Sci, 1990, 32: 467-478.

董红刚1,2,于连震1,高洪明2,邓德伟1,周文龙1,董 闯3

1. 大连理工大学 材料与科学工程学院,大连116085;

2. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨150001;

3.大连理工大学 三束材料改性教育部重点实验室,大连116085

摘 要:讨论了焊后热处理对TiAl合金与40Cr热轧钢摩擦焊接头显微组织及力学性能的影响。焊态下,钢侧界面层附近发生马氏体转变,界面层中碳原子富集生成TiC,降低了接头的力学性能;TiAl合金侧形成了羽毛状及魏氏体组织。经580 °C和630 °C保温2 h焊后热处理,界面层附近形成回火索氏体组织,碳弥散分布,接头的抗拉强度由焊态时的86 MPa分别提高至395 MPa和330 MPa。焊态下,接头沿界面层断裂;热处理后,接头呈准解理断裂,断裂位置位于TiAl合金侧,距界面层约1 mm。

关键词:TiAl合金;钢;异种金属焊接;摩擦焊;焊后热处理

(Edited by Hua YANG)

Foundation item: Project (51374048) supported by the National Natural Science Foundation of China; Project (2011CB013402) supported by the National Basic Research Program of China; Project (AWPT-Z01) supported by the State Key Laboratory of Advanced Welding and Joining, China

Corresponding author: Hong-gang DONG; Tel: +86-411-84706283; Fax: +86-411-84709284; E-mail: donghg@dlut.edu.cn

DOI: 10.1016/S1003-6326(14)63451-8