文章编号:1004-0609(2012)07-2103-06

二段脱铜液还原结晶法脱砷新工艺

郑雅杰,崔 涛,彭映林

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:对铜电解液脱砷方法进行研究,提出以二段脱铜液为原料,采用SO2还原结晶法脱砷新工艺。在二段脱铜液中通入SO2,将其中的As(Ⅴ)还原成As(Ⅲ),还原后的溶液通过蒸发结晶析出As2O3,达到二段脱铜液脱砷的目的。结果表明:当As(Ⅴ)浓度为12.41 g/L、H2SO4浓度为253.00 g/L、反应温度为60 ℃时,向二段脱铜液中通入SO2 90 min后静置90 min,二段脱铜液中As(Ⅴ)的还原率达到94.54%。还原后的溶液进行蒸发结晶,当蒸发前与结晶后的体积比(V0:V1)为3.5时,砷的脱除率达到91.33%,结晶产物为As2O3。与传统脱砷工艺相比,新工艺具有操作简单、成本低廉及砷的脱除效果明显等优势。

关键词:二段脱铜液;砷;还原;结晶

中图分类号:TF803.25 文献标志码:A

New process of arsenic removal from second stage decopperizing electrolyte by reduction and crystallization

ZHENG Ya-jie, CUI Tao, PENG Ying-lin

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The process of arsenic removal from copper electrolyte was studied. A new process for the removal of arsenic from the second stage decopperizing electrolyte by reducing with SO2, and the following crystallization was proposed. As (Ⅴ) in the second stage decopperizing electrolyte was reduced to As (Ⅲ) with SO2. As2O3 was produced from the reduced solution by the evaporation and crystallization. The purpose of arsenic removal from the second stage decopperizing electrolyte was achieved in the experimental. The results show that the reduction rate of As(Ⅴ) reaches 94.54% under the conditions of As(Ⅴ) concentration of 12.41 g/L, H2SO4 concentration of 253.00 g/L, reaction temperature of 60 ℃, the aeration time of SO2 of 90 min and standing time of 90 min. The removal rate of arsenic is 91.33% when the volume ratio of the reduced solution to the crystallized solution is 3.5. The crystallized products are As2O3. Compared with the conventional process of the arsenic removal from copper electrolyte, the new process has the advantages of simple operation, low cost and high removal rate of arsenic.

Key words: second stage decopperizing electrolyte; arsenic; reduction; crystallization

铜电解过程中,阳极铜所含的有害杂质砷除 20%~40%进入阳极泥外,其余部分则进入电解液。随着电解作业的进行,电解液中的砷与锑、铋、铁和镍等杂质逐渐积累,它们不仅会在阴极上沉积,而且会形成漂浮阳极泥,影响阴极铜质量。因此,必须对电解液进行净化,使有害杂质砷等降至允许浓度以下,以确保阴极铜的质量[1]。在传统除砷方法电积法[2]中,砷与铜一起在阴极上形成黑铜粉而析出,但该方法能耗高、易产生剧毒气体砷化氢,且造成砷在铜冶炼体系中的闭路循环。为此,许多新方法如萃取法[3-4]、离子交换法[5]、吸附法[6-7]和化学沉淀法[8-10]等被提出,但这些方法因为其本身的缺点,难以应用于大规模的工业生产。

铜电解液中的砷主要以As(Ⅴ)的形态存在,其在溶液中的溶解度很大,而As(Ⅲ)的溶解度则相对较小,LINDROOS和VIRTANEN[11]提出了一种通过SO2还原法使高酸铜电解液中的As(Ⅴ)还原而生成As2O3的方法,此法对于铜电解液中砷的脱除效果很好,但其生产条件较为苛刻,能耗和对设备的要求都较高。陈永康[12]对铜电解液还原净化脱砷工艺进行了研究,并提出了以KI为催化剂使用SO2还原铜电解液中的砷,该方法可以在较为温和的条件下脱除铜电解液中的砷等多种杂质,不足之处在于在铜电解液中引入了卤素离子,对电解液形成新的污染。本文作者在研究SO2还原As(Ⅴ)反应原理以及砷在酸性溶液中溶解规律的基础上,提出以铜电解液净化过程中产生的二段脱铜液为原料、通入SO2气体将溶液中的As(Ⅴ)还原成As(Ⅲ),再通过蒸发结晶脱除砷的方法,使得溶液中砷的脱除率达到90%以上,为铜电解体系中有害元素砷的去除提供了一种简单而有效的新方法。

1 实验

1.1 实验步骤

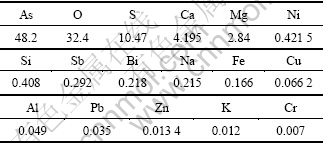

取一定体积的二段脱铜液置于三颈瓶中,二段脱铜液成分如表1所列。启动搅拌,在电热套中加热到一定温度后通入SO2气体,通气结束后将三颈瓶密闭并保温一定时间使溶液中的As(Ⅴ)充分还原。还原后的溶液,在烧杯中加热并搅拌蒸发掉一定量的水分后,在15 ℃下进行冷却结晶,结晶后的溶液过滤得到As2O3晶体和净化后溶液。根据上述实验步骤,其工艺流程如图1所示。

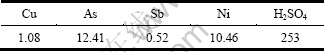

表1 二段脱铜液成分

Table 1 Composition of second stage decopperizing electrolyte (g·L-1)

图1 还原结晶法脱砷工艺流程图

Fig. 1 Flow sheet of arsenic removal by reduction and crystallization method

1.2 分析与检测

实验采用硫酸铈-溴酸钾滴定法分析As(Ⅲ)浓度;采用电感耦合等离子光谱仪(Intrepid II XSP)分析Cu、As、Sb、Bi和Ni等的浓度;采用X荧光分析(XRF)仪分析结晶产物成分;采用X衍射(XRD)仪分析结晶产物物相。

采用式(1)计算As(Ⅴ)的还原率(ω):

×100% (1)

×100% (1)

式中:ρ0表示溶液总砷浓度(g/L);ρ1和ρ2分别表示还原前后溶液中As(Ⅲ)的浓度(g/L);V0和V1分别表示溶液还原前后的体积(L)。

2 结果与讨论

2.1 静置时间对As(Ⅴ)还原率的影响

取二段脱铜液300 mL,当反应温度为60 ℃、通气时间为30 min、SO2流量为200 mL/min时,通气结束后将三颈瓶在电热套中保温静置,静置时间对As(Ⅴ)还原率的影响如图2所示。

图2 静置时间对As(Ⅴ)还原率的影响

Fig. 2 Influence of standing time on reduction rate of As (Ⅴ)

由图2可知:通入SO2气体后,随着静置时间的延长,As(Ⅴ)的还原率增加。当静置时间从0延长至180 min时,As(Ⅴ)的还原率从50.79%增加至 94.54%。通入SO2气体后,增加反应时间有利于反应的充分进行,当静置时间达到90 min后;继续延长静置时间As(Ⅴ)的还原率无明显变化。因此,适宜的静置时间选取90 min,此时As(Ⅴ)的还原率为89.65%。

2.2 通气时间对As(Ⅴ)还原率的影响

其他条件不变,当静置反应时间为90 min时,通气时间对As(Ⅴ)还原率的影响如图3所示。

图3 通气时间对As(Ⅴ)还原率的影响

Fig. 3 Influence of aeration time on reduction rate of As (Ⅴ)

由图3可知: 随着通气时间的延长,As(Ⅴ)的还原率增加;当通气时间由10 min延长至90 min时,As(Ⅴ)的还原率从75.39%增加至94.54%。随着通气 时间的延长,溶液中溶解的SO2的量增加,同时通气时间的延长也增加了SO2与As(Ⅴ)的反应时间,使反应进行得更彻底。当通气时间延长到90 min时,As(Ⅴ)的还原率高达94.54%;继续延长通气时间,As(Ⅴ)的还原率增加不明显。因此,适宜的通气时间为90 min,其As(Ⅴ)的还原率为94.54%。

2.3 SO2流量对As(Ⅴ)还原率的影响

其他条件不变,当通气时间为90 min时,SO2流量对As(Ⅴ)还原率的影响如图4所示。

由图4可知:SO2流量的变化对溶液中As(Ⅴ) 还原率没有显著的影响。当气流量从60 mL/min增加至300 mL/min时,As(Ⅴ)还原率基本保持在95%左 右。LI和LAWSON[13]及KRISSMANN等[14]的研究表明,SO2还原As(Ⅴ)的过程分两步进行:第一步是 SO2气体的溶解,第二步是As(Ⅴ)与SO2的氧化还原反应。当SO2流量较大时,第二步为速度控制步骤。但是气流量较大,SO2不能及时溶解,大量的SO2气体逸出会恶化实验条件并造成浪费,所以,在实验时宜采用较小的气流量并在通气结束后静置一段时间 使溶液中的SO2与As(Ⅴ)充分反应。适宜的SO2气体流量选择为60 mL/min,此时As(Ⅴ)的还原率为94.85%。

图4 SO2气流量对As(Ⅴ)还原率的影响

Fig. 4 Influence of flow rate of SO2 on reduction rate of As(Ⅴ)

2.4 反应温度对As(Ⅴ)还原率的影响

其他条件不变,当SO2流量为60 mL/min时,反应温度对As(Ⅴ)还原率的影响如图5所示。

图5 反应温度对As(Ⅴ)还原率的影响

Fig. 5 Influence of reaction temperature on reduction rate of As(Ⅴ)

由图5可知:随着反应温度的升高,As(Ⅴ)的还原率升高,并在一定温度范围内基本保持不变;再继续升高温度,As(Ⅴ)的还原率有所下降。当初始硫酸浓度为0.1 mol/L时,SO2在溶液中达到溶解平衡时的浓度如表2[13]所列。

由表2中数据可知,SO2的溶解度随着温度的升高而降低。升高温度有利于还原反应的进行,所以,As(Ⅴ)的还原率随着温度的升高而增大;当温度在45~75 ℃范围内变化时,反应速度增加,但SO2的溶解度降低,所以,As(Ⅴ)的还原率变化不大;当温度继续升高时,SO2的溶解度继续降低,溶液在相同通气时间下溶解的SO2减少,从而导致As(Ⅴ)的还原率降低。反应温度过低或过高都会使As(Ⅴ)还原率降低,适宜的反应温度应选择在45~75 ℃范围内,本实验以工厂中二段脱铜液的温度来进行实验选为60 ℃,此 时As(Ⅴ)的还原率可达到94.54%。

表2 SO2在硫酸溶液中的溶解度(硫酸初始浓度为0.1 mol/L)[13]

Table 2 Solubility of SO2 in sulfuric acid (Initial acid concentration 0.1 mol/L)[13]

2.5 硫酸浓度对As(Ⅴ)还原率的影响

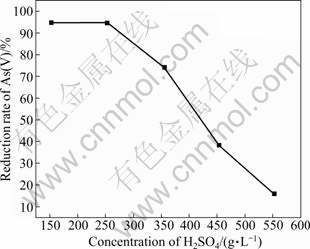

其他条件不变,当反应温度为60 ℃时,硫酸溶液浓度对As(Ⅴ)还原率的影响如图6所示。

图6 硫酸浓度对As(Ⅴ)还原率的影响

Fig. 6 Influence of sulfuric acid concentration on reduction rate of As(Ⅴ)

由图6可知:随着硫酸浓度的升高,As(Ⅴ)还原率降低。研究表明,在强酸性的溶液中SO2与As(Ⅴ)发生反应时,主要参与反应的形态为H2SO3和 ,其反应式如下:

,其反应式如下:

H3AsO4+H2SO3=H2SO4+HAsO2+H2O (2)

H3AsO4+ =

= +HAsO2+H2O (3)

+HAsO2+H2O (3)

从式(2)和(3)可以看出,溶液中参与反应的As(Ⅴ)是H3AsO4,当硫酸浓度过高时,H3AsO4与溶液中的H+发生离子化反应[15]:

H3AsO4(aq)+H+(aq)

(4)

(4)

生成 ,

, 的活泼性比H3AsO4低很多,抑制了反应的进行。当硫酸浓度从153 g/L升高到 553 g/L时,As(Ⅴ)还原率从92.09%降低至15.88%。实验所用电积脱铜液的硫酸浓度为253 g/L,在此酸度下采用SO2还原,As(Ⅴ)的还原率可达94.54%。

的活泼性比H3AsO4低很多,抑制了反应的进行。当硫酸浓度从153 g/L升高到 553 g/L时,As(Ⅴ)还原率从92.09%降低至15.88%。实验所用电积脱铜液的硫酸浓度为253 g/L,在此酸度下采用SO2还原,As(Ⅴ)的还原率可达94.54%。

从单因素实验结果可以得出SO2还原二段电积脱铜液中As(Ⅴ)的适宜条件如下:每300 mL溶液在气流量为60 mL/min时需通气90 min,通气结束后静置90 min,反应温度为60 ℃,硫酸溶液浓度为253 g/L,在此条件下,溶液中的As(Ⅴ)还原率可达94.54%。

2.6 还原后二段脱铜液中砷的脱除

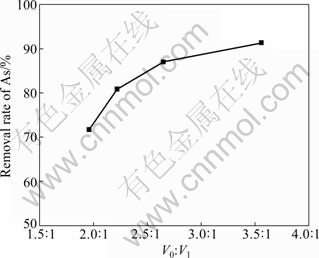

取1 L还原后的二段脱铜液置于玻璃烧杯中进行蒸发,蒸发一定体积后的溶液在15 ℃下进行冷却结晶。蒸发前体积与结晶后体积比(V0:V1)对As脱除率 的影响如图7所示。

图7 V0:V1对As脱除率的影响

Fig. 7 Influence of V0:V1 on removal rate of As

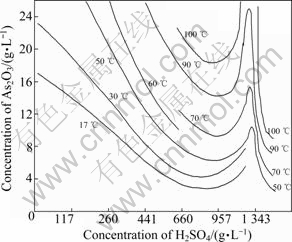

由图7可知:As的脱除率随着V0:V1的增大而增加,当V0:V1达到3.5时,溶液中硫酸浓度达到900 g/L,结晶后As的脱除率达到91.33%。图8[16]所示为As2O3在不同温度和不同硫酸溶液浓度下的溶解度曲线。从图8可以看出:As2O3在硫酸溶液中的溶解度随硫酸浓度的变化比较复杂,在硫酸浓度为900 g/L左右时达到一个较低值,在此条件下进行冷却结晶可以达到较好的脱砷效果,实验结果与图8所示结果一致。因此,在蒸发结晶脱砷时,适宜的V0:V1选择为3.5:1。

图8 不同温度下As2O3在硫酸溶液中溶解度曲线[16]

Fig. 8 Solubility curves of As2O3 in sulfuric acid solution at various temperatures[16]

根据上述条件,取3 L二段脱铜液进行实验室放大实验,采用SO2还原后蒸发浓缩,15 ℃时冷却结 晶,过滤得滤液0.86 L。净化前后溶液成分如表3所列。对放大实验所得结晶产物进行XRF和XRD检 测,检测结果分别如表4和图9所示。

表3 二段脱铜液净化前后成分

Table 3 Compositions of second stage decopperizing electrolyte before and after purification

从表3的结果计算可知:放大实验中二段脱铜液中As的脱除率为91.15%,净化后的溶液中Cu、As

和Sb等含量较低,达到了很好的脱砷效果。净化后溶液中Ni的浓度较高,经过冷冻结晶回收硫酸镍后,即可作为硫酸补充到铜电解液中去。

从表4和图9的检测结果分析得出:结晶产物的主要物相为As2O3,其次为CaSO4和少量其他物质,Ni、Cu和Sb的含量很低。

表4 结晶产物成分

Table 4 Chemical composition of crystallized product (mass fraction, %)

图9 结晶产物的XRD谱

Fig. 9 XRD pattern of crystallized product

3 结论

1) 采用SO2还原二段脱铜液,As(Ⅴ)的还原率随着通气时间和静置时间的延长而升高,随着反应温度和硫酸浓度的增加而降低。

2) 采用SO2还原二段脱铜液中的As(Ⅴ),二段脱铜液中As(Ⅴ)浓度为12.41 g/L、硫酸浓度为253.00 g/L,在60 ℃时通入SO2气体90 min后静置反应90 min,As(Ⅴ)的还原率达到94.54%。

3) 还原后的二段脱铜液加热蒸发后在15 ℃下进行冷却结晶,当蒸发前体积与结晶后体积比(V0:V1)为3.5:1时,结晶后砷的脱除率达91.33%,结晶产物主要为As2O3。

REFERENCES

[1] 朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003: 558-572.

ZHU Zu-zhe, HE Jia-qi. Modern copper metallurgy [M]. Beijing: Science Press, 2003: 558-572.

[2] ALAM M S, TANAKA M, KOYAMA K. Electrolyte purification in energy-saving monovalent copper electrowinning processes [J]. Hydrometallurgy, 2007, 87(1/2): 36-44.

[3] GUPTA B, BEGUM Z I. Separation and removal of arsenic from metallurgical solutions using bis-(2, 4, 4-trimethylpentyl) dithiophosphinic acid as extractant [J]. Separation and Purification Technology, 2008,63: 77-85.

[4] REDDY B R, PARK K H, MOHAPATRA D. Process development for the separation and recovery of copper from sulphate leach liquors of synthetic Cu-Ni-Co-Fe matte using LIX 84 and LIX 973 N [J]. Hydrometallurgy,2007, 87(1/2): 51-57.

[5] BACIOCCHI R, CHIAVOLA A, GAVASCI R. Ion exchange equilibria of arsenic in the presence of high sulphate and nitrate concentrations [J]. Water Science and Technology, 2005, 5(5): 67-74.

[6] AMIN M N, KANECO S, KITACAWA T, BEGVM A, KATSUMATA H, SUZUKI T. Removal of arsenic in aqueous solutions by adsorption onto waste rice husk [J]. Industrial and Engineering Chemistry Research, 2006, 45(24): 8105-8110.

[7] 王学文, 陈启元, 龙子平, 苏中府, 尹周润, 张平民. Sb在铜电解液净化中的应用[J]. 中国有色金属学报, 2002, 12(6): 1277-1280.

WANG Xue-wen, CHEN Qi-yuan, LONG Zi-ping, SU Zhong-fu, YIN Zhou-lan, ZHANG Ping-min. Application of antimony in purification of copper electrolyte [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1277-1280.

[8] 王学文, 肖炳瑞, 张 帆. 铜电解液碳酸钡脱铋新工艺[J]. 中国有色金属学报, 2006, 16(7): 1295-1299.

WANG Xue-wen, XIAO Bing-rui, ZHANG Fan. New process of bismuth removal from copper electrolyte with barium carbonates [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1295-1299.

[9] WANG Xue-wen, CHEN Qi-yuan, YIN Zhou-lan, WANG Ming-yu, TANG Fang. The role of arsenic in homogeneous precipitation of As, Sb, and Bi impurities in copper electrolyte [J]. Hydrometallurgy, 2011, 108(3/4): 199-204.

[10] XIAO Fa-xin, ZHENG Ya-jie, WANG Yong, XU Wei, LI Chun-hua, JIAN Hong-sheng. Novel technology of purification of copper electrolyte [J]. Transaction of Nonferrous Metals Society of China, 2007, 17(5): 1069-1074.

[11] LINDROOS L, VIRTANEN H. Method for the removal of arsenic from sulfuric acid solution: USA, 6495024 B1 [P]. 2002-12-07.

[12] 陈永康. 铜电解液还原净化脱砷工艺研究[J]. 有色金属: 冶炼部分, 1998(1): 8-12.

CHEN Yong-kang. Research of the process to removal arsenic from copper electrolyte by reduction [J]. Nonferrous Metals: Extractive Metallurgy, 1998(1): 8-12.

[13] LI Nan, LAWSON F. Kinetics of heterogeneous reduction of arsenic (V) to arsenic (III) with sulfur dioxide [J]. Hydrometallurgy, 1989, 22(3): 339-351.

[14] KRISSMANN J, SIDDIQI M A, LUCAS K. Thermodynamics of SO2 absorption in aqueous solutions [J]. Chemical Engineering and Technology, 1998, 21(8): 641-644.

[15] PALMER B R, NAMI F, FUERSTENAU M C. Reduction of arsenic acid with aqueous sulfur dioxide [J]. Metallurgical and Materials Transactions B, 1976, 7(3): 385-390.

[16] DALEWSKI F. Removing arsenic from copper smelter gases [J]. Journal of the Minerals Metals and Materials Society, 1999, 51(9): 24-26.

(编辑 陈卫萍)

基金项目:广东省教育部产学研重大项目(2009B090200053)

收稿日期:2011-06-11;修订日期:2011-10-25

通信作者:郑雅杰,教授,博士;电话:0731-88836285;E-mail: zzyyjj01@yahoo.com.cn