文章编号:1004-0609(2011)12-3071-05

纯铜挤扭工艺数值模拟与实验研究

王 成,李 萍,薛克敏,李 晓,章 凯

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:运用有限元模拟软件Msc.Marc对纯铜挤扭工艺变形特征进行研究,分析挤扭变形过程中应变分布以及应变分量的变化趋势。采用自行设计的挤扭模具,在室温下进行了纯铜的一道次挤扭试验。结果表明:变形可分为变形开始、完全充满、逐步挤出3个阶段;应变呈中心低、边缘高的分布;变形过程中正应变分量小,切应变分量较大,变形以剪切变形为主。挤扭过程中存在滑移和孪生两种变形方式;挤扭后试样的硬度得到显著提高,在横截面呈现边缘高、中心低的分布趋势。

关键词:纯铜;挤扭变形;数值模拟;显微组织;显微硬度

中图分类号:TG376 文献标志码:A

Numerical simulation and experimental research on pure copper by twist extrusion

WANG Cheng, LI Ping, XUE Ke-min, LI Xiao, ZHANG Kai

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The finite element simulation about pure copper deformation during twist extrusion (TE) was carried out by the simulation software MSC.Marc, the procedure steps of TE, the distribution of effective strain and the change of strain component were analyzed. The experiment about pure copper at room temperature during TE was carried out using this own die. The results show that the TE deformation can be divided into there steps. The value of the effective strain in the edge area is much larger than that of the center area. The value of the normal strain is extraordinary small, while the shear strain is relative large. There are slipping and twining during the TE process. The hardness of sample significantly increase, the hardness in the edge area is visibly larger than that in the center.

Key words: pure Cu; twist extrusion deformation; numerical simulation; microstructure; microhardness

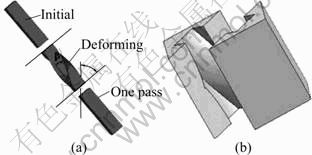

目前,大塑性变形法(SPD)已经成为制备超细晶材料的重要方法[1-4]。挤扭(Twist extrusion, TE)法是一种新型的大塑性变形工艺(见图1),该工艺将非圆形截面试样经螺旋通道挤出。由于一道次变形前后试样横截面的形状和尺寸均不发生改变,可以重复变形以累 积大的塑性变形来达到细化晶粒和提高材料性能的目的[5]。

近年来,国外学者对挤扭工艺开展了相关理论和实验研究,但对挤扭的变形方式和细化机理研究还 不够深入[6-11],国内关于挤扭工艺的研究还少见报 道[12-13]。本文作者运用有限元分析和实验相结合的方法对纯铜的挤扭一道次变形过程进行仿真,分析了挤扭变形过程以及变形时应变分量变化情况;通过纯铜一道次挤扭实验进一步研究挤扭变形后材料组织及性能变化。

图1 挤扭变形原理

Fig.1 Schematic diagram of twist extrusion: (a) Sample; (b) Twist channel

1 有限元模型

采用MSC.Marc有限元软件进行模拟仿真。冲头与凹模采用刚性面简化处理,螺旋通道与直通道连接处采用圆弧过渡,螺旋通道扭转角度为90°,具体尺寸如图2所示。冲头的压下速度为1 mm/s, 模拟过程中不考虑温度的影响。试样与模具的接触均采用库伦摩擦模型,摩擦因数取0.2。

图2 有限元模型

Fig.2 FEM model (mm)

试样为横截面尺寸10 mm×10 mm、长度40 mm的纯铜长方体坯料,材料选用如下Johnson-Cook本构模型:

(1)

(1)

(2)

(2)

式中: 为等效应力;

为等效应力; 为自定义计算系数;

为自定义计算系数; 为等效塑性应变;n为硬化指数;Tm为纯铜熔点;A、B、C、m为实验所得数据,具体值如表1所示。

为等效塑性应变;n为硬化指数;Tm为纯铜熔点;A、B、C、m为实验所得数据,具体值如表1所示。

采用六面体实体单元对坯料进行划分,获得单元数为4 000,节点数4 961。

表1 铜的Johnson-Cook模型参数值

Table 1 Parameters of pure copper to Johnson-Cook mold

2 模拟结果与分析

2.1 变形过程分析

挤扭变形过程决定了试样的应变分布,对晶粒细化和性能改善有重要影响。

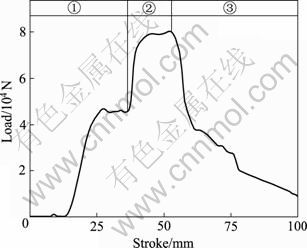

图3所示为一道次挤扭变形过程示意图,可分为3个阶段:第一阶段为变形开始,此时端部被挤入螺旋通道,开始发生剪切变形,挤压力迅速增加(最大为45 kN),直至试样完全充满螺旋通道;第二阶段为试样完全充满螺旋通道阶段后,端部被挤出螺旋通道进入方形通道,挤压力进一步增加(约为80 kN);第三阶段为试样开始被完全挤出,挤压力开始逐渐降低。挤压力—行程曲线如图4所示。

图3 挤扭变形过程

Fig.3 Procedure steps of TE: (a) Initial stage; (b) Steady stage; (c) Final stage

图4 挤压力—行程曲线

Fig.4 Load—stroke curve during TE process

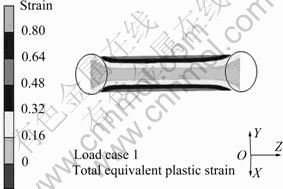

2.2 应变分布

图5所示为挤扭变形后试样纵截面的应变分布图。由图5可知,经一道次挤扭后试样整体发生较大变形。通过纵截面应变分布图分析可知:试样边缘处变形量较中心处大,中心塑性应变为0.16,边缘为0.64。试样两端存在难变形区域(圆圈所示),与冲头接触的左侧一端由于受到摩擦作用,该区金属难以流动,而另一端为自由面,仅边缘受到模具的阻力,近乎刚性平移,变形较小。

图5 纵截面应变分布图

Fig.5 Effective strain distribution of longitudinal section

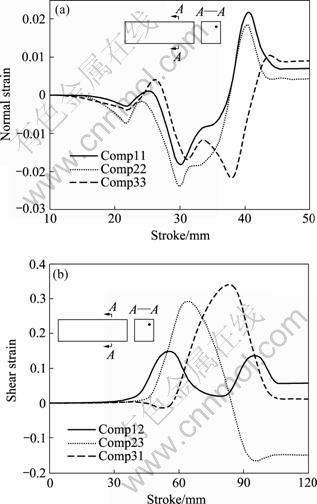

2.3 应变分量

在MSC.Marc中可以提取各个应变分量的变化,包含与法向和切向位移分量相关的comp11,comp22,comp33,comp12,comp23,comp31。前3个分别为垂直于XY,YZ,ZX面的正应变分量,后3个为平行于XY,YZ,ZX面的切应变分量。

按图6所示选取节点(选取原则为避开端部难变形区),正应变分量和切应变分量的变化趋势如图所示。由图6可知,在整个变形过程中3个正应变分量值均较小(最大绝对值均在0.02左右),而切应变值相对较大(最大绝对值分别为0.15、0.30、0.35),这表明挤扭过程以剪切变形为主。而Comp23、31值也说明挤扭过程中剪切变形不仅存在于横截面上,垂直横截面方向上也存在。这与BEYGELZIMER等[14]指出挤扭变形具有两个剪切面的观点是相符合的。

切应变分量的变化与挤扭变形过程有关,变形开始时选取点在直通道内做刚性平移,各切应变分量几乎没有变化,当进入螺旋通道后各应变分量开始发生变化。直至试样完全被挤出螺旋通道后,各应变分量又趋于不变。

图6 节点应变分量的变化

Fig.6 Change of strain component of node: (a) Normal strain; (b) Shear strain

3 实验结果与分析

3.1 实验过程

为了验证模拟分析的可靠性,以及进一步研究挤扭变形的特征及组织演化的规律,试验条件尽量与模拟相一致。在室温下进行纯铜(Cu含量大于99.89%,质量分数)的一道次挤扭试验,对挤扭后试样进行显微组织观察并对试样横截面进行显微硬度测量。

图7所示为挤扭变形前后试样的宏观照片。变形前试样为10 mm×10 mm×40 mm的长方体坯料,经挤扭变形后试样产生了轻度的扭曲,主要是由于挤扭变形过程中试样发生了扭转变形,模具挤出端的矩形通道的长度不足(仅为30 mm),导致试样不能完被全矫正到初始形状,这也从另一个角度反映了挤扭变形的剧烈程度。

图7 挤扭变形前后试样的宏观照片

Fig.7 Photos of samples before TE and after one pass

3.2 显微组织

将试样沿剖切面切开,取横截面进行磨制、抛光、腐蚀观察显微组织,图8(a)所示为挤扭变形前试样组织,基体组织呈近似等轴晶状,晶粒排列均匀规则。图8(b)所示为挤压后试样中心的显微组织,较初始态,晶粒并未发生明显的扭转、破碎变形。根据模拟结果,中心的应变小,变形程度有限,试样中心区域晶粒形状和尺寸变化较小。铜属于FCC晶格金属,晶粒变形以滑移为主,但从图8(b)可以观察到一定数量的孪晶组织(圈中所示),这是由于纯铜属于层错能较低(仅70 mJ/m2)的金属,层错能越低, 位错越容易分解为层错,束集越困难,越难以产生交滑移,越容易发生孪生变形。因此,晶粒细化是孪生与位错滑移共同协调的变形机制。这与文献[15]的结果相似。图8(c)所示为变形后试样的边缘组织,由于该区域变形量较大,晶粒沿扭转方向被严重拉长,等轴晶完全消失,呈纤维状分布的织构组织,由于晶粒完全变形成纤维状,因此,观察不到孪晶。

图8 挤扭变形前后显微组织图

Fig.8 Microstructures of samples before and after TE: (a) Initial; (b) Center; (c) Edge

3.3 显微硬度

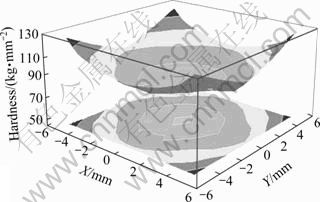

图9所示为挤扭后试样横截面硬度实测值的三维分布图。纯铜初始硬度为62.7。由图9可以看出,挤扭变形后中心处硬度值最小(约为87),边缘硬度值大,在4个棱角处达到最大(约为130)。硬度的增加主要与变形量有关,变形导致晶粒细化和加工硬化,由于挤扭过程中晶粒通过滑移和孪生的变形方式,晶粒细化导致硬度提高。并且随着变形的加剧,其内部产生较多位错,形成了缠结,并构成胞状亚结构,位错之间相互干扰, 使滑移困难,变形抗力增加导致金属硬化。这也解释了剪切应变大的区域硬度值也较高的原因。

从试样横截面组织形貌以及硬度分布,结合模拟结果分析可知,应变量大的区域组织变形越剧烈,硬度值也得到显著提高,应变量小的区域则变化不明显。模拟分析很好地解释了实验结果。

图9 挤扭后试样横截面硬度实测值的三维分布图

Fig.9 Measured microhardness profile of cross-section of samples after one pass TE

4 结论

1) 挤扭变形过程分为3个阶段,即变形开始、完全充满、逐步挤出阶段;挤扭变形后,试样等效塑性应变呈中心低(0.16)、边缘高(0.64)的分布;挤扭变形过程中正应变分量较小,而切应变分量相对较大。

2) 挤扭后,试样边缘晶粒变形程度大于中心处的,边缘处硬度(130)高于中心处硬度(87);挤扭变形过程中,存在滑移和孪生两种变形方式,纯铜晶粒变形为两种变形方式的共同协调机制。

REFERENCES

[1] SEGAL V M. Severe plastic deformation: simple shear versus pure shear[J]. Materials Science and Engineering A, 2002, 338: 331-344.

[2] 李 萍, 黄科帅, 薛克敏, 周明智, 韩国民. 纯铝粉末多孔烧结材料等通道转角挤压[J]. 中国有色金属学报, 2009, 19(5): 881-886.

LI Ping, HUANG Ke-shuai, XUE Ke-min, ZHOU Ming-zhi, HAN Guo-min. Equal channel angular pressing of pure Al powder sintered material[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 881-886.

[3] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Progress in Materials Science, 2000, 45: 103-189.

[4] 周明智, 薛克敏, 李 萍. 粉末多孔材料等径角挤压过程热力耦合有限元数值分析[J]. 中国有色金属学报, 2006, 16(9): 1510-1516.

ZHOU Ming-zhi, XUE Ke-min, LI Ping. Coupled thermomechanical finite element analysis of metal with porosities during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1510-1516.

[5] BEYGELZIMER Y, VARYUKHIN V, SYNKOV S, DRLOV D. Useful properties of twist extrusion[J]. Material Science and Engineering A, 2009, 503(1/2): 14-17.

[6] BEYGELZIMER Y, RESHETOV A, SYNKOV S. Kinematics of metal flow during twist extrusion investigated with a new experimental method [J]. Journal Materials Processing Technology, 2008, 209(7): 3650-3656.

[7] VARYUKHIN V, BEYGELZIMER Y, SYNKOV S, PROKOFEVA O, KULAQIN R. Application of twist extrusion[J]. Materials Science Forum, 2006, 503/504: 335-340.

[8] AKBARIMOUSAVI S A A. Influence of strain accumulation on microstructure of aluminum 1100 in the twist extrusion[J]. International Journal of Modern Physics B, 2008, 22(18/19): 2858-2865.

[9] BERTA M, ORLOV D, PRANGNELL P. Grain refinement response during twist extrusion of an Al-0.13% Mg alloy[J]. International Journal of Materials Research, 2007, 98: 3200-3204

[10] AKBARIMOUSAVI S A A, SHAHAB A R, MASTOORI M. Computational study of Ti-6Al-4V flow behaviors during the twist extrusion process[J]. Materials and Design, 2008, 29: 1316-1329.

[11] ORLOV D, BEYGELZIMER Y, SYNKOV S, et al. Evolution of microstructure and hardness in pure Al by twist extrusion[J]. Materials Transactions, 2008, 49(1): 2-6.

[12] 薛克敏, 吴战立, 李 萍, 王晓溪, 贾建磊. 纯铝等径角挤扭新工艺数值模拟及实验研究[J]. 中国机械工程, 2010, 21(12): 1485-1489.

XUE Ke-min, WU Zhan-li, LI Ping, WANG Xiao-xi, JIA Jian-lei. Simulate and experiment research on a new technique named equal channel angular extrusion and twist prepared by pure aluminum[J]. China Mechanical Engineering, 2010, 21(12): 1485-1489.

[13] 薛克敏, 王晓溪, 李 萍. 超细晶材料制备新工艺—挤扭[J]. 塑性工程学报, 2009, 16(5): 130-136.

XUE Ke-min, WANG Xiao-xi, LI Ping. A new technique for preparing bulk ultrafine-grained materials though twist extrusion[J]. Journal of Plasticity Engineering, 2009, 16(5): 130-136.

[14] BEYGELZIMER Y, VARYUKHIN V, SYNKOV S. Shears, vortice, and mixing during twist extrusion[J]. International Journal of Material Forming, 2008, 1(s1): 443-446.

[15] 汪建敏, 周孔亢, 陆 晋, 许晓静, 姜银方. 层错能在剧烈剪切变形时对影响[J]. 机械工程学报, 2008, 44(11): 126-131.

WANG Jian-min, ZHOU Kong-kang, LU Jin, XU Xiao-jing, JIANG Yin-fang. Influence of stack fault energy on grain refining during sever shear deforming[J]. Chinese Journal of Mechanical Engineering, 2008, 44(12): 126-131.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50875072);霍英东教育基金会资助项目(121053);安徽省优秀青年科技基金计划(10040606Y21)

收稿日期:2010-09-07;修订日期:2011-10-15

通信作者:李 萍,教授,博士;电话:0551-2904758;E-mail: cisi_1314@126.com