文章编号:1004-0609(2008)06-0959-08

微量元素对高强铝合金焊缝组织和力学性能的影响

许良红,田志凌,彭 云,张晓牧

(钢铁研究总院 先进钢铁流程及材料国家重点实验室,北京100081)

摘 要:在ER2319焊丝的基础上,分别添加少量Ce、Cr及Mn元素制备了3种焊丝。采用光学显微镜、扫描电镜和能谱分析技术研究微量元素Ce、Cr和Mn对MIG焊缝组织和性能的影响。结果表明:Ce能够细化二次枝晶间距,但Ce易与Ti、Zr相互反应在晶界生成块状硬而脆的AlCuCeTiZrV复杂金属间化合物,降低了Ti和Zr的异质形核作用,使焊缝组织成柱态。而Cr和Mn则能促进Al3Ti、Al3Zr以及复合析出物Al3(Zr, Ti)的析出,增加这些颗粒在高温条件下的稳定性,能够显著细化焊缝晶粒和晶界共晶相,提升接头的力学性能。但Mn的含量达到0.58%时,焊缝中心容易形成粗大树枝晶。

关键词:高强铝合金;微量元素;形核;等轴晶

中图分类号:TG 457.14 文献标识码:A

Effects of trace elements on microstructure and

mechanical properties of high strength aluminum alloy welds

XU Liang-hong, TIAN Zhi-ling, PENG Yun, ZHANG Xiao-mu

(State Key Laboratory of Advanced Steel Processes and Products,

Centre Iron & Steel Research Institute, Beijing 100081, China)

Abstract: On the basis of ER2319 filler wire, three filler wires were prepared by adding Ce, Cr and Mn elements. The effects of these trace elements on the microstructure and mechanical properties of MIG welds were investigated by optical microscopy, scanning electron microscopy and energy dispersive spectrum. The results indicate that the addition of Ce can refine the second dendrite arm spacing, but it is easy to form AlCuCeTiZrV complex intermetallic compound at the grain boundary, which will reduce the refinement efficiency of the Ti and Zr inoculants, and make the morphology of the welds microstructure to be columnar. Cr and Mn are proved to improve the refinement efficiency of the Ti and Zr inoculants by increasing the precipitation of Al3Ti, Al3Zr and Al3(Zr, Ti) particles and the stability of these particles under high temperature conditions, which will result in the finer grains and eutectic phase in weld centre and the higher mechanical properties of the welds. When the amount of Mn is 0.58%(mass fraction), the coarse dendrite grains form in the weld centre.

Key words: high strength aluminum alloy; trace elements; nucleation; equiaxed grain

2519-T87高强铝合金是一种可热处理强化的铝合金,由于其具有较高的强度和良好的抗腐蚀性能,被广泛应用于航空航天材料上[1-3]。目前针对这种铝合金普遍采用电弧焊进行焊接,但由于电弧焊热输入较高,焊后接头强度低,热影响区严重软化,影响其在工业上的应用[4]。为了提高其接头的强度,国内外进行了大量实验研究,诸如添加电磁搅拌,采用脉冲焊接或高能束的焊接工艺,以及设计合适的焊丝[5],其中焊丝成分对接头的性能影响较大。目前针对这种高强铝合金的焊接,国内外普遍采用ER2319焊丝,由于这种焊丝中含有一定量的Ti和Zr,这些元素与Al相互作用形成Al3Ti和Al3Zr颗粒在凝固过程中作为形核点起到促进异质形核的作用,从而细化晶粒。基于此,目前对于焊丝方面的研究均是在ER2319的基础上添加更多的Ti、Zr和Sc来细化焊缝晶粒,对于添加其它微量元素的研究则相对较少[6]。Ce元素在铸造中经常被用来细化晶粒,Cr和Mn元素也经常被用于铝合金中阻碍再结晶形核和生长,但是将这些元素作为添加剂用于焊丝中的研究还没有相关报道。本文作者通过在ER2319焊丝的基础上分别添加少量的Ce、Cr和Mn元素,研究这3种元素与Ti和Zr元素的相互作用机制,以及各自的细化焊缝组织的机理,为2519高强铝合金的焊丝设计提供理论参考。

1 实验

实验采用的材料为2519-T87高强铝合金,实验过程中共采用4组焊丝,其中7焊#丝是在ER2319基础上添加少量Ce元素,8#焊丝是在ER2319焊丝的基础上添加少量的Cr元素,9#焊丝是在美国ER2319焊丝基础上增加了Mn元素的含量。母材和焊丝的成分如表1所列。实验采用平板对接,板材的尺寸为360 mm×220 mm×20 mm,坡口形貌为X型,角度为70?。焊前试板和垫板都用丙酮进行除油污处理,并用钢丝刷除去坡口表面的氧化膜。20 mm厚板材采用正反焊接,正面3道,反面2道,焊接工艺参数为:电流200 A,电压23 V,焊接速度40 cm/min,送丝速度5.6 m/min。焊后在最后一道焊缝上取样,抛磨后采用Keller试剂(0.5%HF+1.5%HCl+2.5%HN03+95.5%H2O)进行侵蚀。采用光学电镜以及扫描电镜观察其微观组织,并用扫描电镜上配套的能谱仪进行成分分析。焊接接头的拉伸实验按照GB2651—89标准在UH-F50A(250 kN)拉伸实验机上进行。

表1 焊丝的主要成分

Table 1 Compositions of base metal and filler metals

2 结果及分析

2.1 焊缝组织

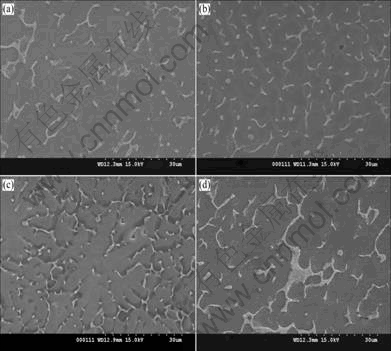

图1所示为几种焊丝焊接接头的显微组织。高强铝合金的焊缝组织以α(Al)为主,在基体晶界上分布着大量α+θ(CuAl2)共晶组织,局部区域还能析出α+θ(CuAl2)+T(CuMn2Al12)三相共晶组织,晶体内部析出θ(CuAl2)等强化相。从图1中可以看出,相对于ER2319焊丝焊接接头的焊缝组织,其它焊丝焊接接头的焊缝组织都得到一定程度的细化,其中8#焊丝焊接接头的焊缝组织最为细小。

图1 不同焊丝焊接接头的显微组织

Fig.1 Microstructures of welds produced by different filler wires: (a) Wire 7; (b) Wire 8; (c) Wire 9; (d) ER2319

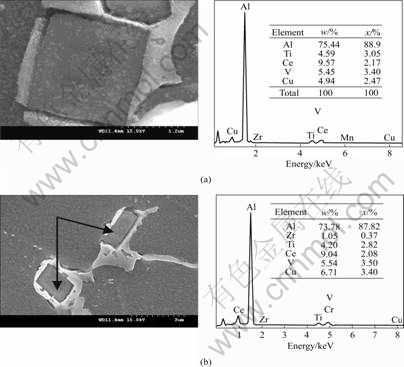

图1(a)所示为7#焊丝焊接接头的焊缝组织,从图中可以看出其呈柱状,且枝晶间的间距比较小。由于7#焊丝中添加了一定量的稀土元素Ce。其它形核剂是作为形核点来细化晶粒,而Ce的细化作用主要是针对二次枝晶。由于Ce的平衡分配系数远小于1,因此容易在晶界上富集,增大了成分过冷区使枝晶分枝生长加剧,从而减少了二次枝晶间距。此外,稀土元素还能降低铝液体形核所需的表面张力,有利于细化晶 粒[7-9]。但是Ce容易与Ti、V和Cu在晶界形成复杂的AlTiVCeCu金属间化合物,如图2(a)所示。这种金属间化合物硬而脆且与基体的结合力比较弱,严重影响了接头的力学性能。此外,Ce与Ti和V形成块状AlTiVCeCu金属间化合物,减少了Ti和V等溶质元素与Al形成Al3Ti和Al3V颗粒的几率,从而减弱了Ti和V元素细化晶粒的作用。另外Zr元素也易于在AlTiVCeCu金属间化合物上偏析,如图2(b)所示,大大降低了Zr元素的细化作用。

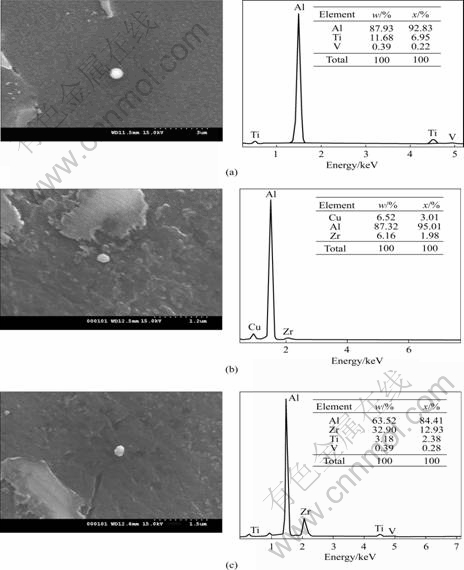

8#焊丝焊接接头的焊缝组织状态主要是等轴晶,且焊缝组织非常细小。由于焊丝中添加了一定量的Cr,Cr与Al的相互作用非常强烈,容易形成稳定性非常好的Al7Cr相,在焊缝凝固过程中Al7Cr相可以作为异质形核点来促进形核,从而细化晶粒。此外Cr与焊缝中其他溶质元素如Fe以及Mn可形成复杂的化合物如Al13(CrFe)2和Al12(CrMn)等,减轻杂质元素的危害,这些颗粒尺寸细小,呈团球状,如图3所示。

图2 AlTiVCeCu金属间化合物的形貌和EDS能谱分析结果

Fig.2 Morphologies and EDS analysis results of AlTiVCeCu phase: (a) AlTiVCeCu; (b) AlTiVZrCeCu

图3 8#焊丝焊接接头中的Al7(CrFe)颗粒SEM像和EDS能谱分析结果

Fig.3 SEM image (a) of Al7(CrFe) particles in weld produced by wire 8 and its EDS analysis results (b)

Cr的异质形核作用还在于其对Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒析出的影响。很多研究证实Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒是很好的非均质形核点,能够有效 促进细小等轴晶的形成[6, 10-11]。平衡态的Al3Ti和Al3Zr均为四方结构,分别属于DO22和DO23结构,其中Al3Ti的晶格常数a=0.3875 nm,c=3.387 nm;Al3Zr的晶格常数a=0.4012 nm,c=1.732 nm;而Al属于面心立方结构,其晶格常数a=0.405 nm。Al3Ti、Al3Zr与Al的错配度都低于10%,是非常有效的形核核心。由于Al3(Tix, Zr1-x)颗粒的界面能要小于Al3Zr颗粒,因此是比Al3Zr颗粒更加有效的异质形核点[12]。Cr对这些颗粒的作用首先表现在它们能改善液态铝和固态Al3Ti、Al3Zr、Al3(Ti, Zr)之间的界面性能,降低其表面张力,能够有效地改善这些质点非均质形核效果,并且能够抑制它们的长大[13]。而且固溶在铝液中的Cr由于d电子层未充满,与Al有较强的亲和力,易于进入因能量起伏和成分起伏形成的原子簇团,含有Cr的原子簇团非常稳定而且易于长大,它们可以作为Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒存在的形核基底,从而显著增加熔池中异质形核点的数目。当这些原子簇团的尺寸长大到一定值后还可以作为铝液的形核点促进形核[13]。扫描电镜观察的结果也证实了这一点,在8#焊丝的焊缝中比较容易观察到Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒的存在,如图4所示;而在7#焊丝和ER2319焊丝中很少能发现这些颗粒。由于熔池中存在大量的Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒,有足够的异质形核点促进柱状晶向等轴晶发生转变,因此8#焊丝焊缝呈等轴晶态。通过成分分析发现,这些颗粒物内都含有少量的V。V主要是通过替代其中的Zr和Ti原子进入这些颗粒内,V的加入能够减少其与Al在c轴上的错配度,并且能提高这些颗粒物在高温下的稳定性[14],降低其在高温条件下熔化的可能性,从而提升异质形核的效果。

9#焊丝的Mn含量比较高,Mn与Cr有相似的作用,对细化晶粒有一定的帮助。但当Mn含量较高时,易显著增加固溶体的过饱和度,降低结晶前沿液相中的成分过冷,使枝晶向液相中继续生长。因此当Mn含量达到0.58%时,焊缝中心反而会出现粗大的枝晶,如图1(c)所示。

图5所示为不同焊丝焊接接头的组织形貌。从图中可以看出,4种焊丝接头熔合线附近均存在一个等轴晶区,其中8#焊丝的熔合线附近等轴晶区的宽度为105 μm,9#焊丝的等轴晶区的宽度为100 μm,7#焊丝以及ER2319焊丝等轴晶区的宽度分别为40 μm和50 μm。关于这种等轴晶区的形成机理,GUTIERREZ 等[15]认为该区形成不是再结晶的结果,而是一个形核和长大的过程,主要是母材中的Al3Zr和Al3Ti颗粒在凝固过程中提供了大量的异质形核点促进形核造成的。REDDY等[16]利用TEM在这个区域观察到了Al3Zr的存在,并且研究发现这个区域的形成温度在630~640 ℃之间。LIN等[17]研究发现出除了母材外焊丝成分对熔合线附近等轴晶区的形成也有较大影响,熔池中的异质形核颗粒可以通过熔池的强对流而被卷入到熔合线附近促进等轴晶区的形成。4种焊丝熔合线附近等轴晶区宽度的差别,可以认为是熔池中异质形核点数量的差别造成的,由于Cr和Mn的加入可以减少液态金属与固相的表面张力,从而增加异质形核点的数量,改善其异质形核效果,相对来说其焊缝中的异质形核点颗粒更多[18],更加易于卷入到熔合线附近的未混合区,促进等轴晶区的形成,因此在熔合线附近能形成较宽的等轴晶区。

图4 8#焊丝焊接接头中的异质形核点SEM像及其EDS能谱分析结果

Fig.4 SEM images of Al3Ti, Al3Zr and Al3(Ti, Zr) particles and EDS analysis results in weld produced by wire 8: (a)Al3Ti; (b)Al3Zr; (c)Al3(Tix, Zr1-x)

图5 不同焊丝焊接接头的组织形貌

Fig.5 Morphologies of weld joints with produced by different filler wires: (a) Wire 7; (b) Wire 8; (c) Wire 9; (d) ER2319

2.2 共晶组织形态

图6所示为几种焊丝所得焊缝中共晶相的形貌。

图6 几种焊丝焊缝中的共晶相形貌

Fig.6 Morphologies of eutectic phase in welds produced by different filler wires: (a) Wire 7; (b) Wire 8; (c) Wire 9; (d) ER2319

从图中可以看出ER2319焊丝所对应的焊缝中晶界上共晶相数量多,宽度大,且呈网络状分布,而其他几种焊丝焊缝中的共晶相数量相对比较少,宽度小,且呈短棒状不连续分布。其中8#焊丝焊缝中晶界共晶相尺寸最小,很多接近颗粒状分布。Ce对共晶相的细化作用,主要是因为稀土元素的活性作用以及晶界面积的增加[7-9],Cr和Mn对晶界共晶相的细化作用主要是因为晶界面积的增加。由于晶界共晶相脆性比较大,很容易开裂,而且随着晶界共晶相宽度的增加,其开裂所需的拉力随之减少,因此ER2319焊丝所获接头的力学性能比较差。而颗粒状的共晶相开裂比较困难,对位错运动有一定的阻碍作用,能起到一定的弥散强化作用[19]。

2.3 焊接接头的力学性能

表2所列为几种焊丝焊接接头的力学性能。从表中可以看出,3种自行研制的焊丝接头的抗拉强度均高于美国ER2319焊丝接头的抗拉强度,RmW/RmB也都达到了0.6以上,冲击韧性以及塑性也与ER2319相当,其中8#焊丝焊接接头的强度最高。3种焊丝相对于ER2319焊丝接头性能有较大程度的提升,一部分原因是3种焊丝所获焊缝组织更为细小,焊缝中共晶相的数量少且不呈连续网络状分布,并且微量元素Cr、Ti、Mn、Ce和Zr对焊缝都有较好的固溶强化作用,此外,稀土元素Ce、Cr和Mn元素都能与Al形成化合物起到一定的析出强化作用。

表2 几种焊丝焊接接头的力学性能

Table 2 Mechanical properties of weld joints produced by different filler wires

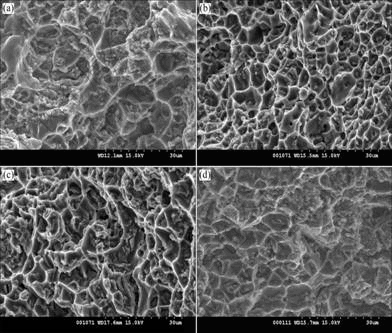

图7所示为不同焊丝焊接接头拉伸断口的形貌。

图7 不同焊丝焊缝断口的形貌

Fig.7 Fractograph of tensile specimens with different filler wires: (a) Wire 7; (b) Wire 8; (c) Wire 9; (d) ER2319

从图中可以看出,4种型号焊丝的接头拉伸断口都是韧窝型断口。其中7#焊丝焊接接头断口中的韧窝尺寸较大,局部区域还能观察到二次裂纹的存在。由于晶界上易于形成粗大的复杂AlTiVCeCu金属间化合物,降低了晶界和基体的结合力,易于发生开裂,此外粗大的AlTiVCeCu金属间化合物可以作为韧窝的形核点,从而使韧窝的尺寸增大。8#焊丝焊接接头断口中的韧窝非常细小,且分布均匀,韧窝底部的共晶相数量也比较少。9#焊丝由于其Mn含量比较高,容易在晶界上形成较多的共晶相,因此焊接接头断口中的韧窝底部的共晶相数量比较多,图7(c)也能证实这一点。

3 结论

1) Ce能细化焊缝二次枝晶间距,但由于Ce与Ti、V和Zr形成比较复杂的金属间化合物,降低了Ti和Zr的异质形核作用,使焊缝组织呈柱状。

2) Cr和Mn元素均能够稳定Al3Ti、Al3Zr和Al3(Ti, Zr)颗粒,改善其异质形核条件,使焊缝组织呈等轴晶态,且在熔合线附近易形成较宽的等轴晶区。但当Mn的含量达到0.58%时,焊缝中心易出现粗大的 枝晶。

3) 添加了微量元素的焊丝焊缝晶界共晶相数量有所少,且呈不连续分布,其中添加了Cr元素的焊缝晶界共晶相数量最少,且接近颗粒状分布。

4) 添加了微量元素的焊丝的接头抗拉强度均高于ER2319焊丝的,RmW/RmB均达到0.6以上,冲击韧性以及塑性也与ER2319的相当,其中含有Cr元素的焊接接头强度最高。

REFERENCES

[1] KRAMER L S, BLAIR T P, BLOUGH S D. Stress-corrosion cracking susceptibility of various product forms of aluminum alloy 2519[J]. Journal of Materials Engineering and Performance, 2002, 11(6): 645-650.

[2] CARTER H B, ASHOK S. Transient crack growth behavior in aluminum alloys C415-T8 and 2519-T87[J]. Engineering Fracture Mechanics, 1999, 62(1): 1-22.

[3] FISHER J, JAMES J. Aluminum alloy 2519 in military vehicles [J]. Advanced Material and Processes, 2002, 160(9): 43-46.

[4] DEVINCENT S M, DEVLETIAN J H, GEDEON S A. Weld properties of the newly developed 2519-T87 aluminum armor alloy[J]. Welding Journal, 1988, 67(7): 33-43.

[5] JANAKI R, MITRA T K, OLSON D L. Use of inoculants to refine weld solidification structure and improve weldability in type 2090 Al-Li alloy[J]. Mater Sci Eng A, 2000, 276(1/2): 48.

[6] 国旭明, 杨成刚, 钱百年. 孕育剂Ti, Zr对2219 Al-Cu合金焊缝组织及性能的影响[J]. 金属学报, 2005, 41(4): 397-401.

GUO Xu-ming, YANG Cheng-gang, QIAN Bai-nian. Effects of inoculants Ti and Zr on the microstructures and properties of 2219 Al-Cu alloy welds[J]. Acta Metallurgica Sinica, 2005, 41(4): 397-401.

[7] 吴国华, 马春江, 王叶双. 稀土对B319铝合金组织和性能的影响[J]. 金属学报, 2002, 38(7): 703-708.

WU Guo-hua, MA Chun-jiang, WANG Ye-shuang. Effect of RE on the structure and mechanical properties of B319 aluminum alloy[J]. Acta Metallurgica Sinica, 2002, 38(2): 703-708.

[8] 肖代红, 王健农, 丁冬雁. 稀土 Ce 对铸态 AlCuMgAg 合金耐热性能的影响[J]. 特种铸造及有色合金, 2004, 24(4): 20-22.

XIAO Dai-hong, WANG Jian-nong, DING Dong-yan. Effects of rare earth Ce on the heat-resisting properties of cast AlCuMgAg alloy[J]. Special Casting & Nonferrous alloys, 2004, 24(4): 20-22.

[9] 仲志国, 左秀荣, 孙海斌, 王明星, 翁永刚, 常德旭. 细化及变质方法对A356铝合金微观组织的影响[J]. 铸造技术, 2006, 27(1): 49-51.

ZHONG Zhi-guo, ZUO Xiu-rong, SUN Hai-bin, WANG Ming-xing, WENG Yong-gang, CHANG De-xu. Influence of refining and modification manners on microstructure of A356 aluminum alloys[J]. Foundry Technology, 2006, 27(1): 49-51.

[10] JANKI RAN G D, MITRA T K, SHANKAR V. Microstructural refinement through inoculation of type 7020 Al-Zn-Mg alloy welds and its effects on hot cracking and tensile properties[J]. Journal of Materials Processing Technology, 2003, 142(1): 174-181.

[11] SKATAYAMA. Solidification phenomena of weld metals (1st report). Characteristic solidification morphologies, micro- structures and solidification theory[J]. Welding International, 2000, 14(12): 25-37.

[12] NAYAK S S, PABI S K, MURTY B S. High strength nanocrystalline L12-Al3(Ti, Zr) intermetallic synthesized by mechanical alloying[J]. Intermetallics, 2007, 15(1): 26-33.

[13] 贺永东, 张新明. 微量Cr、Mn、Ti、Zr细化7A55铝合金铸锭组织的效果与机理[J]. 中国有色金属学报, 2005, 15(10): 1594-1601.

HE Yong-dong, ZHANG Xin-ming. Refinement mechanism of trace Cr, Mn, Ti and Zr as cast 7A55 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1594-1601.

[14] YING J K, OHASHI T. Precipitation structures and mechanical properties of Al-Li-Zr alloy containing V[J]. Scripta Materialia, 1999, 41(2): 134-141.

[15] GUTIERREZ A, LIPPOLD J C. A proposed mechanism for equiaxed grain formation along the fusion boundary in aluminum-copper-lithium alloy[J]. Welding Journal, 1998, 77(3): 123-132.

[16] REDDY G M, GOKHALE A A, PRAFAD K S. Chill zone formation in Al-Li alloy welds[J]. Science and Technology of welding and Joining, 1998, 3(4): 208-212.

[17] LIN D C, WANG G X, SRIVATSAN T S. A mechanism for the formation of equiaxed grains in welds of aluminum-lithium alloy 2090[J]. Mater Sci Eng A, 2003, 351: 304-309.

[18] MURTY B S, KORI S A, CHAKRABORTY M. Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying[J]. International Materials Reviews, 2002, 47(1): 3-29.

[19] 国旭明, 杨成刚, 钱百年. 高强Al-Cu合金脉冲MIG焊工艺[J]. 焊接学报, 2004, 25(4): 5-9.

GUO Xu-ming, YANG Chen-gang, QIAN Bai-nian. Pulse MIG welding process of high strength Al-Cu alloy[J]. Transaction of the China Welding Institute, 2004, 25(4): 5-9.

基金项目:国家高技术研究发展计划资助项目(2002AA305402)

收稿日期:2007-10-08;修订日期:2008-01-22

通讯作者:许良红,博士;电话:010-62182565-418;E-mail: xlh_smile@yahoo.com.cn

(编辑 何学锋)