不同淬火工艺对7075铝合金厚板残余应力的影响

龚海,吴运新,廖凯

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:对7075铝合金厚板进行固溶处理后,分别采用浸没淬火和喷淋淬火再进行预拉伸处理。运用裂纹柔度法检测2种淬火板和相应的预拉伸板内部的残余应力,研究不同淬火工艺对铝厚板残余应力产生和预拉伸后重新分布的影响。研究结果表明:淬火速率越大,铝厚板内产生的残余应力也越大,浸没淬火试样的残余压应力和残余拉应力分别比喷淋淬火试样的残余压应力和残余拉应力大60%和73.6%;经过预拉伸处理后,淬火应力得到极大消减,残余应力被控制在±20 MPa以内,满足后续加工的要求;当拉伸量为1.8%,2.2%和2.5%时,残余应力的消减效果相当。

关键词:残余应力;裂纹柔度法;铝合金;预拉伸

中图分类号:TG146.2;TG166.3 文献标志码:A 文章编号:1672-7207(2010)04-1354-06

Influence of different quenching techniques on residual stress of

7075 aluminum alloy thick-plate

GONG Hai, WU Yun-xin, LIAO Kai

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: After solution treatment, 7075 aluminum alloy thick-plates were quenched by immersion and spraying separately, then treated by pre-stretching process. Residual stresses of immerging quenched plates and spraying quenched plates, as well as stresses of corresponding pre-stretched plates were measured with crack compliance method. The influence of different quenching techniques on residual stress developing and redistributing after pre-stretching of 7075 aluminum alloy thick-plate were studied. The results show that the faster the quenching speed, the larger the residual stress of aluminum alloy thick-plate. The compressive stress and tensile stress of immerging quenched plates are 61% and 73.6% larger than those of spraying quenched plates, respectively, and after pre-stretching process, the residual stress decreases to the range of -20—20 MPa, which satisfies the machining requirement. Furthermore, for these stretching ratios of 1.8%, 2.2% and 2.5%, the differences of the residual stress relieving effect are quite small.

Key words:residual stress; crack compliance method; aluminum alloy; pre-stretch

航空工业的发展对高强航空铝材的性能提出了越来越高的要求,例如要求获得极高的比强度和比刚度、均匀的厚板组织和机械性能、较小的残余应力等[1]。淬火及时效作为一种综合热处理工艺,可用来提高铝合金的强度性能。淬火工艺虽然能够大大提高铝合金厚板的机械性能,但同时不可避免地使板材内部产生较高残余应力。残余应力的存在对材料的机械性能和材料抗疲劳、抗腐蚀特性产生极大影响,降低了材料的寿命和稳定性,这直接影响了厚板的后续再加工稳定性[1-2],因此,有必要研究热处理工艺对铝厚板残余应力的影响。Prime等[3-5]运用裂纹柔度法对美铝(ALCOA)产品进行了残余应力测试,得到了淬火板和相应的预拉伸板内部的残余应力分布;Koc等[6]运用有限元法,对铝厚板的淬火过程、预拉伸和机械压缩等应力消减过程进行了模拟,预测了铝厚板内部的淬火应力和经过应力消减工艺后的残余应力水平。王秋成等[7-11]对淬火铝厚板和预拉伸板内部残余应力分布进行了类似的研究。然而,人们对采用不同淬火工艺的淬火板、不同拉伸量的预拉伸板内部的残余应力状况的研究较少。本文作者对铝厚板生产中常用的2种淬火方式即浸没淬火和喷淋淬火进行对比研究,分析不同的淬火工艺对残余应力分布、预拉伸处理后残余应力重新分布的影响。

1 实验

1.1 实验条件

测试对象为国产7075铝合金轧制板,板材尺寸(长×宽×厚)为1 200 mm×220 mm×50 mm,材料的成分(质量分数)为:Zn(5.2%~5.7%),Mn(1.9%~2.6%),Cu(1.2%~2.3%),Al(余量)。固溶处理后,分别采用浸没淬火和喷淋淬火,淬火温度为475 ℃,淬火介质为25 ℃自来水。浸没淬火采取直接将铝板投入水池中的方法,水池中的水保持一定的流量以确保水温不会上升过高;喷淋淬火采取铝板侧立放置、从两边喷水的方法,在水池两侧壁各安置一组喷嘴,每组上下各一排,每排9个喷嘴呈对称分布,喷水压力为0.34 MPa,水流量约为136 L/min,喷射面形状为圆锥形。淬火完成后,将板材沿长度方向截为长度为400和800 mm的2块板材,长度为400 mm的板材可视为保持了淬火应力状态,对长度为800 mm的板材继续进行预拉伸处理,拉伸实验在5 MN液压拉伸机上进行。为了研究拉伸量对应力消减效果的影响,做了3个不同拉伸量(1.8%,2.2%和2.5%)的预拉伸板。采用裂纹柔度法检测不同状态铝厚板内部的残余应力。考虑到铝厚板淬火过程中存在边缘效应[12],试样从相应的淬火板和预拉伸板的长度和宽度中间部位应力分布均匀区截取,尺寸均为120 mm×120 mm×50 mm(长×宽×厚),切割加工在锯床上进行。在切割过程中,采取慢速切割,以减少加工对试件初始应力的影响。

1.2 测试原理与方法

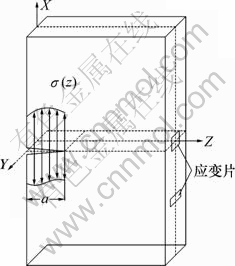

裂纹柔度法的测量原理是:在被测量物体表面引入一条深度逐渐增加的裂纹来释放残余应力[4],通过测量物体表面特定点的应变来计算残余应力。图1所示为测试原理图。设板材为均匀连续材料,残余应力沿板的长度X方向、宽度Y方向的分布基本不变,只沿厚度Z方向存在较大的应力梯度,且其分布为厚度坐标Z的函数,可以表示为一个展开的级数形式:

(1)

(1)

式中:n为插值函数的阶数;Ai为待定系数A的分量;Pi(z)为插值函数P的分量。Pi(z)的选择必须满足板内残余应力的力和力矩自平衡条件,本文中采用2~9阶Legendre级数。为了确定待定系数Ai,先要计算图1中所示应变片位置上的应变随裂纹深度aj变化的响应值Cij (称为柔度函数)。根据叠加原理,该应变可以表示为:

(2)

(2)

在计算Ai时,为了减少计算误差,将根据柔度函数计算得到的应变与实验得到的m次应变读数采用最小二乘法拟合,得到:

(3)

(3)

其中: ;

; 为测试得到的裂纹深度为aj时的应变;

为测试得到的裂纹深度为aj时的应变; 为计算得到的裂纹深度为aj、插值函数为Pj时的应变。

为计算得到的裂纹深度为aj、插值函数为Pj时的应变。

通过求解式(3),可以得到方程(1)的系数Ai,即

(4)

(4)

图1 裂纹柔度法的应变测量

Fig.1 Strain measurements of crack compliance method

采用MARC有限元软件计算柔度函数,根据试样的对称性,以线切割的切缝为对称轴取半个试样划分网格,采用8节点平面单元QUAD8,靠近切缝区域网格尺寸为0.2 mm×1.0 mm,远离切缝端网格尺寸为1 mm×1 mm。材料的弹性模量取71 GPa,泊松比取0.33。在模型内部加载初始应力,约束切缝边的所有自由度,采用生死单元法逐渐去除切缝位置的单元来模拟裂纹的产生。实验中,采用DK77线切割机引入裂纹,电极丝为直径0.18 mm钼丝,进给速度为 1 mm/min,加工后切缝宽约为0.5 mm。选用BX120-5AA应变片,栅(长×宽)为5 mm×3 mm,切割位置和应变片贴片位置如图1所示,为了保证数据的可靠性,贴片位置并排安置3片应变片,工作应变片和补偿片接入静态应变仪YE2533组成1/4电桥,沿板厚度方向切割深度每增加1mm,等待数据稳定后记录应变数据。方块试样完成轧向的测试后,直接取切割后试样的一半用于测试横向的应变数据。

2 实验结果

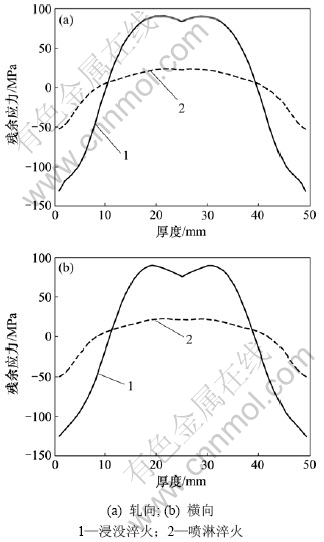

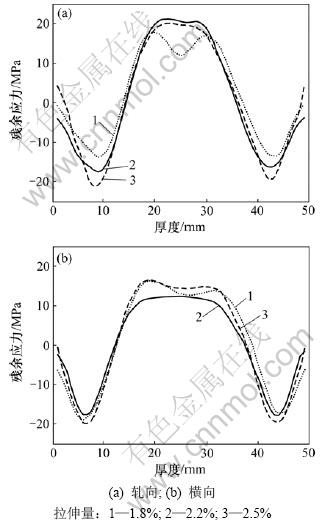

图2所示为测试得到的浸没淬火板和喷淋淬火板内部残余应力沿板厚方向的分布。从应力分布曲线可以看出:铝厚板经过淬火处理后,板内残余应力表现出外压内拉的分布。浸没淬火板表层的压应力峰值 (绝对值)达到130.42 MPa,心部的拉应力峰值达到 90.12 MPa,压应力绝对值略大于拉应力;而喷淋淬火板表层的压应力峰值为52.1 MPa,心部的拉应力峰值为23.8 MPa。浸没淬火板的压应力和拉应力比喷淋淬火板的压应力和拉应力分别大60%和73.6%。可见,浸没淬火和喷淋淬火由于淬火速率的差异,使得淬火残余应力相差较大。图2(b)所示为2种淬火板内横向残余应力沿板厚方向的分布,可以看出:横向残余应力在厚度方向的分布规律与轧制方向的相似,只是值略小。

图2 铝厚板内部淬火残余应力

Fig.2 Residual stresses in aluminum alloy thick-plates after quenching

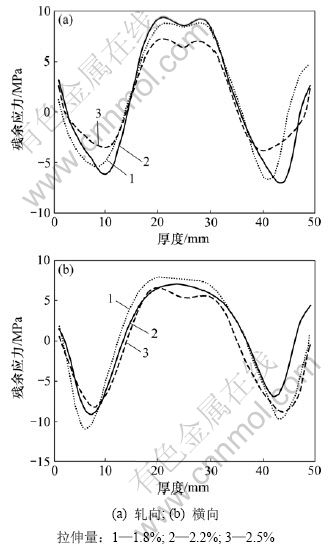

图3和图4所示分别为浸没淬火-预拉伸板和喷淋淬 火-预拉伸板内部残余应力沿板厚方向的分布,拉伸量分别为:1.8%,2.2%和2.5%。从图3和4可以看出:预拉伸处理后的浸没淬火板内残余应力,不论是轧向应力还是横向应力,均已被消减至±20 MPa以内,而预拉伸处理后的喷淋淬火板内的残余应力,轧向应力和横向应力则均被消减至±10 MPa以内。与图2对比可以看出:经过预拉伸处理后,大幅度地消减了板内的淬火应力,且淬火应力越大消减效果越明显。浸没淬火板中压应力的消减率达到80%以上,拉应力的消减率接近80%,而喷淋淬火板中压应力消减率达到80%,拉应力的消减率接近70%。

图3 不同拉伸量时的浸没淬火-预拉伸板内部残余应力

Fig.3 Residual stresses in immerging quenched plates after pre-stretching with different stretching ratios

图4 不同拉伸量时的喷淋淬火-预拉伸板内部残余应力

Fig.4 Residual stresses in spraying quenched plates after pre-stretching with different stretching ratios

对于喷淋淬火-预拉伸板,随着拉伸量的增大,残余应力消减效果增加,预拉伸2.5%时的残余应力明显低于预拉伸1.8%的板材的残余应力(图4)。对于浸没淬火-预拉伸板(图3),轧向应力消减效果以拉伸量为1.8%的板材最好,而横向应力消减效果以拉伸量为2.2%的板材最好,当拉伸量增大到2.5%左右时,残余应力反而略大于预拉伸1.8%的板材的拉伸应力。这可以从2个方面来解释:第一,与剧烈的浸没淬火相比,喷淋淬火获得的残余应力分布较均匀,在预拉伸阶段,残余应力分布的均匀性使得预残余处理后,喷淋淬火板表现出随着拉伸量增大其应力减小的规律,而浸没淬火板则没表现出此规律;第二,随着拉伸量的增加,塑性变形不均匀性出现的概率也随之增加,使得应力出现回升,当板内残余应力较大时,这种规律表现得更为明显。

采用同种淬火工艺的预拉伸板,比较不同拉伸量所对应的应力可以看出:不论哪种淬火板,也不论轧向应力还是横向应力,拉伸量不同引起的应力差值都在5 MPa以内,即应力消减的实际效果相当。可见,1.8%~2.5%的拉伸量都是适宜的。

3 讨论

铝厚板淬火应力主要来自热应力。淬火急冷时,由于工件表层和心部的冷却状态不同而有温度差,随着时间的推移产生热应力以及最终状态的残余应力。淬火过程中,当工件表层温度和心部温度之差达到最大时,其外表和心部的拉应力和压应力也随之达到最大值。温差达到最大值后,随着温度差减小,应力状态在淬火后期发生反向,最终得到外表为压应力,心部为拉应力的状态[13]。冷却时的温度差对残余应力起支配作用。因此,通过合理控制淬火速率,可以降低淬火过程中工件表层和心部的最大温差,从而减小残余应力。

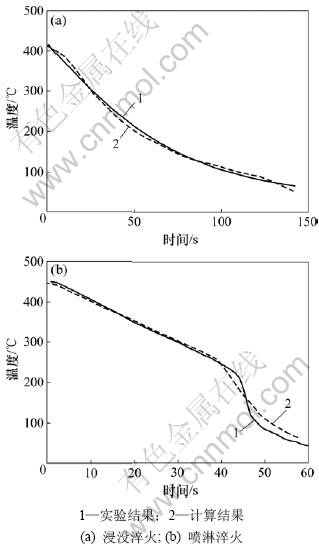

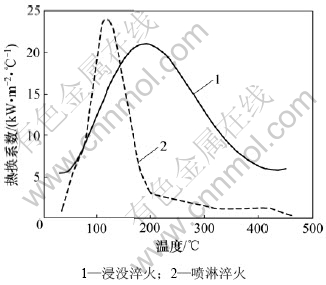

为了分析2种淬火方式引起的淬火应力差异,对铝厚板淬火过程进行数值模拟。基于热场的相关理论,通过测试淬火温降曲线,得到铝厚板淬火过程的换热系数。在模拟过程中所用到的其他热物理参数和力学性能参数(如比热容、热导率等)均随温度变化而变 化[14]。图5所示为铝厚板浸没淬火和喷淋淬火时板厚中心的温降曲线。从图5可以看出:二者具有很好的一致性,充分验证了模型的准确性。对于喷淋淬火,测试条件与实际淬火工况相同,对于浸没淬火,为了便于测试,采用端淬的方法,在淬火过程中,热电偶插入铝板心部测试温度变化。

图6所示为计算得到的铝厚板换热系数曲线。从图6可以看出:2种淬火方式的换热系数峰值出现在不同的温度段,浸没淬火时换热系数峰值出现在150~250 ℃,而喷淋淬火时换热系数峰值出现在100~200 ℃。可见:浸没淬火时,铝板能更快地进入核态换热阶段。对于温度高于200 ℃的高温阶段,浸没淬火的换热系数值明显高于喷淋淬火的换热系数;淬火前期,浸没淬火冷却速度更大,程度更剧烈,而喷淋淬火相对比较缓和。

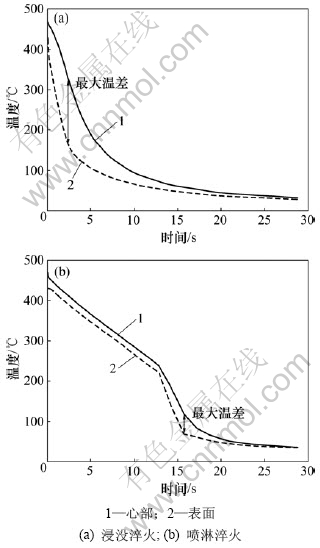

以反求得到的界面换热系数作为对流换热边界条件,对浸没淬火和喷淋淬火进行仿真,得到了淬火温度场。图7所示为仿真得到的铝厚板表层和心部的淬火温度场曲线。可见:采用浸没淬火时,铝板表层和心部的最大温差达到167 ℃;采用喷淋淬火时,最大温差仅为50 ℃。在喷淋淬火过程中,铝板表面和心部的温度差较小且基本保持一致,而浸没淬火初期铝板表面和心部存在很大的温度差;随时间推移,温度差逐渐变小。可见:在淬火温度、淬火介质、介质温度等淬火条件相同的情况下,浸没淬火能在极短的时间内使铝厚板温度降低到常温,但心部温度始终高于表层温度直至铝板接近常温,从而导致较大的淬火残余应力。而喷淋淬火采用高压喷射淬火介质,使其强烈地喷射在铝板表面,水流从铝板表面均匀地带走热量,因此,铝板表层温度下降程度没有浸没淬火那么迅速,使得铝厚板的表层和心部的温度梯度也较小,从而大大减小了淬火残余应力的产生。

图5 淬火温度场曲线

Fig.5 Temperature curves of quenching

图6 换热系数曲线

Fig.6 Curves of heat transfer coefficient

图7 仿真得到的淬火温度场曲线

Fig.7 Simulated temperature curves of quenching

喷淋淬火通过控制喷射淬火介质的压力、温度和流量等来控制工件淬火过程中的冷却速率。而浸没淬火只能通过改变介质温度、浓度以及通过搅拌来控制淬火介质的冷却速度,不能控制冷却过程的冷却速率变化。与浸没淬火相比,采用喷淋淬火能使淬火残余应力减少60%~73.6%,因此,喷淋淬火对于减小淬火残余应力具有较大的实用价值。然而,7×××铝合金存在淬火敏感性,其力学性能随淬火速率的减小而降 低[15]。因此,要降低淬火残余应力,就必须在保证铝厚板其他机械性能的前提下,合理控制淬火速率。在铝厚板其他机械性能满足工业要求的条件下,合理选择喷淋淬火参数,可以获得较小的残余应力。

4 结论

(1) 淬火铝厚板内部残余应力呈外压内拉分布,淬火速率越大,产生的残余应力越大。

(2) 预拉伸能大幅度消减淬火冷却速度引起的残余应力差异,经过1.8%~2.5%变形量的预拉伸后,浸没淬火板和喷淋淬火板内部残余应力分别降至±20 MPa和±10 MPa,满足后续加工要求。

(3) 当拉伸量为1.8%~2.5%时,应力消减效果相差不大,可见该范围内的拉伸量都是可取的。

(4) 淬火速率引起的残余应力差异,源自淬火过程中工件表层和心部的温度梯度差异,选择合理的淬火参数可以有效控制淬火残余应力。

参考文献:

[1] 柯映林, 董辉跃. 7075铝合金厚板预拉伸模拟分析及其在淬火残余应力消除中的应用[J]. 中国有色金属学报, 2004, 14(4): 639-645.

KE Ying-lin, DONG Hui-yue. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick-plate[J]. The Chinese Journal of Nonferrous Metal, 2004, 14(4): 639-645.

[2] 王秋成, 柯映林. 航空高强度铝合金残余应力的抑制与消除[J]. 航空材料学报, 2002, 22(3): 59-62.

WANG Qiu-cheng, KE Ying-lin. Control and relief of residual stresses in high-strength aluminum alloy parts for aerospace industry[J]. Journal of Aeronautical Materials, 2002, 22(3): 59-62.

[3] Prime M B, Gnaupel-Herold T. Residual stress measurements in a thick, dissimilar aluminium alloy friction stir weld[J]. Acta Materialia, 2006, 54: 4013-4021.

[4] Prime M B, Hill M R. Residual stress, stress relief, and inhomogeneity in aluminum plate[J]. Scripta Materialia, 2000, 46(1): 77-82.

[5] Prime M B, Hill M R. Uncertainty analysis, model error, and order selection for series-expanded, residual-stress inverse solutions[J]. Journal of Engineering Materials and Technology, 2006, 11: 175-185.

[6] Koc M, Culp J, Altan T. Prediction of residual stresses in quenched aluminum blocks and their reduction through cold working processes[J]. Journal of Materials Processing Technology, 2006, 174: 342-354.

[7] 王秋成, 柯映林, 邢鸿燕. 板类构件内部残余应力测试技术研究[J]. 浙江大学学报: 工学版, 2005, 39(3): 381-384.

WANG Qiu-cheng, KE Ying-lin, XING Hong-yan. Study on measurement method of interior stress distributions in engineering rolled-plates[J]. Journal of Zhejiang University: Engineering Science, 2005, 39(3): 381-384.

[8] 王秋成, 柯映林, 章巧芳. 7075铝合金板材残余应力深度梯度的评估[J]. 航空学报, 2003, 24(4): 336-338.

WANG Qiu-cheng, KE Ying-lin, ZHANG Qiao-fang. Evaluation of residual stress depth profiling in 7075 aluminum alloy plates[J]. Acta Aeronautica et Astronautica Sinica, 2003, 24(4): 336-338.

[9] 王树宏, 左敦稳, 润长生, 等. LY12, B95和7050铝合金预拉伸厚板内部残余应力分布特征评估与分析[J]. 材料工程, 2004, 10: 32-35.

WANG Shu-hong, ZUO Dun-wen, RUN Chang-sheng, et al. Evaluation and comparison of residual stress in thick pre-stretched aluminum plates of LY12, B95 and 7050[J]. Material Engineering, 2004, 10: 32-35.

[10] 王树宏. 航空铝合金厚板初始残余应力及其对铣削变形影响的基础研究[D]. 南京: 南京航空航天大学机电工程学院, 2005: 12-20.

WANG Shu-hong. Study on initial residual stresses and their effects on milling distortion for thick aero aluminium alloy plate[D]. Nanjing: Nanjing University of Aeronautics and Astronautic. School of Mechanical and Electronic Engineering, 2005: 12-20.

[11] 王树宏, 马康民, 马俊. 预拉伸铝合金板7075T7351内部残余应力分布测试[J]. 空军工程大学学报: 自然科学版, 2004, 5(3): 19-21.

WANG Shu-hong, MA Kang-min, MA Jun. Method of measuring the residual stress distribution in pre-stretched aluminum alloy plate 7075T7351[J]. Journal of Air Force Engineering University: Natural Science Edition, 2004, 5(3): 19-21.

[12] 胡少虬, 曾苏民. 无相变合金淬火热应力演变机理的理论模型: (1)角端和边缘淬火热应力模型与淬火角端效应[J]. 稀有金属材料与工程, 2006, 35(4): 538-541.

HU Shao-qiu, ZENG Su-min. The theoretical model of the thermal stress evolution mechanism during quenching of no phase change alloy: (1)the corner and edge model for thermal stress during quenching and the corner effect during quenching[J]. Rare Metal Materials and Engineering, 2006, 35(4): 538-541.

[13] 米谷茂. 残余应力的产生和对策[M]. 北京: 机械工业出版社, 1983: 53-61.

MI Gu-mao. Formation and countermeasure of residual stress[M]. Beijing: China Machine Press, 1983: 53-61.

[14] 姚灿阳. 7050铝合金厚板淬火温度场及内应力场的数值模拟研究[D]. 长沙: 中南大学机电工程学院, 2007: 23-28.

YAO Can-yang. Numerical simulation of quench temperature field and internal stress field of aluminium alloy 7075 thick plate[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 23-28.

[15] 张新明, 张翀, 刘胜胆, 等. 轧制变形量对7A55铝合金淬火敏感性的影响[J]. 中南大学学报: 自然科学版, 2007, 38(4): 589-594.

ZHANG Xin-ming, ZHANG Chong, LIU Sheng-dan, et al. Effect of rolling reduction on quench sensitivity of aluminium alloy 7A55[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 589-594.

收稿日期:2009-08-14;修回日期:2009-11-10

基金项目:国家重点基础研究发展计划项目(2005CB623708)

通信作者:龚海(1982-),男,湖南新化人,博士研究生,从事铝厚板残余应力检测和消减研究;电话:0731-88877840;E-mail: gonghai88@yahoo.com.cn

(编辑 赵俊)