文章编号: 1004-0609(2005)08-1253-09

速度等高线法优化喷射成形棒坯的形状控制参数

霍 光1, 2, 邓德国2, 谢 明2, 郑福前2

(1. 昆明理工大学 材料与冶金工程学院, 昆明 650093;2. 昆明贵金属研究所, 昆明 650221)

摘 要: 提出并建立了喷射成形棒坯的沉积速度等高线模型, 利用计算机数值模拟技术计算了喷射成形空间质量流率分布, 找到了沉积器的最佳位置zm与最佳回缩速度v的关系, 分析了不同空间位置对沉积坯端面的影响。 采用二维坐标跟踪计算了沉积坯的形貌, 计算的结果与实际喷射成形铝硅合金棒坯进行了比较, 实验结果与预测得到了较好的吻合。

关键词: 等高线模型; 喷射成形; 棒坯; 数值模拟; 喷射质量流率 中图分类号: TF124.39; TB115

文献标识码: A

Optimization of spray-forming rod condition by contour line

HUO Guang1, 2, DENG De-guo2, XIE Ming2, ZHENG Fu-qian2

(1. School of Materials and Metallurgical Engineering,

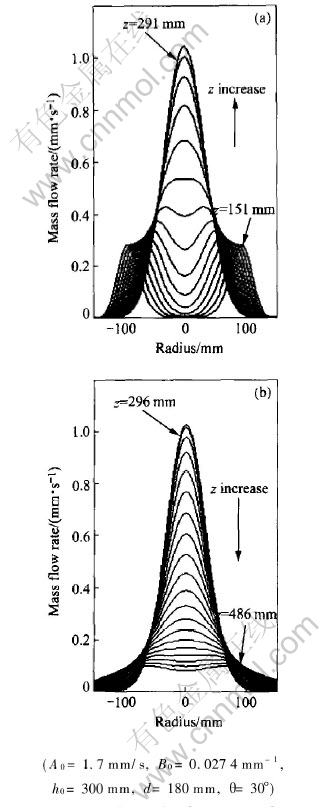

Kunming University of Science and Technology, Kunming 650093, China;

2 Kunming Institute of Precious Metals, Kunming 650221, China)

Abstract: A contour line model was presented for finding the relation between the substrate position (zm) and withdrawal velocity. The droplet flow rate in space during spray forming was analyzed by numerical calculation.The relation between optimum position (zm) and withdrawal velocity was obtain by the contour line model. The influence of substrate position to the rod surface shape were analyzed. A two dimensional model was formulated to calculate the shape of the rod through tracing surface coordinates of the rod. The calculated surface profiles were compared with those of spray-formed Al-Si alloy rods prepared on a pilot scale. The calculated results for the surface profiles were in agreement with those of the spray-formed rods.

Key words: contour line model; spray forming; rod; numerical calculation; spray mass flow rate

雾化喷嘴的结构和运动形式在喷射成形过程中起着重要的作用, 它影响着雾化液滴的质量流率分布、 尺寸分布、 热状态、 沉积坯组织特征等。 根据喷嘴运动方式, 喷射成形工艺可以采用喷嘴做扫描运动[1-4]和静止[5-21]两种类型。 沉积坯的模拟形状可分为棒坯、 管坯、 板坯、 环状坯等形状, 其中以棒坯形状研究的报道最多[1-20]。

国内外众多的研究者对采用静止型喷嘴沉积的棒状坯和管状坯进行了大量研究 [5-21]。 这些研究基本上采用两种方法: 一种是采用质量平均法, 即将同一时刻的质量流率在圆周上进行加和平均后的沉积质量, 作为该圆周上所有点旋转一周后的平均生长速度。 该方法计算得到的二维轮廓在沉积器旋转角速度较大的情况下是准确的(ω≥90°/s)[10], 计算中没有考虑初始相位不同对沉积坯形貌的影响。 但通过该方法可以近似计算在空间不同位置的沉积速率分布[5]。 另一种方法是坐标跟踪法[11, 12], 即对不同点计算其不同时刻的位置坐标, 得到沉积坯轮廓。 采用该方法可以计算沉积坯实时轮廓的二维剖面和三维轮廓, 分析不同初始相位对沉积坯形貌的影响[6]。 该方法的计算量要远大于前一种方法。

由于沉积棒坯的形貌是在沉积器的回缩运动与旋转运动的共同作用下形成的, 沉积坯的沉积速度、 沉积位置、 沉积坯形貌三者关系的定量描述就比较困难。 所以在研究喷射成形工艺中的几何参数对沉积坯形貌影响时, 研究人员大多从偏心距、 初始沉积位置、 旋转速度等方面对沉积坯形貌的影响进行定性的描述。 本文作者采用质量平均法[5], 建立了速度等高线模型, 通过速度等高线直观地给出了沉积位置、 回缩速度与沉积坯形貌的关系。 讨论了沉积位置和沉积器回缩速度对沉积棒坯形貌的影响, 采用二维坐标跟踪法计算了沉积棒坯二维剖面, 实验结果与预测得到了很好的吻合。

1 空间质量流率速度等高线模型

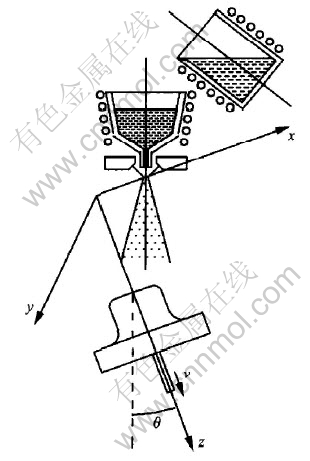

喷射成形过程中, 喷嘴竖直向下, 沉积器倾斜θ角旋转的同时向斜下方做回缩运动, θ角被称为喷射角, 如图1所示。 金属液流在距喷嘴很小的范围内被高压气体雾化成小液滴, 分布在以雾化点为顶点的圆锥内。 该雾化锥垂直平面内液滴的质量流率沿径向变化近似符合高斯分布[4, 7]:

图1 喷射成形过程示意图

Fig.1 Schematic illustration of spray forming

图2 喷射成形圆柱坯几何关系示意图

Fig.2 Schematic illustration of spray forming rocess for production of rod-billet

假设:

1)雾滴沿直线到达沉积坯表面, 金属流率沿径向在空间符合高斯分布。

2)沉积器高速旋转时(≥90°/s), 沉积坯的生长速度在同一圆周上是相等的, 而与初始相位没有关系[6, 10]。

3)沉积坯旋转一周的生长量在圆周上进行平均作为该半径上各点生长速度G[TX-]。

4)沉积坯的粘附系数SE为1。

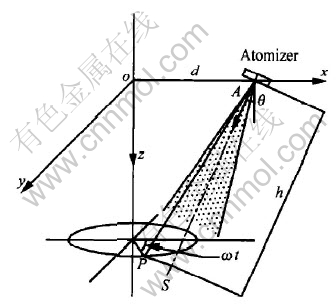

选取沉积器旋转轴为z轴, 雾化点到沉积器旋转轴的垂足为坐标原点, 坐标原点与雾化点所在直线为x轴(即柱面坐标系中的r轴), 坐标的选取如图2所示, 雾化点A坐标为(d, 0, 0)。 喷射轴AS的直线方程为

如图2所示, 距离沉积器旋转轴中心为R的一点P, 以其在x轴正方向的时刻为开始时刻, P点的坐标为(Rcos ωt, Rsin ωt, z), P点在任意时刻到雾化轴的距离D(即为图2中的PS)为[22]

D2=(Rsin ωt)2+[(Rcos ωt-d+ztan θ)cos θ]2(3)

式中 ω为沉积器的旋转角速度; ωt为半径R到x轴的正方向夹角; θ为喷射角。

沉积点P到雾化轴的垂足为S, S点到喷射点A的距离为h, 由勾股定理:

(AS)2=(AP)2-(PS)2(4)

由两点距离公式可求出AP, 代入PS的值D, 可得到:

h=(d-Ztan θ- Rcos ωt)sin θ+z/cos θ(5)

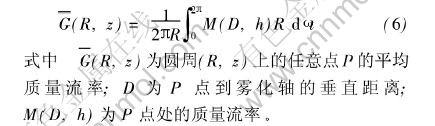

从而得到质量流率分布 为

为

通过计算不同(R, z)上的质量流率, 就得到整个空间的质量流率分布。 根据空间质量流率分布数据, 采用数值计算方法, 作出空间质量流率分布的速度等高线图。 速度等高线表示出沉积速度相同的Z、 R曲线, 每一条速度等高线形状就可以近似的看作是在沉积器处于该回缩速度时的沉积坯稳态准轮廓形貌[5]。 这对为选择合适的沉积距离和沉积器的回缩速度提供了依据。

采用二维坐标跟踪法[11, 12]得到沉积坯的二维轮廓。 由于所采用的沉积参数是在沉积器表面与喷射轴垂直时得到的, 当沉积坯生长时, 沉积表面与喷射轴的角度发生改变, 同时考虑到沉积过程中出现的遮挡效应和粘附系数, 所以沉积坯上表面任意点在沉积方向上的沉积速度可表示为

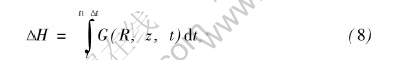

在Δt时间内, P点在喷射方向ef生长的高度ΔH为

若P点在t时刻的坐标为(Rr, z), 则t+Δt时刻的坐标(RΔt, zΔt)可以表示为

(RΔt=R+ΔH·(ef·eφ)·(eφ·eR)

ZΔt=z+ΔH·(ef·ez)(9)

式中 er、 ez分别为半径R及z轴反方向单位矢量; eφ为ef在z轴垂面的投影矢量。

2 结果与讨论

2.1 实验结果验证

喷射成形实验的原料为高硅铝合金, 铝合金的喷射温度为900℃。 采用限制型环孔雾化喷嘴、 N2雾化、 压力为0.8~1.2MPa。 实验测定了雾化锥的分布特征。 结果表明: 当h0=300mm时, 雾化系数A0=1.7mm/s, B0=0.0274mm-1。

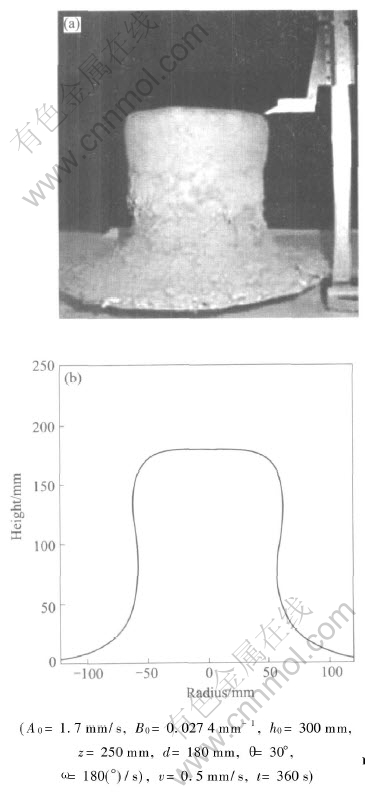

沉积过程中采用的沉积器旋转速度范围为30~60r/min, 得到的沉积坯形状如图3(a), 可以看出沉积坯仍能保持较好的旋转体外形, 这说明最初的假设是合理的。 图3(b)为模拟结果。 由图可见, 模拟结果与实验结果吻合较好, 说明该模型能够比较准确的预测圆柱坯的形状演化过程, 采用速度等高线确定的工艺参数是合理的。 模拟结果与实验结果的差异可能是由于实验过程中沉积速度的不稳定造成的。

图3 喷射成形360s获得的圆柱坯照片与模拟结果

Fig.3 Image of spray formed rod-billet(a), and alculated result(b)

2.2 沉积坯位置与回缩速度的选择

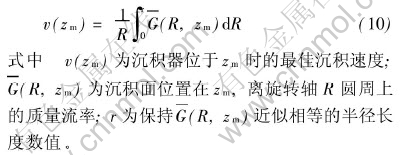

为了提高产率减少剥削量, 沉积坯端面最佳形状为一平面。 通过计算沉积器处于不同高度z时的沉积质量流率分布, 得到的沉积器处于位置z的沉积质量流率分布G, 随Rr呈一对称分布, 如图4中曲线1~3所示。 当沉积器距雾化点由近到远时, 在沉积器中心, 其质量流率有一最大值, 称为上限速度, 在该位置前后各有一位置其密度分布接近矩形分布, 沉积质量流率G随z不同存在最佳位置z, 在该位置沉积质量流率分布近似为矩形。 沉积坯端面各点生长速率相同, 沉积器处于该位置可沉积出端面平整的沉积坯, 此时矩形高度所示的G即为沉积坯的回缩速度v。 采用最小二乘法找出表面质量流率分布最均匀的沉积器位置zm和沉积质量平均密度。

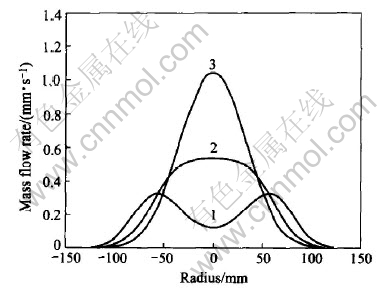

沉积质量流率分布随R和z的变化如图5所示。

图4 不同z时的沉积质量流率分布

Fig.4 Distributions of average droplet flow rate at different positions

图5 沉积器表面质量流率随z的变化

Fig.5 Variation of average droplet flow rate at surface of substrate with z

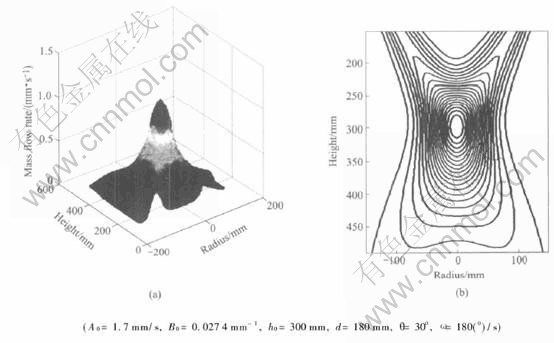

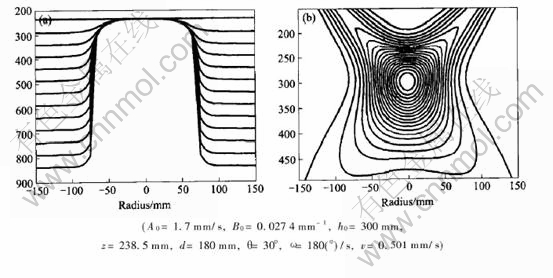

图6所示为喷射成形的空间质量流率分布和对应的速度等高线图。 从图6中可以看出沉积速度等高线为环型闭合曲线, 同一沉积速度的速度等高线在空间有两个位置近似水平平直, 在前一位置, 当沉积距离减小时, 对应位置的沉积速度变小, 沉积器回缩速度大于沉积坯表面的实际沉积速度, 沉积坯表面下降。 当沉积距离增加时, 对应位置的沉积速度变大, 沉积器回缩速度小于沉积坯表面的实际沉积速度, 沉积坯表面上升。 所以沉积速度的变化与相应的沉积坯表面位置的变化正好相反, 从而可以抵消沉积坯表面的波动, 故该位置为稳定的沉积位置。 在后一位置, 当沉积距离减小时, 对应位置的沉积速度增加, 沉积器回缩速度小于沉积坯表面的实际沉积速度, 沉积表面上升。 当沉积距离增加时, 对应位置的沉积速度减小, 沉积器回缩速度大于沉积坯表面的实际沉积速度, 沉积表面下降。 所以沉积坯表面沉积速度的变化与相应的沉积距离的变化相同, 增大了沉积表面的波动, 故该位置为不稳定的沉积位置(具体计算结果在下一节给出)。 图7所示为旋转400转后的稳定沉积坯轮廓空间位置与速度等高线的比较(沉积参数为z=238.5mm, v=0.501mm/s)。

从图7可以看出, 沉积轮廓与稳定沉积位置的速度等高线在端面部分是吻合的, 由于速度等高线是在端面为平面的情况下计算的, 没有考虑沉积端面倾角对沉积速度的影响, 所以在沉积坯的圆角处实际沉积速度比计算值大, 但这对于选择合适的沉积位置来说, 影响很小。 由于没有考虑沉积端面倾角对沉积速度的影响, 沉积坯的实际直径要大于速度等高线的宽度。

2.3 沉积器沉积位置和回缩速度对沉积坯稳态端面的影响

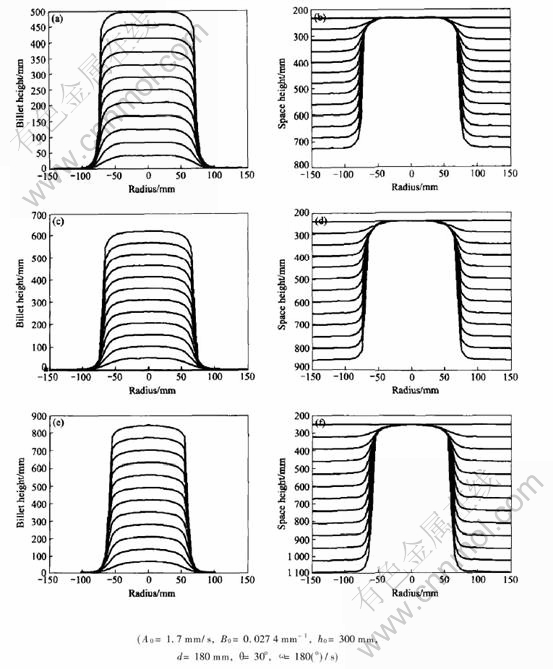

图8所示为稳定位置参数时的形状演化过程。

图6 质量流率三维分布与沉积速度等高线图

Fig.6 3-D droplet flow rate calculated(a) and droplet flow rate contour(b)

图7 沉积坯形貌与速度等高线的比较

Fig.7 Comparison between calculated profiles of

rod-billet(a) and droplet flow rate contour(b)

图8 沉积器位于稳定位置沉积坯的高度变化和轮廓的空间位置

Fig.8 Calculated rod-shape profiles(a), (c), (e) and location of

rod-shape surface(b), (d), (f) at 100s intervals

左图所示为沉积坯的高度变化图, 右图所示为沉积坯轮廓的空间位置图。 可以看出, 沉积端面经过一段时间后稳定在固定的空间位置。 随着回缩速度的增加, 圆柱坯中间区的直径减小。 在稳定沉积空间范围内, 回缩速度与沉积坯上表面的形貌是相对应的, 不同的回缩速度对应着不同的稳态上表面的形貌, 也对应着不同的空间位置。 尽管沉积器在不同的初始位置, 但达到稳态后, 沉积坯端面的空间位置总是与其回缩速度对应的。

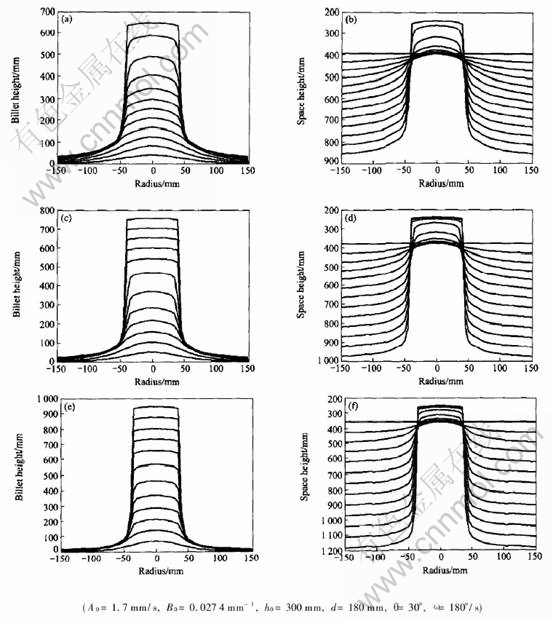

图9所示为采用非稳定位置参数时的形状演化过程, 左边是沉积坯的高度变化图, 右边是沉积坯轮廓的空间位置图。 从图9可以看出, 沉积端面在

图9 沉积器位于非稳定位置沉积坯的高度变化和轮廓的空间位置

Fig.9 Calculated rod-shape profiles(a), (c), (e) and location of

rod-shape surface(b), (d), (f) at 100s intervals

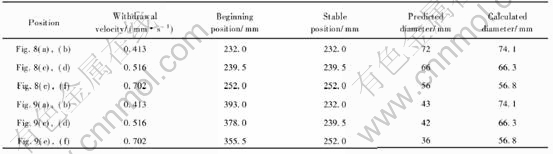

经过一段时间缓慢变化后, 然后快速变化, 在越过最大生长速度后, 停留在稳定位置。 随着回缩速度的增加, 圆柱坯中间区的直径减小。 对比结果见表1。 在非稳定位置时, 选取的沉积速度应略大于速度等高线的相应沉积位置, 否则沉积表面会离喷嘴越来越远, 导致最终无法成形。

同时与采用质量守恒[10, 23]方法计算公式(11), 得出的半径进行了对比, 沉积参数和比较结果列于表1。

从比较结果可以看出, 在稳定位置的沉积结果与公式计算结果吻合较好。

与稳定位置的沉积坯直径的对比可以得出, 非稳定位置的沉积坯直径要小于稳定位置的沉积坯直径。 这主要是由于非稳定位置距离喷嘴比较远, 所对应的雾化锥分布系数较小, 雾滴的分布范围较大, 不同沉积位置生长速度差异较小。 在随后的生长过程中, 沉积表面逐渐上升, 雾滴的分布越来越集中, 然后雾滴分布变宽, 最后沉积表面达到相应的稳定位置, 但由于最终的沉积端面与沉积过程是相关的, 所以得到的沉积坯直径较小。 对比与处于稳态位置得到的沉积坯可发现其边缘较厚, 说明有较大一部分雾滴沉积到边缘区。 从提高产率角度考虑, 沉积器处于非稳定位置作为初始沉积位置也是不经济的。

表1 沉积坯最终端面位置与沉积坯直径的对比

Table 1 Comparision of deposition stable position and rod diameter

对应的雾化锥分布系数较小, 雾滴的分布范围较大, 不同沉积位置生长速度差异较小。 在随后的生长过程中, 沉积表面逐渐上升, 雾滴的分布越来越集中, 然后雾滴分布变宽, 最后沉积表面达到相应的稳定位置, 但由于最终的沉积端面与沉积过程是相关的, 所以得到的沉积坯直径较小。 对比与处于稳态位置得到的沉积坯可发现其边缘较厚, 说明有较大一部分雾滴沉积到边缘区。 从提高产率角度考虑, 沉积器处于非稳定位置作为初始沉积位置也是不经济的。

3 结论

1)稳定沉积坯端面与相应位置的速度等高线是吻合的, 速度等高线表达出沉积器回缩速度与空间位置及稳定沉积坯轮廓的关系。

2)沉积器轴线上有一沉积质量流率最大值, 该位置前后各有一最佳沉积端面位置, 分别为稳定沉积位置和非稳定沉积位置。

3)沉积器位于稳定位置沉积, 沉积端面空间位置基本不变, 当沉积器位于非稳定位置沉积, 沉积端面空间位置会从非稳定位置过渡到稳定位置, 或不能沉积。

4)沉积坯端面形状主要由沉积器位置与相应的回缩速度决定。

REFERENCES

[1] Muhamad N, Medwell J O, Gethin D T. Model for predicting buildup of cylindrical billets in osprey perform process[J]. Powder Metallurgy, 1995, 38(3): 214-220.

[2] Aumund-Kopp C, Müller D H. Influencing the contour of spray-formed sheets and billets by changing the scanning kinematics of the atomizer[J]. Mater Sci Eng A, 2002, A326: 176-183.

[3] 张济山, 孙继跃, 崔 华, 等. 喷射沉积成形过程的优化控制(Ⅰ): 沉积坯件几何形状的控制(近终形成形)[J]. 材料导报, 1999, 13(1): 17-20.

ZHANG Ji-shan, SUN Ji-yue, CUI Hua, et al. Optimized control of spray forming process(Ⅰ): control of the shape of deposited preform(near-net shape)[J]. Materials Review, 1999, 13(1): 17-20.

[4] 张济山, 孙继跃, 崔 华, 等. 喷射沉积成形过程的优化控制(Ⅱ): 智能控制系统的发展[J]. 材料导报, 1999, 13(3): 6-9.

ZHANG Ji-shan, SUN Ji-yue, CUI Hua, et al. Optimized control of spray forming process(Ⅱ): development of intellective contol systems[J]. Materials Review, 1999, 13(3): 6-9.

[5] 霍 光, 邓德国, 谢 明, 等. 喷射成形棒坯中沉积距离和回缩速度的选择[J]. 粉末冶金技术, 2005, 23(2): 125-128.

HUO Guang, DENG De-guo, XIE Ming, et al. The selection of deposition distance and withdrawal velocity in spray forming[J]. Powder Metallurgy Technology, 2005.

[6] Seok H K, Lee H C, Oh K H, et al. Formulation of rod-forming models and their application in spray forming[J]. Metall Mater Trans A, 2000, 31A(5): 1479-1488.

[7] Seok H K, Yeo D H, Oh K H, et al. Three-dimensional model of the spray forming method[J]. Metall Mater Trans B, 1998, 29B(6): 699-708.

[8] Mathur P, Apelian D, Lawley A. Analysis of the spray deposition process[J]. Acta Metal, 1989, 37(2): 429-443.

[9] Mathur P, Annavarapu S, Apelian D, et al. Spray casting: an integral model for process understanding and control[J]. Mater Sci Eng A, 1991, A142: 261-276.

[10] Lin Y J, Bobrow J E, White D R, et al. Modeling of spray-formed materials: geometrical considerations[J]. Metall Mater Trans A, 1999, A31(11): 2917-2929.

[11] 曹福洋, 崔成松, 范洪波, 等. 喷射成形过程工艺参数作用规律的理论预测[J]. 中国有色金属学报, 1999, 9(2): 213-219.

CAO Fu-yang, CUI Cheng-song, FAN Hong-bo, et al. Theoretical analysis on effect of spray forming processing parameters[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 213-219.

[12] 曹福洋, 李培杰, 范洪波, 等. 喷射沉积柱状坯形状模型[J]. 材料科学与工艺, 2003, 11(1): 50-54.

CAO Fu-yang, LI Pei-jie, FAN Hong-bo, et al. Shape modeling of spray formed allumnar tillets[J]. Materials Science and Technology, 2003, 11(1): 50-54.

[13] Frigaard I A. The dynamics of spray-formed billets[J]. Siam J Appl Math, 1995, 55: 1161-1203.

[14] Frigaard I A, Scherzer O. Spraying the perfect billet[J]. Siam J Appl Math, 1997, 57: 649-682.

[15] Frigaard I A. Growth dynamics of an aluminium billets(part 1): steady state crown shapes[J]. J Mater Proc Manuf Sci, 1994, 3: 173-192.

[16] Frigaard I A. Growth dynamics of spray-formed aluminium billets(part 2): transient billet growth[J]. J Mater Proc Manuf Sci, 1995, 3: 257-275.

[17] Pedersen T B, Hattel J H, Pryds N H. A geometrical model for the prediction of the billet shape in spray forming[A]. Proceedings of the 22nd Ris International Symposium on Material Science: Science of Metastable and Nanocrystalline Alloys Structure, Properties and Modelling[C]. Riskilde, Denmark: Ris National Laboratory, 2001. 353-358.

[18] Hattel J H, Pryds N H, Pedersen T B. An integrated numerical model for the prediction of Gaussian and billet shapes[J]. Mater Sci Eng A, 2004, A383: 184-189.

[19] Markus S, Cui C, Fritsching U. Analysis of deposit growth in spray forming with multiple atomizers[J]. Mater Sci Eng A, 2004, A383: 166-174.

[20] 熊柏青, 张永安, 石力开. 雾化沉积棒坯的生长机制研究[J]. 金属学报, 1999, 35(2): 175-178.

XIONG Bai-qing, ZHANG Yong-an, SHI Li-kai. The research of spray forming technology of round buliets[J]. Acta Metall Sin, 1999, 35(2): 175-178.

[21] 熊柏青, 张永安, 林耀军, 等. 管坯的雾化沉积制备技术研究[A]. 李庆春, 沈 军. 98年全国喷射成形技术学术研讨会论文集[C]. 哈尔滨: 哈尔滨工业大学, 1998. 56-59.

XIONG Bai-qing, ZHANG Yong-an, LIN Yao-jun, et al. The research of spray forming techno-logy of tubes[A]. Li Qing-chun, SHEN Jun. Conference on spray forming of China (1998)[C]. Harbin: Harbin Institute of Technology, 1998. 56-59.

[22] 王连祥, 方德植, 张鸣铺, 等. 数学手册[M]. 北京: 高等教育出版社, 1990. 344.

WANG Lian-xiang, FANG De-zhi, ZHANG Ming-yong, et al. Handbook of Mathematics[M]. Beijing: Higher Education Press, 1990. 344.

[23] 刘东明. 喷射成形的计算机模拟与高强铝合金制备[D]. 沈阳: 中国科学院金属研究所, 2004.

LIU Dong-ming. Modeling of the Spray Forming Process and Manufacturing of High-strength Aluminum Alloys[D]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2004.

基金项目: 云南省自然科学基金资助项目(1999E0007Z); 云南省省院省校科技合作资助项目(2001ABBEA00A006)

收稿日期: 2005-01-21;

修订日期: 2005-06-06

作者简介: 霍 光(1974-), 男, 博士研究生.

通讯作者: 霍 光; 电话: 0871-5134234; E-mail: huoguang2000@163.com

(编辑 陈爱华)